Lujun glaze

A technology of Lu Jun glaze and glaze slurry, applied in the field of Lu Jun glaze, can solve the problem of low success rate, easy loss of glaze, and one kiln can only fire one large blank or 2-3 small blanks problems such as tires, to achieve the effect of rich glaze color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

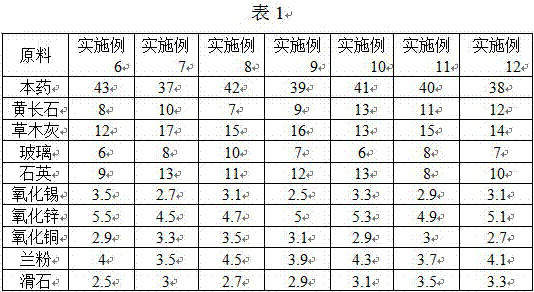

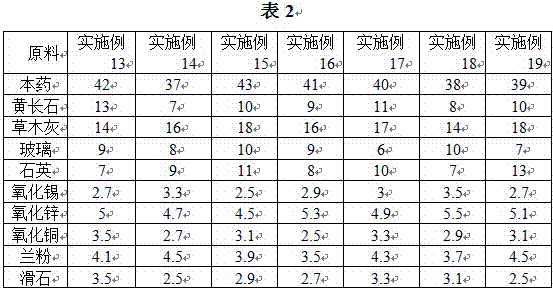

[0024] A Lujun glaze prepared from the following raw materials in parts by weight: 37-43 parts of this medicine, 7-13 parts of feldspar, 12-18 parts of plant ash, 6-10 parts of glass, 7-13 parts of quartz, and 2.5 parts of tin oxide -3.5 parts, zinc oxide 4.5-5.5 parts, copper oxide 2.5-3.5 parts, blue powder 3.5-4.5 parts, talc 2.5-3.5 parts.

[0025] The preparation method of above-mentioned Lu Jun glaze comprises the following steps:

[0026] (1) Preparation of glaze slurry; specifically includes the following steps: ① Plant ash elutriation: prepare several large vats during elutriation, pour an appropriate amount of water into one of the large vats, then add plant ash, and fully stir with a wooden stick , Stir all the plant ash, remove all the charcoal blocks and grass clippings floating on the water surface, stir the plant ash water again to make it in a suspended state, and some larger soil particles, stones, slag and other impurities will settle Go to the bottom of the...

Embodiment 2

[0030] A Lujun glaze prepared from the following raw materials in parts by weight: 40 parts of this medicine, 10 parts of feldspar, 15 parts of plant ash, 8 parts of glass, 10 parts of quartz, 3 parts of tin oxide, 55 parts of zinc oxide, and 3 parts of copper oxide 4 parts, blue powder 4 parts, talcum 3 parts.

[0031] The preparation method of above-mentioned Lu Jun glaze comprises the following steps:

[0032] (1) Preparation of glaze slurry, the specific preparation steps are the same as in Example 1;

[0033] (2) Glazing is applied on the biscuit body by dipping;

[0034] (3) Firing, the firing temperature is 1280°C; specifically includes the following steps: ①Slow heating stage: put the body after glaze application into the kiln, so that the temperature rises to 450°C evenly within 2 hours; ②Rapid heating stage: Under an oxygen atmosphere, the temperature was raised uniformly to 900°C in 15 minutes; ③ reduction firing stage: the temperature was raised to 1280°C uniform...

Embodiment 3

[0037] A Lujun glaze prepared from the following raw materials in parts by weight: 40 parts of this medicine, 10 parts of feldspar, 15 parts of plant ash, 8 parts of glass, 10 parts of quartz, 3 parts of tin oxide, 55 parts of zinc oxide, and 3 parts of copper oxide 4 parts, blue powder 4 parts, talcum 3 parts.

[0038] The preparation method of above-mentioned Lu Jun glaze comprises the following steps:

[0039] (1) Preparation of glaze slurry, the specific preparation steps are the same as in Example 1;

[0040] (2) Glazing is applied on the biscuit body by dipping;

[0041] (3) Firing, the firing temperature is 1300°C; specifically includes the following steps: ①Slow heating stage: put the glazed green body into the kiln, so that the temperature rises to 430°C evenly in 1.5h; ②Rapid heating stage : Under an oxygen atmosphere, the temperature is evenly raised to 900°C in 20 minutes; ③Reduction firing stage: The temperature is evenly raised to 1300°C in 10 minutes, and kept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com