High viscosity dibasic acid esters oil and method of producing the same

A high-viscosity, diester technology, which is applied in the field of ester synthetic lubricating oil in synthetic lubricants, can solve the problems of limited viscosity range and low relative molecular weight, and achieve the effects of high relative molecular weight, short reaction time and high viscosity at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

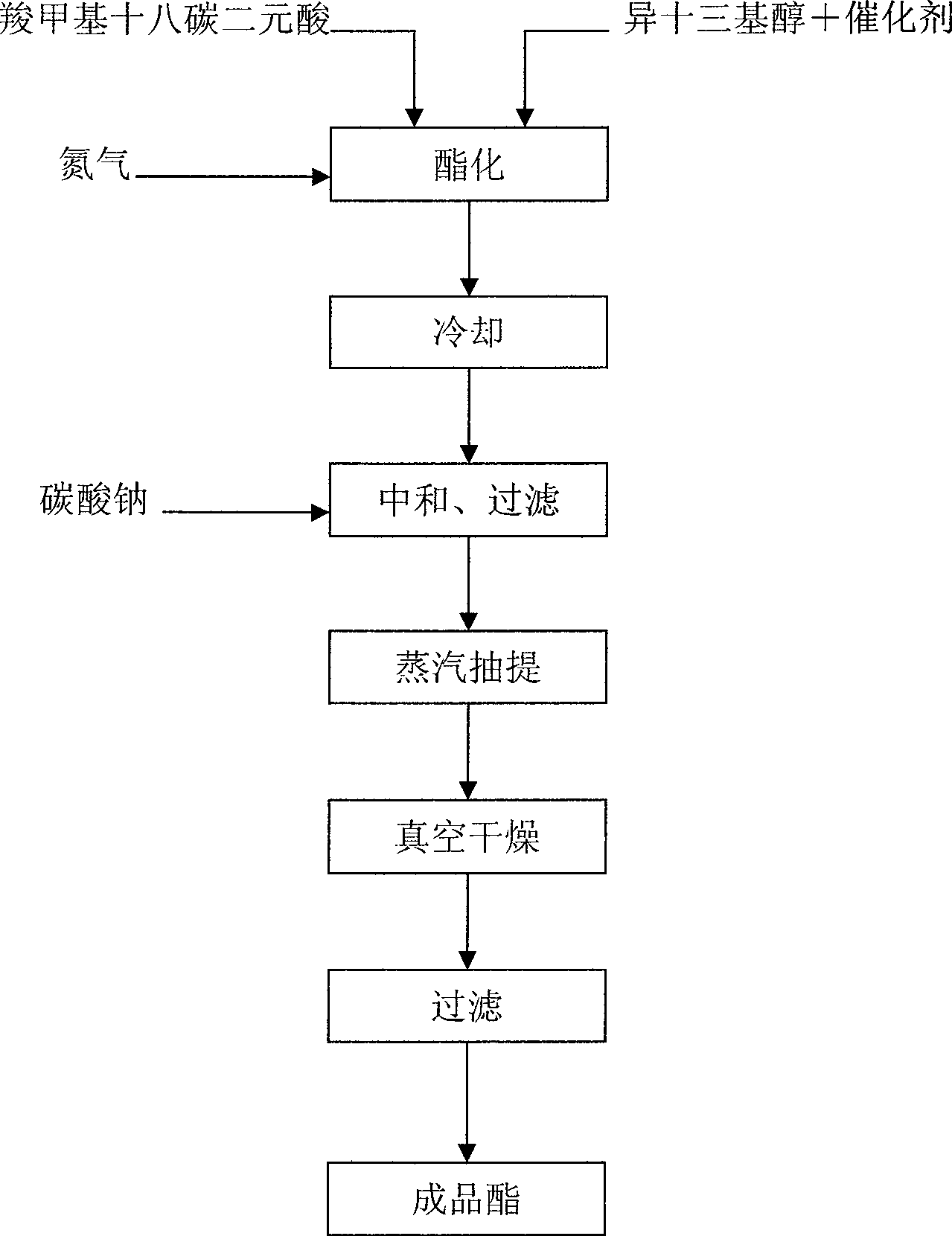

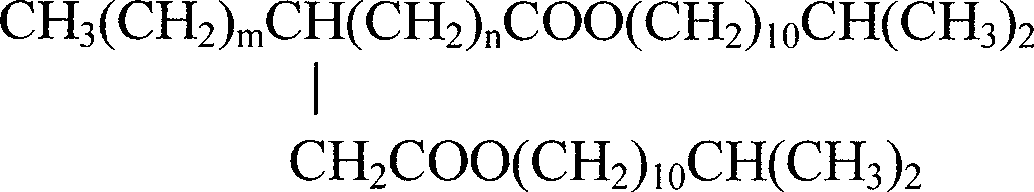

[0025] The present invention uses carboxymethyl octadecanedibasic acid and isotridecanol prepared from methyl oleate as raw materials, under 180-240 DEG C, normal pressure, rare earth solid heterogeneous acid (heteropoly acid HPA and rare earth lanthanum cerium ) is the preparation of isotridecanol carboxymethyl octadecanedioic acid ester by esterification under catalyzer and vacuum condition. (The overall process flow diagram is as follows figure 1 shown).

[0026] Below the concrete content of the present invention, in conjunction with accompanying drawing, be described in further detail as follows:

[0027] The rare earth solid heterogeneous acid catalyst of carboxymethyl octadecanedioic acid 0.3% (mass fraction) is dispersed in the isotridecyl alcohol that the amount of substance is 2.5 times of carboxymethyl octadecanedioic acid, then added to In the carboxymethyl octadecanedibasic acid, the reactor is sealed, filled with nitrogen, heated to 220 ° C, stirring constantl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com