Glass powder for copper conductive paste, preparation method and application thereof

A technology of conductive paste and glass powder, used in circuits, capacitors, electrical components, etc., can solve the problems of increasing the stress of the ceramic body and the metal terminal electrode, reducing the insulation resistance, and cracking the terminal, so as to prevent vitrification defects, high High temperature viscosity, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with specific examples.

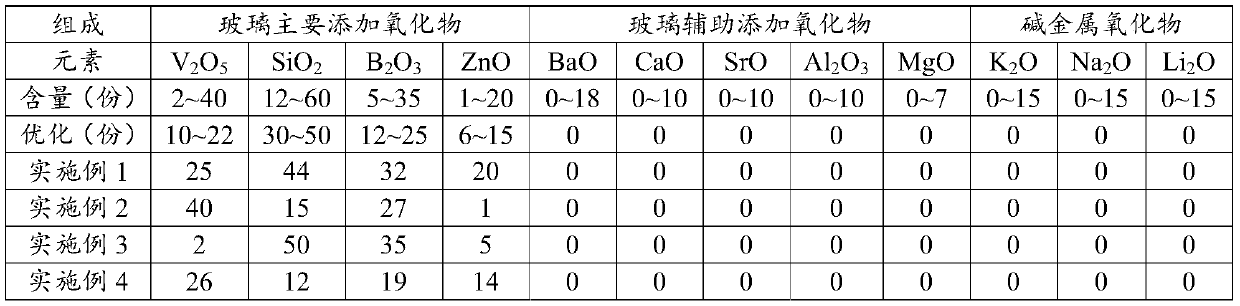

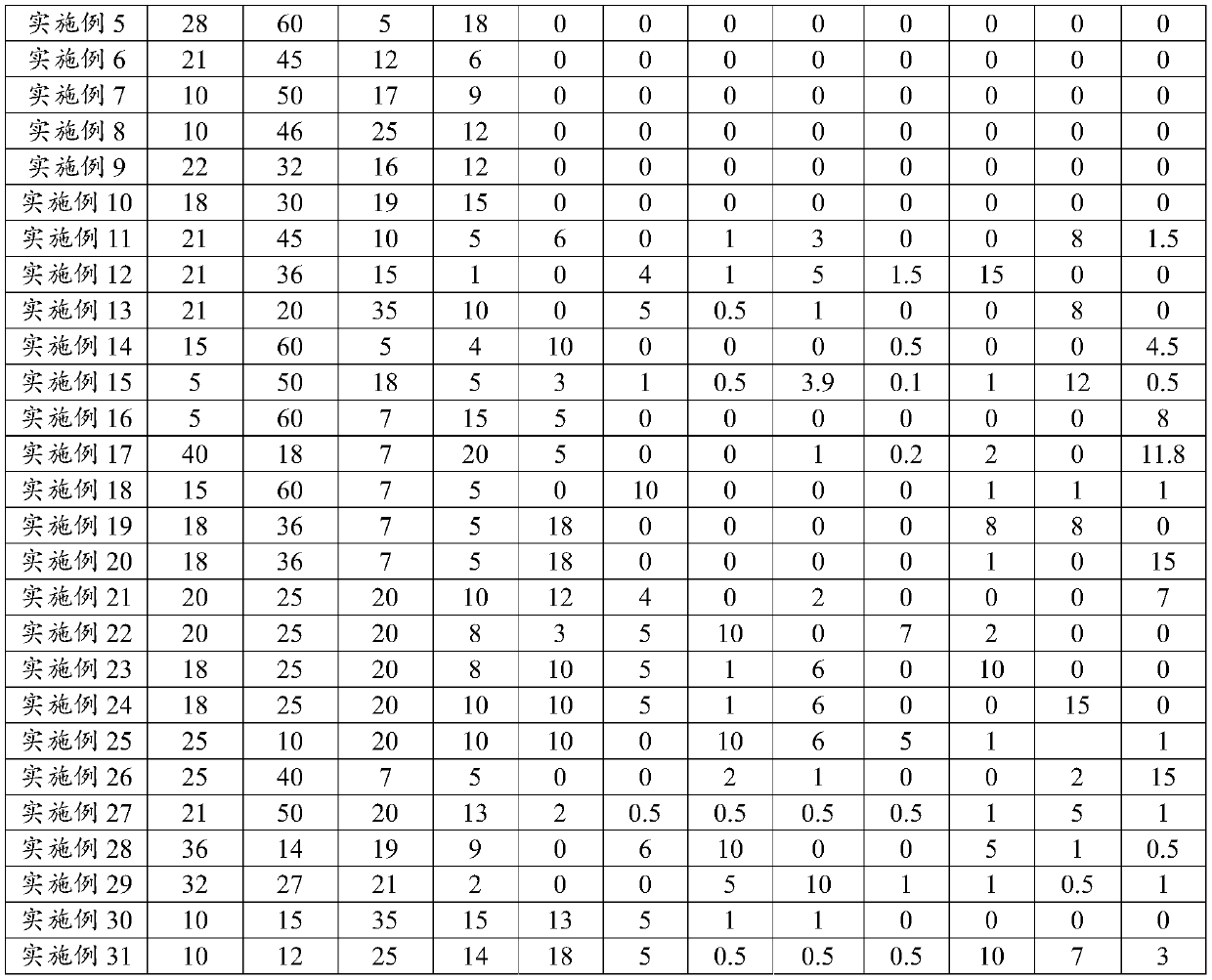

[0033] The present invention sets embodiment 1~31, and the content (in parts by weight) of glass powder in specific embodiment 1~31, as shown in table 1:

