Method for preparing carbon/carbon composite zirconium silicate/silicon carbide antioxidant coating

A carbon composite material and anti-oxidation coating technology, applied in the field of C/C composite material preparation, can solve the problems of low oxygen permeability, complicated preparation process, difficulty in obtaining pure yttrium silicate, etc., and achieve easy-to-obtain raw materials , The effect of simple process preparation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

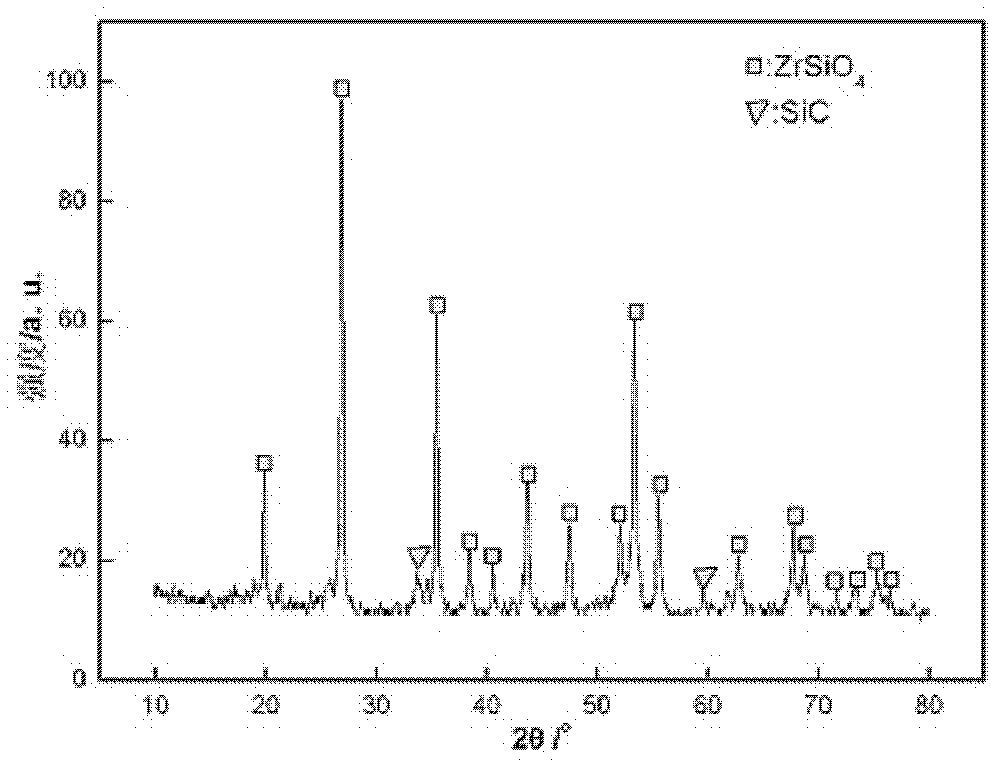

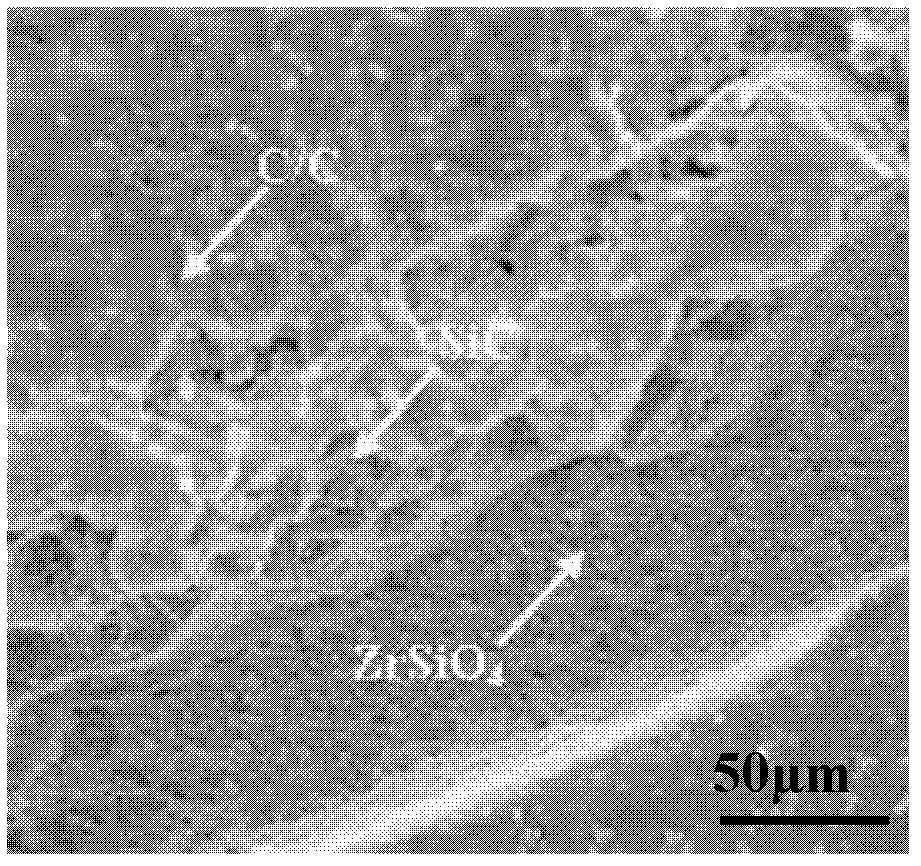

Image

Examples

Embodiment 1

[0019] 1) Pretreatment of carbon / carbon composite materials: use 2D-carbon / carbon composite materials used in aircraft brake pads and process them into 10×10×10mm 3 The samples were subjected to surface treatment of grinding and chamfering, then cleaned with absolute ethanol in an ultrasonic generator, and dried in an oven;

[0020] 2) Preparation of silicon carbide transition layer: take commercially available silicon powder and graphite powder, and mix them uniformly at a mass ratio of Si powder:graphite powder=2:1 to obtain powder A;

[0021] 3) Take commercially available Al 2 o 3 Powder, Ta 2 o 5 Powder, WO 3 Powder, B 2 o 3 Powder, by Al 2 o 3 Powder: Ta 2 o 5 Powder: WO 3 Powder: B 2 o 3 The mass ratio of powder=1:1:2:3 is mixed evenly to obtain powder B;

[0022] 4) Mixing according to the mass ratio of powder A: powder B = 2: 1 to obtain powder C for embedding;

[0023] 5) Then put the carbon / carbon sample into the graphite crucible, and add embedding p...

Embodiment 2

[0027] 1) Pretreatment of carbon / carbon composite materials: use 2D-carbon / carbon composite materials used in aircraft brake pads and process them into 10×10×10mm 3 The samples were subjected to surface treatment of grinding and chamfering, then cleaned with absolute ethanol in an ultrasonic generator, and dried in an oven;

