Low temperature high silicon stoneware and its making process

A technology of stoneware and high silicon, applied in the field of stoneware in ceramics, can solve problems such as glaze cracks, cracks, and deficiencies, and achieve the effects of small firing shrinkage, low production cost, and increased expansion coefficient and strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

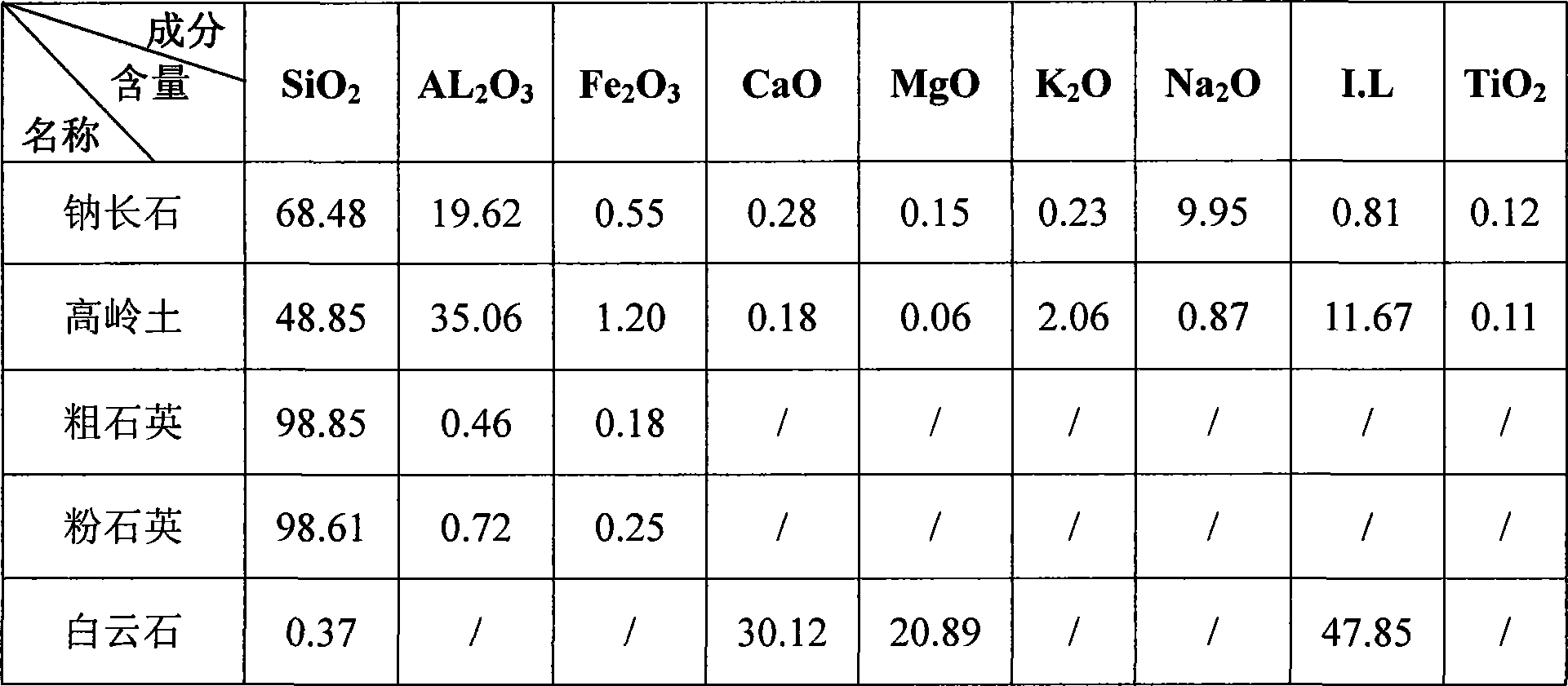

[0027] A kind of high-silicon stoneware, the main representative mineral composition is feldspar, kaolin, quartz and dolomite, and the proportion of each composition is as follows:

[0028] Albite 15%, Kaolin 35%, Quartz 45%, Dolomite 5%

[0029] The firing process of the high-silicon stoneware is the same as that of ordinary stoneware, the firing temperature range is 1175-1225°C, and the water absorption rate is controlled between 1-4%.

Embodiment 2

[0031] A kind of high-silicon stoneware, the main representative mineral composition is feldspar, kaolin, quartz and dolomite, and the proportion of each composition is as follows:

[0032] Albite 30%, Kaolin 29%, Quartz 40%, Dolomite 1%

[0033] The firing process of the high-silicon stoneware is the same as that of ordinary stoneware, the firing temperature range is 1175-1225°C, and the water absorption rate is controlled between 1-4%.

[0034] The ideal chemical composition obtained by the proportioning of above-mentioned embodiment is:

[0035] SiO2: 72-79% Al2O3: 14.5-18% Fe2O3: 0.5-1.5%

[0036] TiO2: 0.1~1.5% CaO+MgO: 0.3~2.5% K2O: 0.2~1%

[0037] Na2O: 1.5-3.5% I.L: 4.0-6.5% The rest are impurities.

Embodiment 3

[0039] Ideal formula of the present invention is as follows:

[0040] Albite 25% Kaolin 32% Coarse Quartz 31.5%

[0041] Superfine Quartz 10% Dolomite 1.5%

[0042] The chemical composition of green body is:

[0043] SiO2: 74.25% Fe2O3: 0.73% Al2O3: 16.08%

[0044] TiO2: 0.15% CaO: 0.61% MgO: 0.31%

[0045] K2O: 0.62% Na2O: 2.68% I.L: 4.5

[0046] The expansion coefficient is 8.26×10-6.

[0047] The firing process of the high-silicon stoneware is the same as that of ordinary stoneware, the firing temperature range is 1175-1225°C, and the water absorption rate is controlled between 1-4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com