Preparation method for pomegranate flavored yoghurt powder

A technology of yogurt powder and flavor, which is applied in the field of preparation of pomegranate-flavored yogurt powder, can solve the problems of difficulty in ensuring the supply of yogurt in the market, cumbersome yogurt production procedures, and large labor consumption, etc., and achieves suitable for large-scale production, low cost, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A preparation method of pomegranate-flavored yogurt powder, comprising the following steps:

[0049] (1) Mix pomegranate juice and yogurt at a mass ratio of 1:5, then add sugar and CMC and mix to obtain pomegranate-flavored yogurt, wherein sugar accounts for 8.0% of the total mass of pomegranate-flavored yogurt, and CMC accounts for 0.06% of the total mass of pomegranate-flavored yogurt %;

[0050] (2) Dilute the pomegranate-flavored yogurt obtained in step (1) with water to a solid content of 20%, then add carrageenan and mix to form a mixture, and the amount of carrageenan added is the total mass of the diluted pomegranate-flavored yogurt 0.02% of;

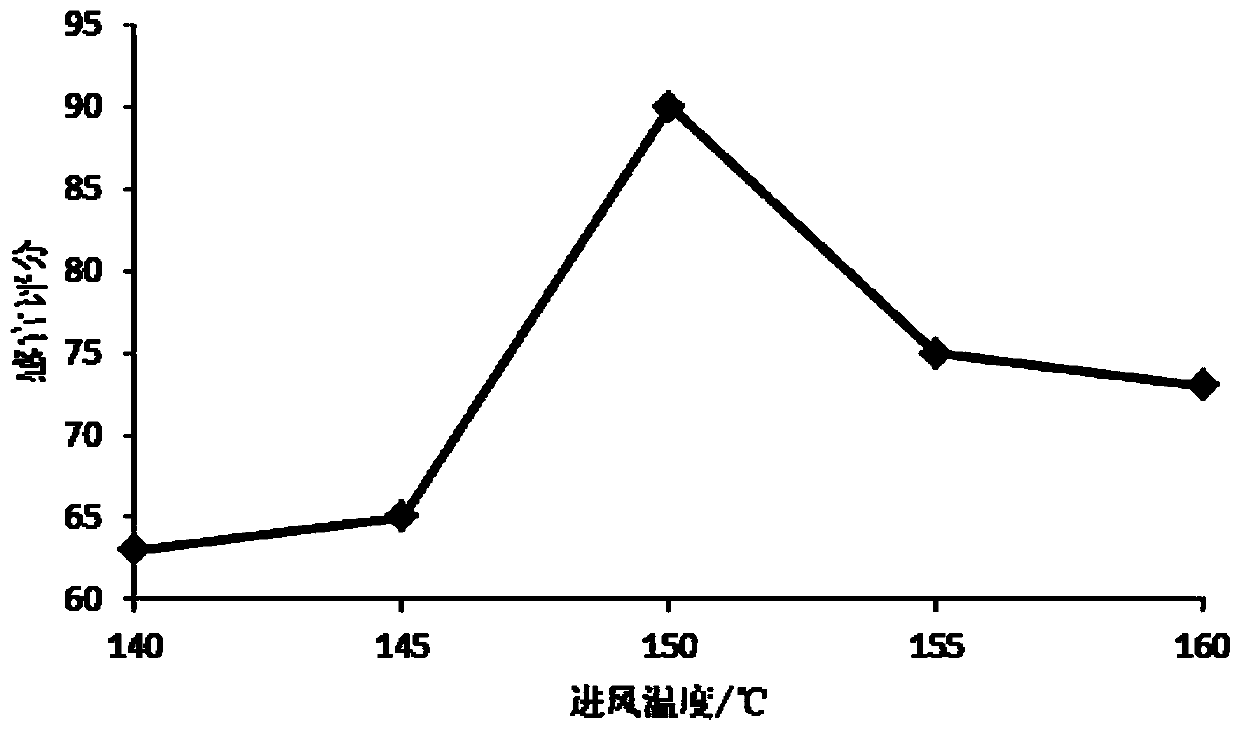

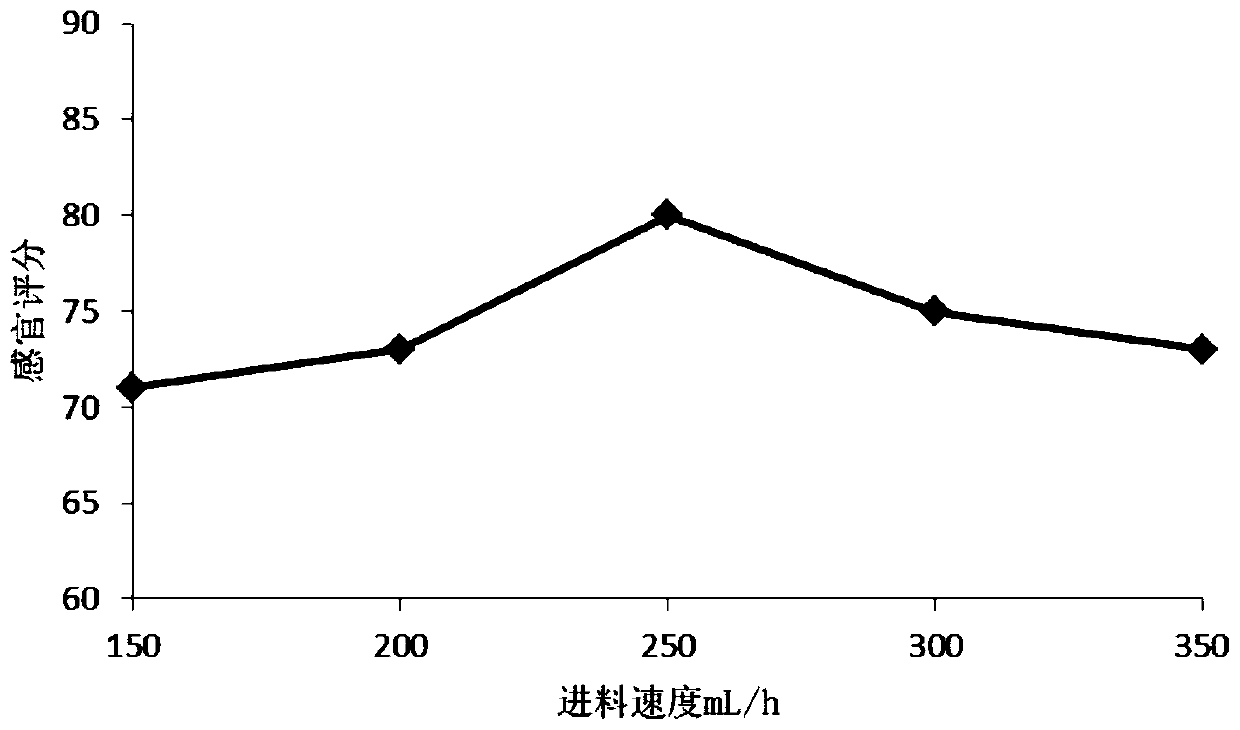

