Rock plate with fine skin feeling and preparation method thereof

A delicate and skin-friendly technology, applied in the field of slate with delicate skin and its preparation, can solve the problems of rough surface, insufficient gloss and fineness, etc., achieve natural and soft luster, good matte effect, and improve uniformity and compactness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

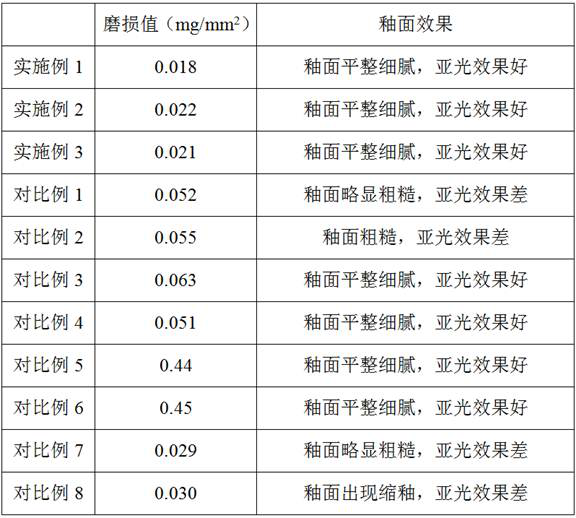

Examples

Embodiment 1

[0030] A rock slab with a delicate skin feeling, which includes a body layer, an underglaze layer, and a matte layer from bottom to top, and the matte layer is formed by spraying matte glaze and sintering at 1200°C; the matte glaze Spraying amount is 500g / m 2 ;

[0031] The matte glaze is formed by mixing the following raw materials in parts by weight: 36.3 parts of albite, 22 parts of transparent frit, 15 parts of matt frit, 9 parts of zirconium silicate, 6 parts of modified graphene, 5 parts of titanium dioxide, 3 parts of calcium oxide, 2 parts of zirconium dioxide, 1.2 parts of zinc oxide, 0.5 parts of sodium tripolyphosphate.

[0032] The transparent frit is made of the following raw materials in parts by weight: 32 parts of anorthite, 24 parts of potassium feldspar, 18 parts of quartz, 12 parts of kaolin, 4 parts of silicon dioxide, 3 parts of borax, 3 parts of silica powder, 1.8 parts White carbon black, 1.3 parts of zinc oxide, 0.9 parts of antimony trioxide.

[003...

Embodiment 2

[0046] A rock slab with a delicate skin feeling, which includes a body layer, an underglaze layer, and a matte layer from bottom to top, and the matte layer is formed by spraying matte glaze and sintering at 1200°C; the matte glaze Spraying amount is 500g / m 2 ;

[0047] The matte glaze is formed by mixing the following raw materials in parts by weight: 30 parts of albite, 20 parts of transparent frit, 12 parts of matt frit, 6 parts of zirconium silicate, 5 parts of modified graphene, 4 parts of titanium dioxide, 2 parts of calcium oxide, 1 part of zirconium dioxide, 1 part of zinc oxide, 0.2 parts of sodium tripolyphosphate.

[0048] The transparent frit is made of the following raw materials in parts by weight: 32 parts of anorthite, 24 parts of potassium feldspar, 18 parts of quartz, 12 parts of kaolin, 4 parts of silicon dioxide, 3 parts of borax, 3 parts of silica powder, 1.8 parts White carbon black, 1.3 parts of zinc oxide, 0.9 parts of antimony trioxide.

[0049] The...

Embodiment 3

[0062] A rock slab with a delicate skin feeling, which includes a body layer, an underglaze layer, and a matte layer from bottom to top, and the matte layer is formed by spraying matte glaze and sintering at 1200°C; the matte glaze Spraying amount is 500g / m 2 ;

[0063] The matte glaze is formed by mixing the following raw materials in parts by weight: 40 parts of albite, 25 parts of transparent frit, 14 parts of matte frit, 10 parts of zirconium silicate, 6 parts of modified graphene, 8 parts of titanium dioxide, 5 parts calcium oxide, 4 parts zirconium dioxide, 2 parts zinc oxide, 1 part sodium tripolyphosphate.

[0064] The transparent frit is made of the following raw materials in parts by weight: 32 parts of anorthite, 24 parts of potassium feldspar, 18 parts of quartz, 12 parts of kaolin, 4 parts of silicon dioxide, 3 parts of borax, 3 parts of silica powder, 1.8 parts White carbon black, 1.3 parts of zinc oxide, 0.9 parts of antimony trioxide.

[0065] The matt frit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com