Composite flame retardant, flame-retardant asphalt and preparation method of flame-retardant asphalt

A technology of compounding flame retardant and asphalt, applied in building components, building insulation materials, buildings, etc., can solve the problems of affecting the dispersion and uniformity of montmorillonite, poor compatibility of montmorillonite, and affecting the flame retardant effect, etc. Achieve excellent high temperature stability and low temperature cracking resistance, good thermal oxidation resistance and photooxidative aging resistance, and the effect of reducing the filling amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

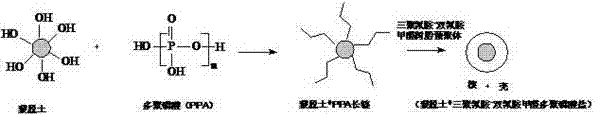

[0039] Preparation of composite flame retardant:

[0040]Among them, the weight content of montmorillonite in montmorillonite is more than 97%, and its particle size is 10 μm. Polyphosphoric acid has a degree of polymerization of 100.

[0041] (1) Under the condition of high-speed stirring (1000-1500r / min), quickly add montmorillonite to polyphosphoric acid ethanol solution (mass concentration: 8%), keep stirring for 20 minutes, and filter to obtain a filter cake.

[0042] (2) Add paraformaldehyde (polymerization degree 30) into ethanol, then adjust the pH value to 8.0 with sodium hydroxide solution, raise the temperature to 70°C, depolymerize and dissolve paraformaldehyde in ethanol, and continue the reaction 80min; then add melamine and dicyandiamide, and react at a temperature of 75°C. After the melamine and dicyandiamide dissolve, continue the reaction for 30min to obtain a melamine-dicyandiamide formaldehyde resin prepolymer with a mass concentration of 65%. weak.

[0...

Embodiment 2

[0054] Preparation of composite flame retardant:

[0055] Among them, the weight content of montmorillonite in montmorillonite is more than 97%, and its particle size is 10 μm. Polyphosphoric acid has a degree of polymerization of 100.

[0056] (1) Under the condition of high-speed stirring (1000-1500r / min), quickly add montmorillonite to polyphosphoric acid ethanol solution (mass concentration: 10%), keep stirring for 20 minutes, and filter to obtain a filter cake.

[0057] (2) Add paraformaldehyde (polymerization degree 50) into ethanol, then adjust the pH value to 9.0 with sodium hydroxide solution, raise the temperature to 70°C, depolymerize and dissolve paraformaldehyde in ethanol, and continue the reaction 60min; then add melamine and dicyandiamide, and react at a temperature of 80°C. After the melamine and dicyandiamide dissolve, continue the reaction for 70min to obtain a melamine-dicyandiamide formaldehyde resin prepolymer with a mass concentration of 75%. weak.

...

Embodiment 3

[0069] Preparation of composite flame retardant:

[0070] Among them, the weight content of montmorillonite in montmorillonite is more than 97%, and its particle size is 10 μm. Polyphosphoric acid has a degree of polymerization of 100.

[0071] (1) Under the condition of high-speed stirring (1000-1500r / min), quickly add montmorillonite to polyphosphoric acid ethanol solution (mass concentration: 12%), keep stirring for 25 minutes, and filter to obtain a filter cake.

[0072] (2) Add paraformaldehyde (polymerization degree 10) into ethanol, then adjust the pH value to 8.0 with sodium hydroxide solution, raise the temperature to 75°C, depolymerize and dissolve paraformaldehyde in ethanol, and continue the reaction Then add melamine and dicyandiamide, and react at a temperature of 78°C. After the melamine and dicyandiamide dissolve, continue the reaction for 20 minutes to obtain a melamine-dicyandiamide formaldehyde resin prepolymer with a mass concentration of 75%. weak.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com