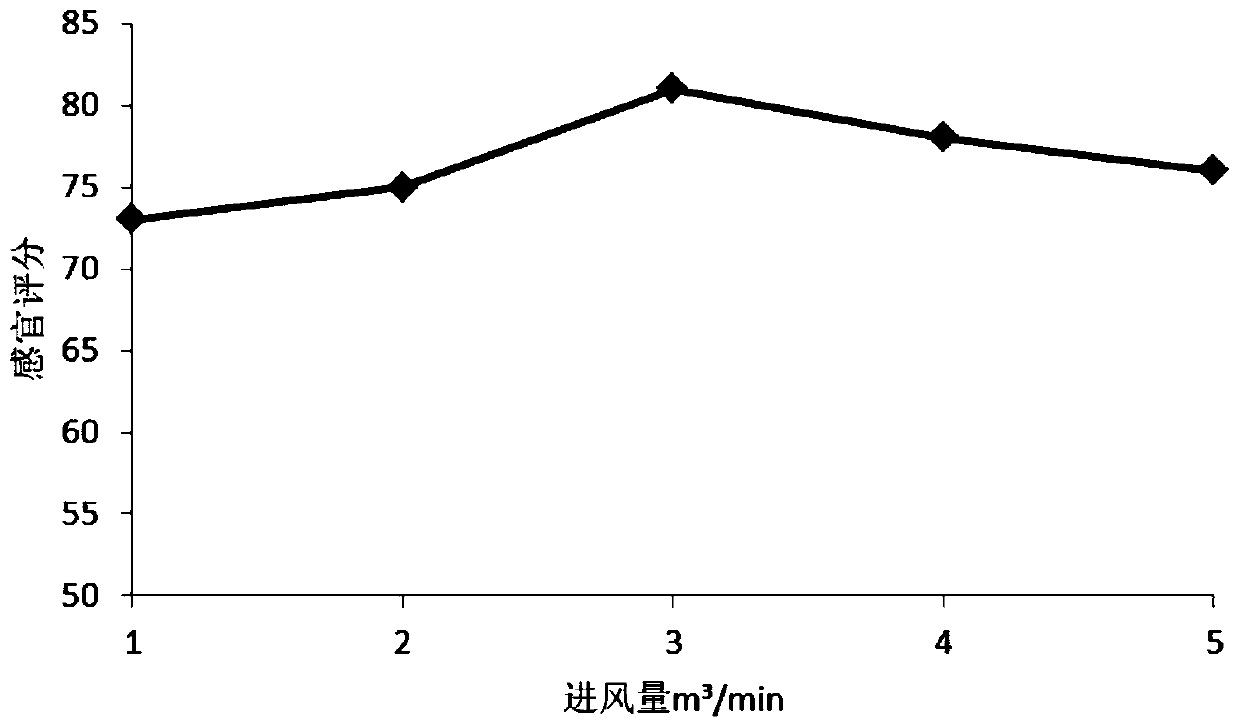

[0051] (3) Put the mixture obtained in step (2) into the feed port of the spray dryer, and carry out the spray drying operation to obtain the crude product, wherein the outlet temperature of the spray dryer is set to 70°C, the air inlet temperature is 150°C, and the feed rate 250mL / h, air intake 3m 3 / min;

[0052] (4...

Embodiment 2

[0054] A preparation method of pomegranate-flavored yogurt powder, comprising the following steps:

[0055] (1) Mix pomegranate juice and yogurt at a mass ratio of 1:5, then add sugar and CMC and mix to obtain pomegranate-flavored yogurt, wherein sugar accounts for 8.0% of the total mass of pomegranate-flavored yogurt, and CMC accounts for 0.06% of the total mass of pomegranate-flavored yogurt %;

[0056] (2) Dilute the pomegranate-flavored yogurt obtained in step (1) with water to a solid content of 20%, then add carrageenan and mix to form a mixture, and the amount of carrageenan added is the total mass of the diluted pomegranate-flavored yogurt 0.02% of;

[0057] (3) Put the mixture obtained in step (2) into the feed port of the spray dryer, and carry out the spray drying operation to obtain the crude product, wherein the outlet temperature of the spray dryer is set to 70°C, the air inlet temperature is 150°C, and the feed rate 250mL / h, air intake 1m 3 / min;

[0058] (4...

Embodiment 3

[0060] A preparation method of pomegranate-flavored yogurt powder, comprising the following steps:

[0061] (1) Mix pomegranate juice and yogurt at a mass ratio of 1:5, then add sugar and CMC and mix to obtain pomegranate-flavored yogurt, wherein sugar accounts for 8.0% of the total mass of pomegranate-flavored yogurt, and CMC accounts for 0.06% of the total mass of pomegranate-flavored yogurt %;

[0062] (2) Dilute the pomegranate-flavored yogurt obtained in step (1) with water to a solid content of 20%, then add carrageenan and mix to form a mixture, and the amount of carrageenan added is the total mass of the diluted pomegranate-flavored yogurt 0.02% of;

[0063] (3) Put the mixture obtained in step (2) into the feed port of the spray dryer, and carry out the spray drying operation to obtain the crude product, wherein the outlet temperature of the spray dryer is set to 70°C, the air inlet temperature is 150°C, and the feed rate 250mL / h, air intake 5m 3 / min;

[0064] (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com