Waste porcelain powder doped matt color glaze, ceramic product and preparation method

A technology of waste porcelain powder and glaze, which is applied in the field of ceramics, can solve the problems of affecting the quality of ceramic products and unstable color rendering, and achieve stable color rendering effects and a wide firing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

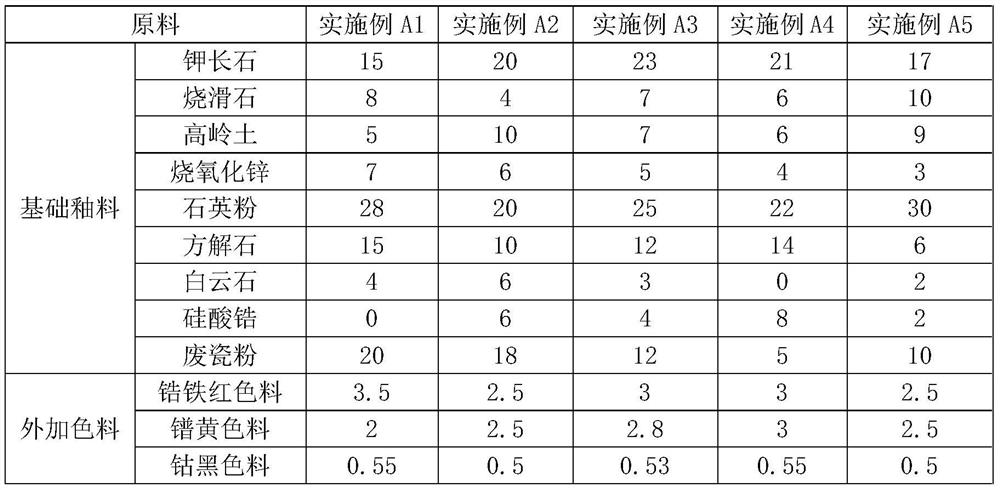

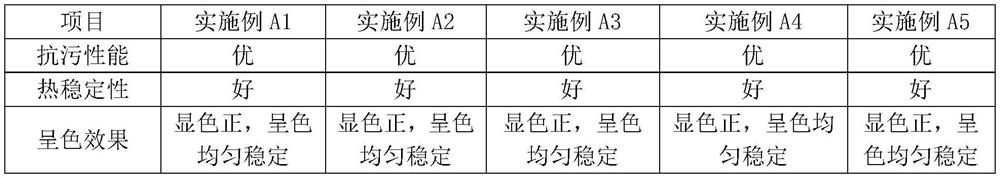

Examples

preparation example Construction

[0035] The present invention also provides a kind of preparation method of ceramic product, comprises the following steps:

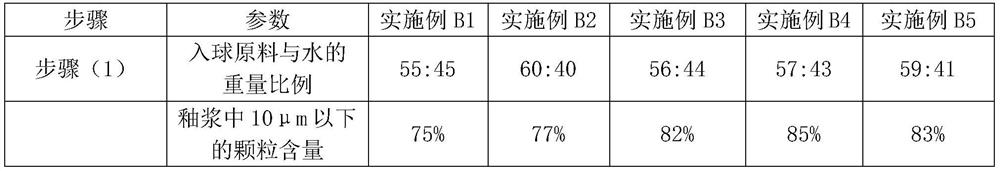

[0036] (1) Add each raw material of the base glaze of the matt color glaze mixed with waste porcelain powder and the additional coloring material into a ball mill according to the formula ratio and carry out wet ball milling to obtain the glaze slurry. The content of particles below 10 μm in the glaze slurry is 75-85%;

[0037] (2) Applying the glaze slurry obtained in step (1) to the surface of the molded body by spraying glaze;

[0038] (3) into the kiln and fired.

[0039] The preparation method of the ceramic product of the present invention has the characteristics of simple process and easy control, and can obtain the ceramic product with stable glaze color and positive color development. Preferably, the ceramic product is a sanitary ware.

[0040] Further, in step (1), during wet ball milling, the weight ratio of the ball-into raw material and w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com