High-strength electric-porcelain ash glaze formula and its preparation method

A high-strength, electric porcelain technology, applied in the field of electric porcelain gray glaze formula and its preparation, can solve the problems of electric porcelain mechanical, electrical, and thermal performance, and can not greatly improve the bending strength of porcelain, so as to achieve smooth and flat product surface , excellent workmanship and improved appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 :New high-strength electric porcelain brown glaze formula, including white glaze base material and color material. The white glaze base material includes the following components and the weight parts of each component are: 25 parts of potash feldspar, 27 parts of quartz, and Xinhui powder 9 parts, 5 parts of washed kaolin, 6 parts of Xingzi kaolin, 8 parts of talc, 5 parts of limestone, 4 parts of levorotite, 3 parts of zirconium silicate, 8 parts of alumina, and the quality of the pigment is white glaze base material 20% by mass, and the colorant includes the following components, and the weight parts of each component are respectively: 45 parts of zinc oxide, 20 parts of chromium oxide, and 35 parts of cobalt oxide.

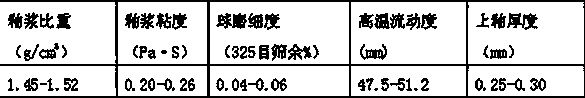

[0029] The preparation method of high-strength electric porcelain glaze includes the following steps:

[0030] (1) Preparation of pigments: mix 45 parts by weight of zinc oxide, 20 chromium oxide, and 35 cobalt oxide, and calcinate at a temperature ...

Embodiment 2

[0039] New high-strength electric porcelain brown glaze formulation, including white glaze base material and colorant. The white glaze base material includes the following components and the weight parts of each component are: 24 parts of potash feldspar, 29 parts of quartz, and 8 parts of Xinhui powder Parts, 9 parts of washed kaolin, 8 parts of Xingzi kaolin, 12 parts of talc, 4 parts of limestone, 6 parts of levorotite, 6 parts of zirconium silicate, 15 parts of alumina, and the quality of the pigment is the quality of the white glaze base material The colorant includes the following components and the weight parts of each component are respectively: 35 parts of zinc oxide, 10 parts of chromium oxide, and 40 parts of cobalt oxide.

[0040] The preparation method of the electric porcelain glaze described in this embodiment is the same as that of the embodiment 1.

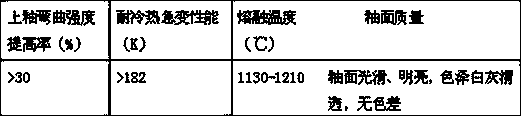

[0041] For the gray glaze produced according to the components and parts by weight ratio of this embodiment, the ele...

Embodiment 3

[0048] New high-strength electric porcelain brown glaze formulation, including white glaze base material and colorant. The white glaze base material includes the following components and the weight parts of each component are: 27 parts of potash feldspar, 25 parts of quartz, and 15 parts of Xinhui powder Parts, 7 parts of washed kaolin, 5 parts of Xingzi kaolin, 15 parts of talc, 7 parts of limestone, 8 parts of levonite, 4 parts of zirconium silicate, 5 parts of alumina, and the quality of the pigment is the quality of the white glaze base material The pigment includes the following components and the weight parts of each component are respectively: 55 parts of zinc oxide, 4 parts of chromium oxide, and 25 parts of cobalt oxide.

[0049] The preparation method of the electric porcelain glaze described in this embodiment is the same as that of the embodiment 1.

[0050] For the gray glaze produced according to the components and parts by weight ratio of this embodiment, the electri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com