Silicon-based composite coating, preparation method and application thereof and aero-engine

An aero-engine and composite coating technology, which is applied in the field of materials, can solve the problems of low temperature resistance of Si coating and cannot meet the requirements, and achieve the effect of improving high temperature viscosity and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

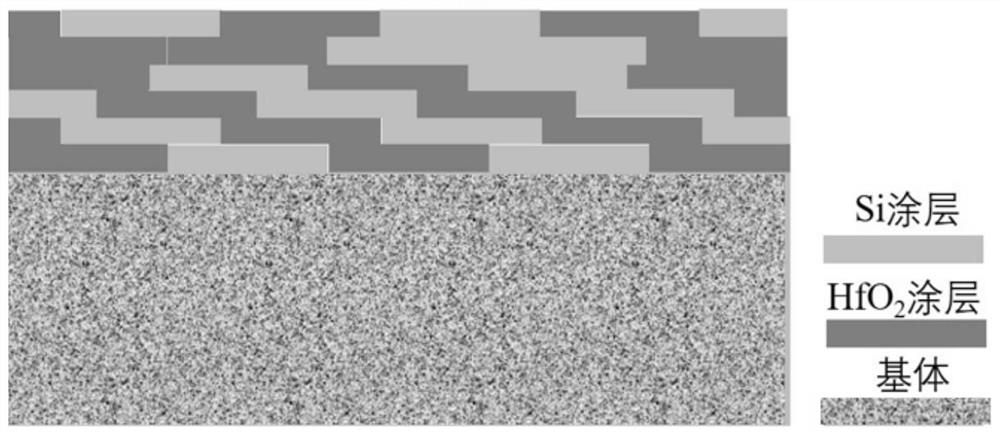

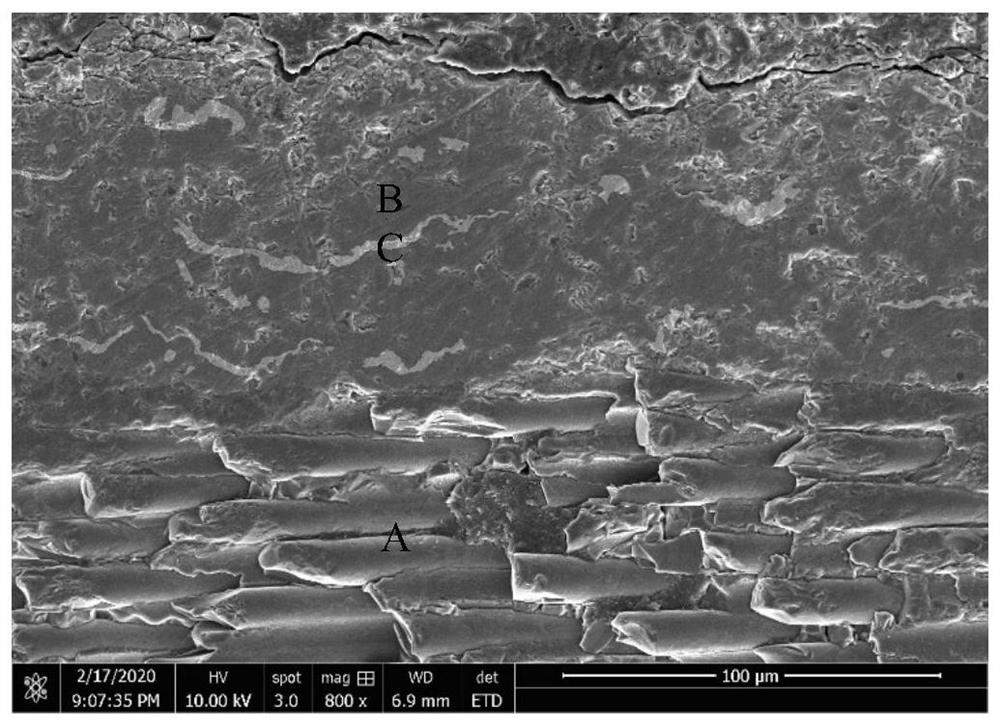

[0064] The Si-HfO prepared by the preparation method provided by this application 2 Silicon based composite coating containing HfSiO 4 High temperature stable phase and form HfO with higher temperature in Si coating 2 High temperature resistant skeleton (such as figure 1 and figure 2 shown). The Si-HfO 2 The porosity of the silicon-based composite coating is about 0.1-0.3%. It is worth noting that the above-mentioned high-temperature stable phase and high temperature in the high-temperature-resistant framework can be understood as being resistant to a temperature of at least 1700°C.

[0065] Preferably, the above-mentioned silicon-based composite coating is Si-HfO 2 / Yb 2 Si 2 o 7 / Rare earth doped ZrO 2 Composite coating, that is, the coating includes Si-HfO arranged sequentially from the inside to the outside 2 Layer, Yb 2 Si 2 o 7 layer and rare earth doped ZrO 2 Floor. In addition, the silicon-based composite coating of the present application can also be ...

Embodiment 1

[0069] The SiC / SiC composite material was ultrasonically cleaned with gasoline and alcohol in sequence, and then the non-sprayed area was pasted and protected with cloth glue, and then the sprayed area was sandblasted with No. 40 corundum grit at 0.5MPa pressure, and cleaned with dry high-pressure air Remove residual grit. Coating Si-HfO on the surface of CMC by atmospheric plasma spraying 2 Composite coating, the process is sprayed with Laval nozzle plasma spray gun, and the parameters of atmospheric plasma spraying are as follows: current is 550A, argon flow rate is 45SLPM, hydrogen flow rate is 8SLPM, Si powder delivery rate is 12g / min, HfO 2 Powder feeding rate is 5g / min, Si raw material and HfO 2The raw material is sent to the center of the flame flow independently and simultaneously by means of double-pipe independent simultaneous powder feeding. The obtained silicon-based composite coating has a porosity of 0.1%, and the coating is kept at 1400° C. for 1000 hours with...

Embodiment 2

[0071] The SiC / SiC composite material was ultrasonically cleaned with gasoline and alcohol in sequence, and then the non-sprayed area was pasted and protected with cloth glue, and then the sprayed area was sandblasted with No. 40 corundum grit at 0.5MPa pressure, and cleaned with dry high-pressure air Remove residual grit. Coating Si-HfO on the surface of CMC by atmospheric plasma spraying 2 Composite coating, the process is sprayed with Laval nozzle plasma spray gun, and the atmospheric plasma spraying parameters are as follows: current is 500A, argon gas flow rate is 40SLPM, hydrogen gas flow rate is 6SLPM, Si powder feeding rate is 8g / min, HfO 2 Powder feeding rate is 5g / min, Si raw material and HfO 2 The raw material is sent to the center of the flame flow independently and simultaneously by means of double-pipe independent simultaneous powder feeding. The porosity of the obtained silicon-based composite coating is 0.1%, and the coating is kept at 1400° C. for 900 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com