Low dielectric glass fiber component and production method thereof

A technology of glass fiber and manufacturing method, applied in the field of electronic information substrate materials, can solve problems such as polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

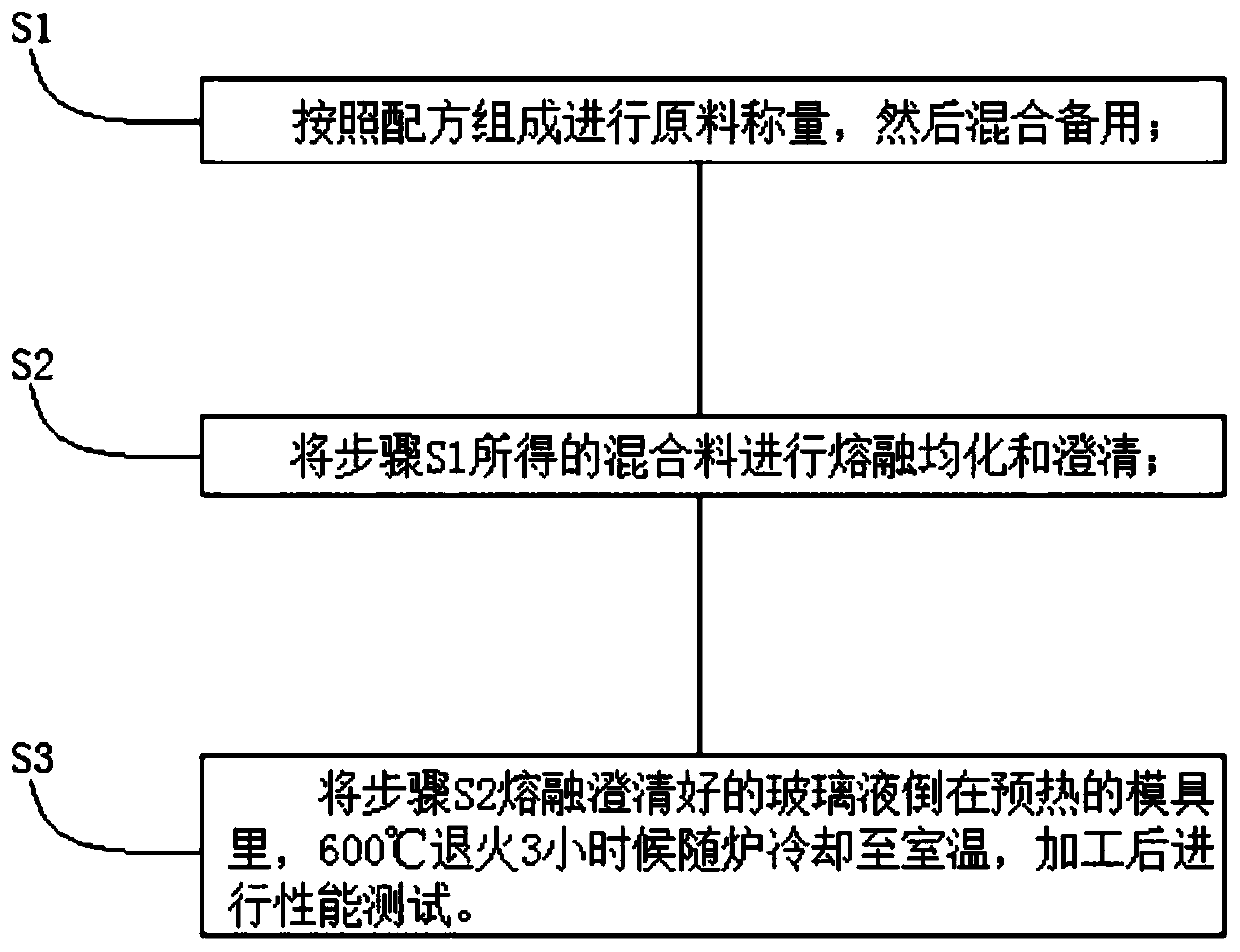

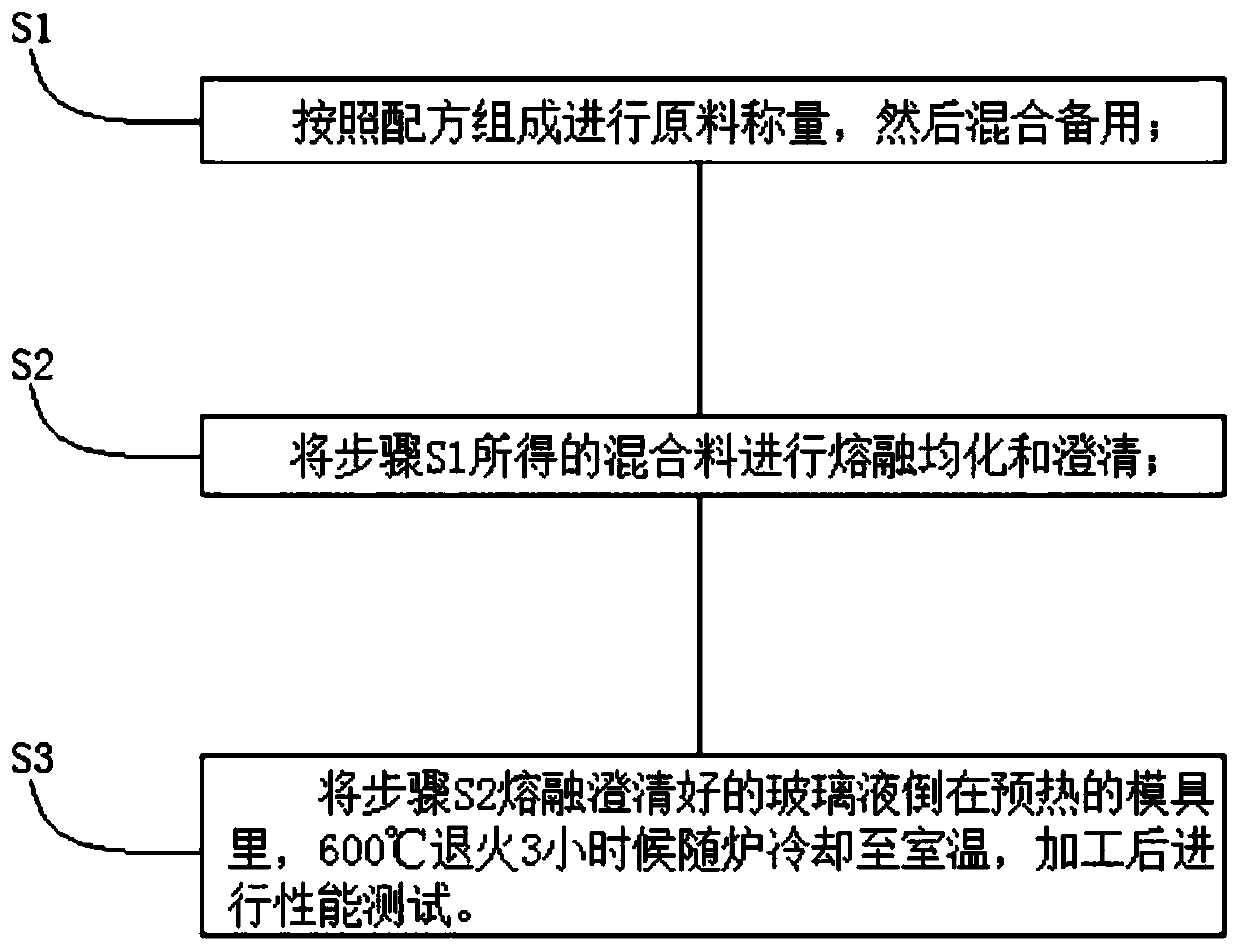

Method used

Image

Examples

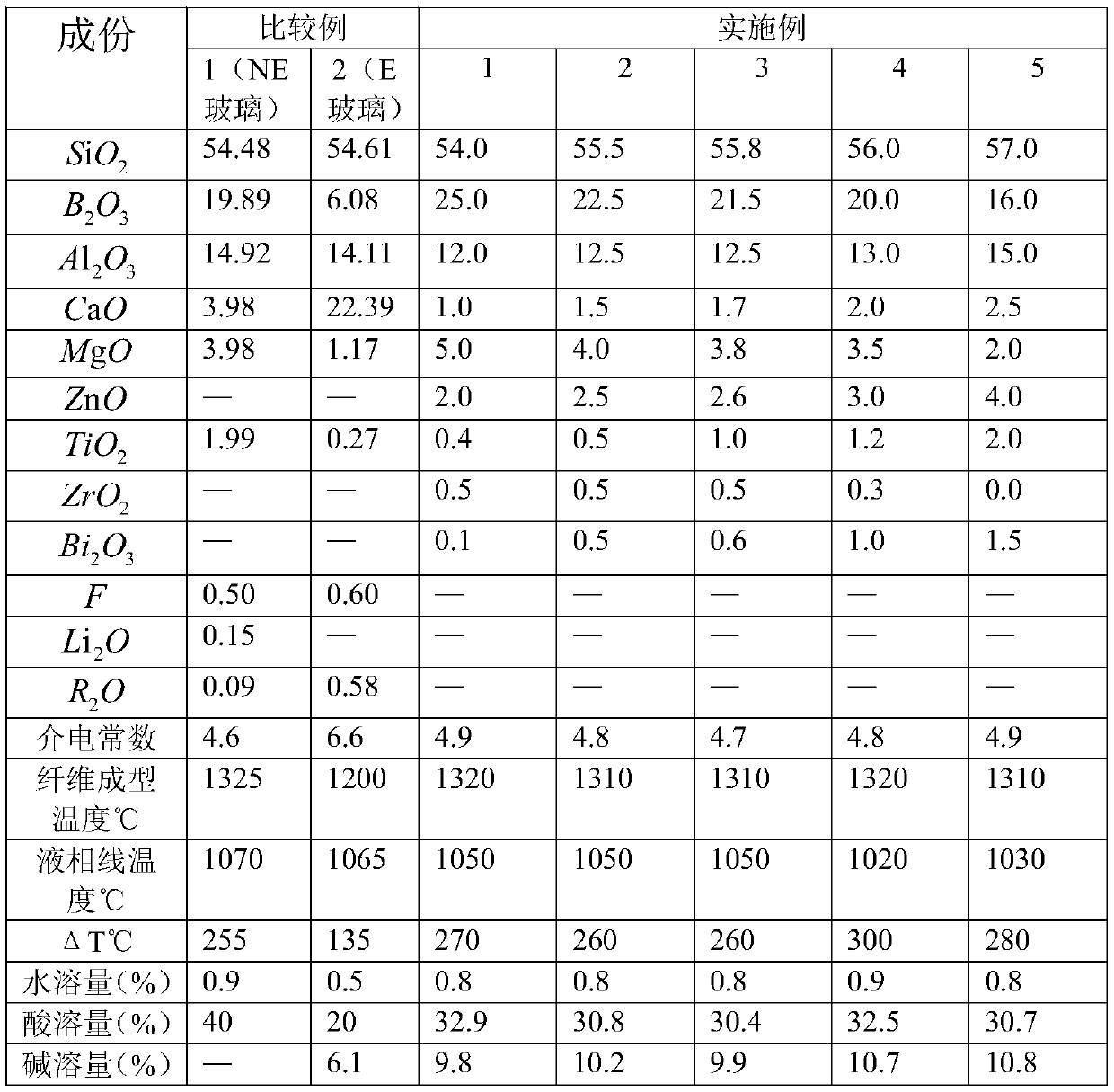

Embodiment 1

[0040] A low dielectric glass fiber component, by mass fraction, includes the following components:

[0041] SiO 2 :54.0%, Al 2 o 3 : 12.0%, B 2 o 3 : 25.0%, CaO: 1.0%, MgO: 5.0%, ZnO: 2.0%, TiO 2 : 0.4%, ZrO 2 : 0.5%, Bi 2 o 3 : 0.1%.