[0034] Table 1

[0035]

[0036]

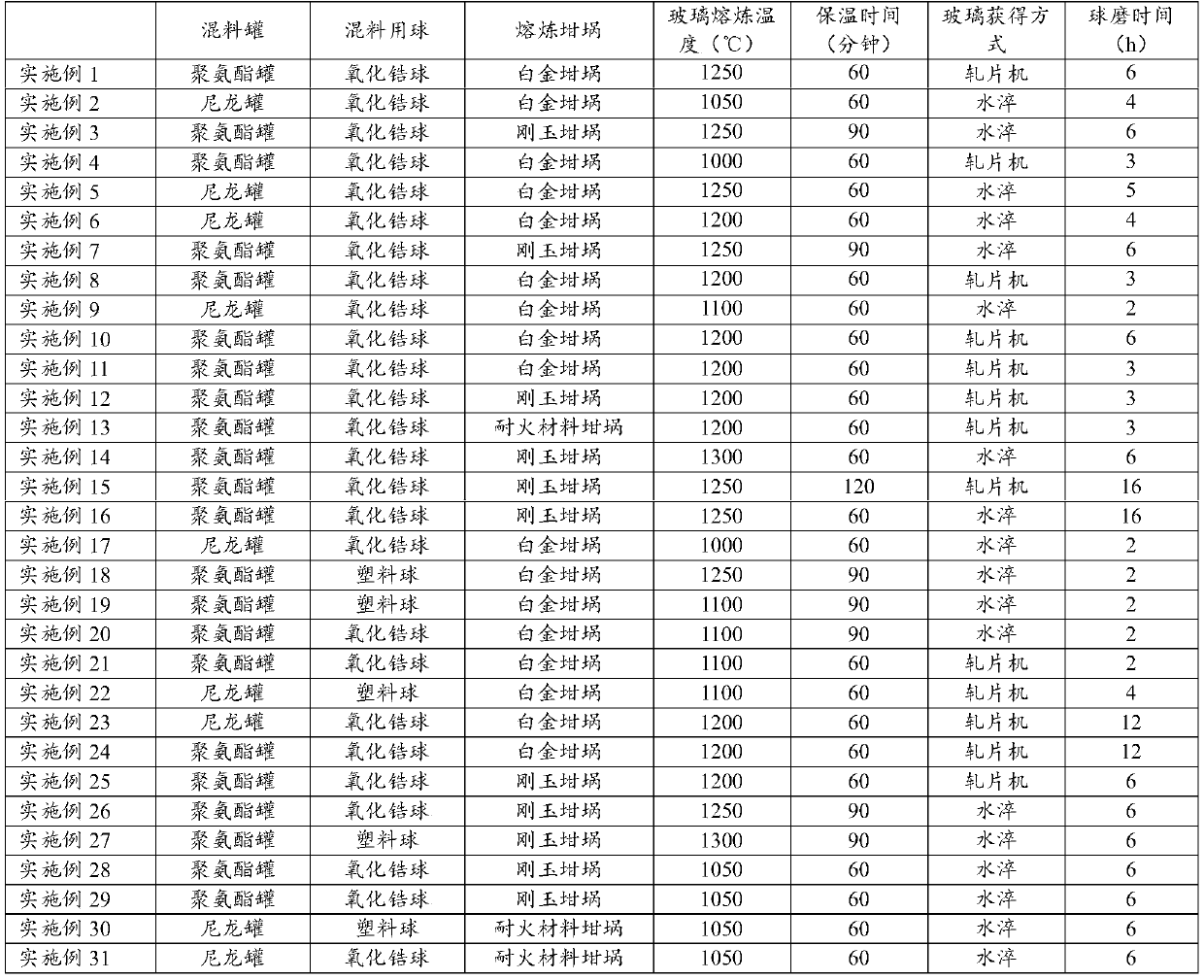

[0037] The preparation method of glass powder in the foregoing embodiment specifically comprises the steps:

[0038] (1) Dosing according to the desired formula composition and mass percentage of lead-free and cadmium-free low-melting glass powder, put the prepared raw materials in polyurethane tank or nylon mixing tank, add plastic or zirconia balls, mix them and place them in platinum In a crucible or in a corundum crucible or a general-purpose refractory crucible, heat to 1000-1300°C and keep warm for 1-2 hours to melt the mixture into glass liquid.

[0039] (2) The molten gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com