Environment-friendly conduction oil and preparation method thereof

An environmentally friendly heat transfer oil technology, applied in the field of environmentally friendly heat transfer oil and its preparation, can solve the problems of short service life, high use cost, and affecting heat transfer efficiency, so as to reduce the generation and discharge of low boiling substances and prolong the service life , The effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

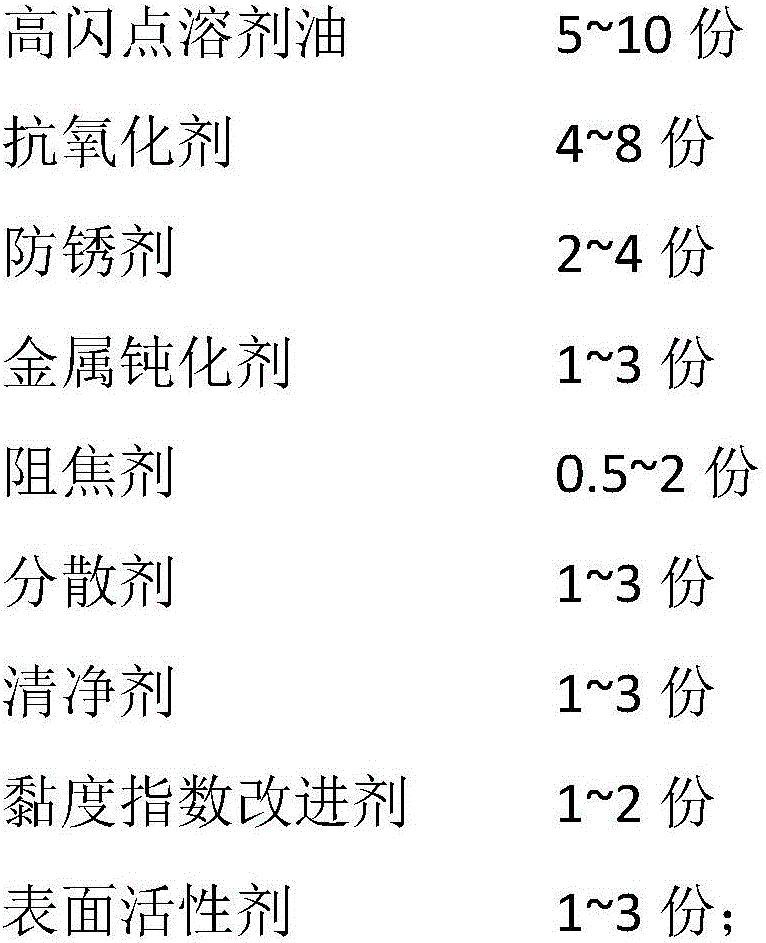

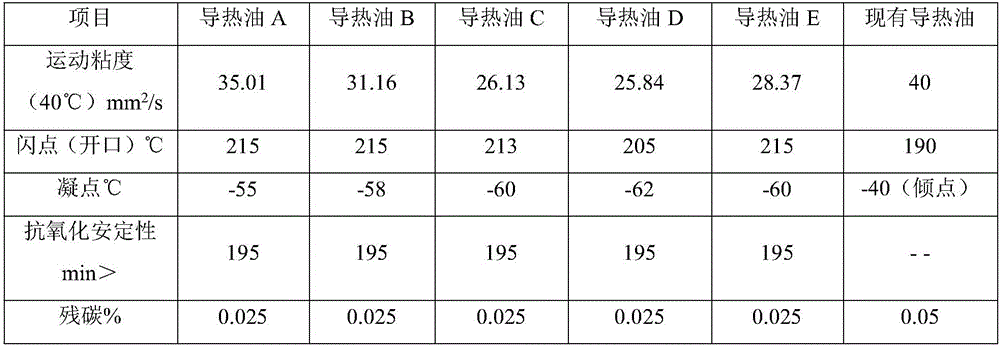

[0027] An environment-friendly heat transfer oil, comprising: 85 parts of composite base oil, 5 parts of high flash point solvent oil, 4 parts of antioxidant, 2 parts of antirust agent, 1 part of metal deactivator, 0.5 part of coking inhibitor , 1 part of dispersant, 1 part of detergent, 1 part of viscosity index improver, and 1 part of surfactant; the method for preparing the above-mentioned heat transfer oil comprises the following steps: firstly mix antioxidant, Rust inhibitors, metal deactivators, coke inhibitors, surfactants, dispersants, detergents and viscosity index improvers are dissolved in high flash point solvent oil; then the mixture obtained above is added to the composite base oil in proportion , to obtain heat transfer oil A.

Embodiment 2

[0029] An environment-friendly heat transfer oil, comprising: 86 parts of composite base oil, 6 parts of high flash point solvent oil, 5 parts of antioxidant, 2 parts of antirust agent, 1 part of metal deactivator, 0.5 part of coking inhibitor , 1 part of dispersant, 1 part of detergent, 1 part of viscosity index improver, and 1 part of surfactant; the method for preparing the above-mentioned heat transfer oil comprises the following steps: firstly mix antioxidant, Rust inhibitors, metal deactivators, coke inhibitors, surfactants, dispersants, detergents and viscosity index improvers are dissolved in high flash point solvent oil; then the mixture obtained above is added to the composite base oil in proportion , to obtain heat transfer oil B.

Embodiment 3

[0031] An environment-friendly heat transfer oil, comprising: 87 parts of composite base oil, 7 parts of high flash point solvent oil, 6 parts of antioxidant, 3 parts of antirust agent, 2 parts of metal deactivator, 1 part of coking inhibitor in parts by mass , 2 parts of dispersants, 2 parts of detergents, 1.5 parts of viscosity index improvers, and 1.5 parts of surfactants; the method for preparing the above-mentioned heat transfer oil comprises the following steps: firstly mix antioxidant, Rust inhibitors, metal deactivators, coke inhibitors, surfactants, dispersants, detergents and viscosity index improvers are dissolved in high flash point solvent oil; then the mixture obtained above is added to the composite base oil in proportion , to obtain heat transfer oil C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com