Ceramic rock plate prepared from wollastonite tailings through ultralow-temperature fast firing and manufacturing method of ceramic rock plate

A manufacturing method and wollastonite technology, which are applied in the field of ceramic product manufacturing, can solve the problems of shortage of raw material resources, dark color of ceramic tiles, limited application, etc. The effect of ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The raw materials of the ceramic slate body, in parts by weight, include the following components:

[0073] 40 parts of wollastonite tailings, 35 parts of clay, 2 parts of potassium feldspar, 3 parts of albite, 10 parts of quartz, 2 parts of zirconium silicate, 5 parts of spodumene, 2 parts of monetite, 0.7 parts of sodium hexametaphosphate part, 0.3 part of modified lignin; among them, monetite needs to be calcined at 900 ℃ before use. Among them, the wollastonite tailings are composed as follows according to the weight percentage: wollastonite 47wt%, diopside 6wt%, calcite 28wt%, quartz 15wt%, other impurities 4wt%;

[0074] The ceramic slate body adopts a low-temperature fast-firing sintering process, the sintering temperature is 1080 ° C, and the sintering time is 50 minutes. The whiteness of the obtained ceramic slate body is greater than 58 degrees, the water absorption rate is 0.08%, and the fracture modulus is 58MPa.

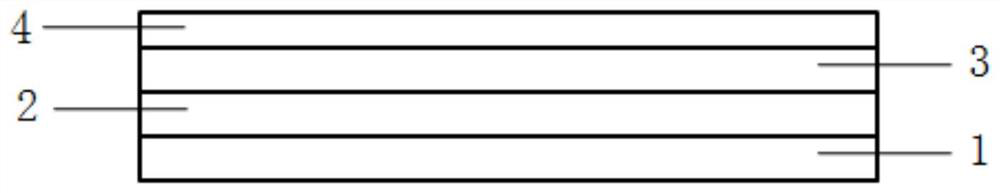

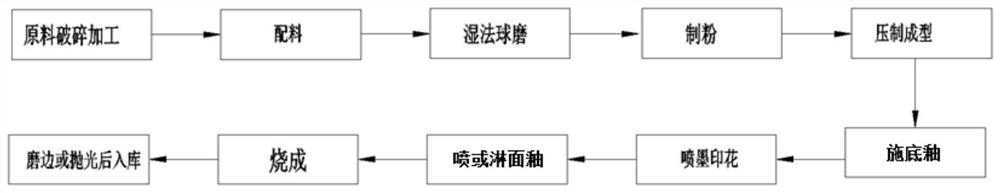

[0075] Preparation of ceramic slate (such...

Embodiment 2

[0087] The raw materials of the ceramic slate body, in parts by weight, include the following components:

[0088] 30 parts of wollastonite tailings, 40 parts of clay, 9 parts of potassium albite, 15 parts of quartz, 1 part of zirconium silicate, 3 parts of spodumene, 1 part of monetite, 0.7 parts of sodium tripolyphosphate, modified wood 0.3 servings of vegetarian food.

[0089] Among them, the wollastonite tailings are composed as follows according to the weight percentage: wollastonite 45wt%, diopside 4wt%, calcite 30wt%, quartz 15wt%, other 6wt%;

[0090] The ceramic slate body adopts a low-temperature fast-firing sintering process, the sintering temperature is 1055°C, and the sintering time is 45 minutes. The obtained ceramic slate body has a whiteness greater than 50 degrees, a water absorption rate of 2.4%, and a modulus of rupture. is 43MPa.

[0091] Preparation of ceramic slate (such as figure 2 shown):

[0092] (1) Crushing and processing of raw materials. The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com