[0028] 2) Preparation of silicon carbide transition layer: take commercially available silicon powder and graphite powder, and mix them uniformly at a mass ratio of Si powder:graphite powder=1:3 to obtain powder A;

[0029] 3) Take commercially available Al 2 o 3 Powder, Ta 2 o 5 Powder, WO 3 Powder, B 2 o 3 Powder, by Al 2 o 3 Powder: Ta 2 o 5 Powder: WO 3 Powder: B 2 o 3 The mass ratio of powder=3:4:6:7 is mixed evenly to obtain powder B;

[0030] 4) Mixing according to the mass ratio of powder A: powder B = 1: 1 to obtain powder C for embedding;

[0031] 5) Then put the carbon / carbon sample into the graphite crucible, and add embedding p...

Embodiment 3

[0034] 1) Pretreatment of carbon / carbon composite materials: use 2D-carbon / carbon composite materials used in aircraft brake pads and process them into 10×10×10mm 3 The samples were subjected to surface treatment of grinding and chamfering, then cleaned with absolute ethanol in an ultrasonic generator, and dried in an oven;

[0035] 2) Preparation of silicon carbide transition layer: take commercially available silicon powder and graphite powder, and mix them uniformly at a mass ratio of Si powder:graphite powder=8:1 to obtain powder A;

[0036] 3) Take commercially available Al 2 o 3 Powder, Ta 2 o 5 Powder, WO 3 Powder, B 2 o 3 Powder, by Al 2 o 3 Powder: Ta 2 o 5 Powder: WO 3 Powder: B 2 o 3 The mass ratio of powder=2:3:1:1 is mixed evenly to obtain powder B;

[0037] 4) Mixing according to the mass ratio of powder A: powder B = 1:6 to obtain powder C for embedding;

[0038] 5) Then put the carbon / carbon sample into the graphite crucible, and add embedding po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com