Jun porcelain iron sand gold glaze and preparation method thereof

A technology of iron sand and gold glaze, applied in the field of Jun porcelain iron sand gold glaze and its preparation, can solve the problems of few iron sand gold glaze formulas and preparation methods, low mechanical strength, poor gloss, etc., and achieves strong reproducibility and gloss. High degree, smooth glaze effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

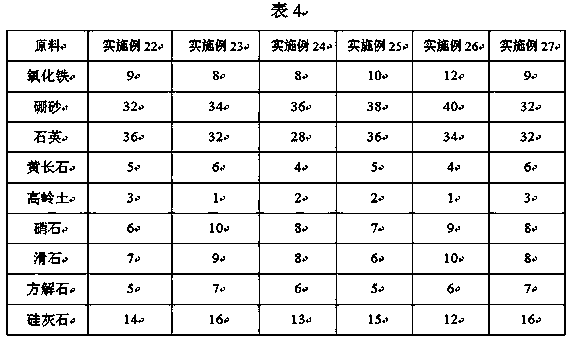

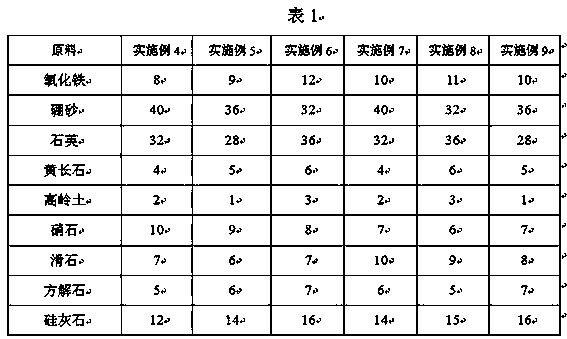

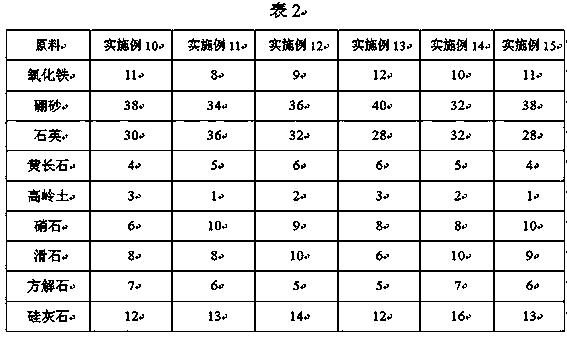

[0020] A Jun porcelain iron place gold glaze, which is prepared from the following raw materials in parts by weight: 8-12 parts of iron oxide, 32-40 parts of borax, 28-36 parts of quartz, 4-6 parts of feldspar, and 1-3 parts of kaolin , 6-10 parts of saltpeter, 6-10 parts of talc, 5-7 parts of calcite, and 12-16 parts of wollastonite.

[0021] The preparation method of described Jun porcelain iron placer gold glaze, comprises the following steps:

[0022] (1) Crush the above raw materials and put them into a ball mill for ball milling, add water to make the mass concentration of the glaze reach 50-52%, wet mill for 6-8 hours, pass the wet milled slurry through a 200-300 mesh sieve to obtain glaze slurry ;

[0023] (2) The green body is dipped in glaze for 2-3 times;

[0024] (3) Firing, the firing temperature is 1060-1120°C;

[0025] (4) Preserve at 960-1000°C for 30-60 minutes, anneal and cool to room temperature to prepare.

[0026] The invention uses borax as the main s...

Embodiment 2

[0028] A Jun porcelain iron placer gold glaze, which is prepared from the following raw materials in parts by weight: 10 parts of iron oxide, 36 parts of borax, 32 parts of quartz, 5 parts of feldspar, 2 parts of kaolin, 8 parts of saltpeter, 8 parts of talc, and calcite 6 parts, wollastonite 14 parts.

[0029] The preparation method of described Jun porcelain iron placer gold glaze, comprises the following steps:

[0030] (1) Grind the above raw materials and put them into a ball mill for ball milling, add water to make the mass concentration of the glaze reach 51%, wet mill for 7 hours, pass the wet milled slurry through a 250-mesh sieve to obtain the glaze slurry;

[0031] (2) The green body is dipped in glaze for 3 times;

[0032] (3) Firing, the firing temperature is 1090°C;

[0033] (4) Insulated at 980°C for 45 minutes, annealed and cooled to room temperature, and prepared.

[0034] In the preparation method of Jun porcelain iron placer gold glaze, the firing process...

Embodiment 3

[0039] A Jun porcelain iron placer gold glaze, which is prepared from the following raw materials in parts by weight: 9 parts of iron oxide, 34 parts of borax, 32 parts of quartz, 5 parts of feldspar, 3 parts of kaolin, 9 parts of saltpeter, 7 parts of talc, and calcite 5 parts, wollastonite 15 parts.

[0040] The preparation method of described Jun porcelain iron placer gold glaze, comprises the following steps:

[0041] (1) Grind the above raw materials and put them into a ball mill for ball milling, add water to make the mass concentration of the glaze reach 52%, wet mill for 6.5 hours, pass the wet milled slurry through a 300-mesh sieve to obtain the glaze slurry;

[0042] (2) The green body is dipped in glaze twice;

[0043] (3) Firing, the firing temperature is 1080°C;

[0044] (4) Insulated at 970°C for 50 minutes, annealed and cooled to room temperature, and prepared.

[0045] In the preparation method of Jun porcelain iron placer gold glaze, the firing process in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com