[0042] The dielectric constant is 4.9, the fiber forming temperature is 1320°C, the liquidus temperature is 1050°C, the △T is 270°C, the water solubility is 0.8%, the acid solubility is 32.9%, and the alkali solubility is 9.8%.

Embodiment 2

[0044] A low dielectric glass fiber component, by mass fraction, includes the following components:

[0045] SiO 2 :55.5%, Al 2 o 3 : 12.5%, B 2 o 3 : 22.5%, CaO: 1.5%, MgO: 4.0%, ZnO: 2.5%, TiO 2 : 0.5%, ZrO 2 : 0.5%, Bi 2 o 3 : 0.5%.

[0046] The dielectric constant is 4.8, the fiber forming temperature is 1310°C, the liquidus temperature is 1050°C, the △T is 260°C, the water solubility is 0.8%, the acid solubility is 30.8%, and the alkali solubility is 10.2%.

Embodiment 3

[0048] A low dielectric glass fiber component, by mass fraction, includes the following components:

[0049] SiO 2 :55.8%, Al 2 o 3 : 12.5%, B 2 o 3 : 21.5%, CaO: 1.7%, MgO: 3.8%, ZnO: 2.6%, TiO 2 : 1.0%, ZrO 2 : 0.5%, Bi 2 o 3 : 0.6%.

[0050] The dielectric constant is 4.7, the fiber forming temperature is 1310°C, the liquidus temperature is 1050°C, the △T is 260°C, the water solubility is 0.8%, the acid solubility is 30.4%, and the alkali solubility is 9.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dielectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com