Wall cloth glutinous adhesive powder, and preparation method and application thereof

A technology of wall covering and wax glue, applied in the directions of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of easy generation of air bubbles during the blending process, lack of mildew resistance and waterproofness, and affecting the bonding effect, etc. To achieve the effect of improving the anti-mildew effect, good construction performance technical support, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

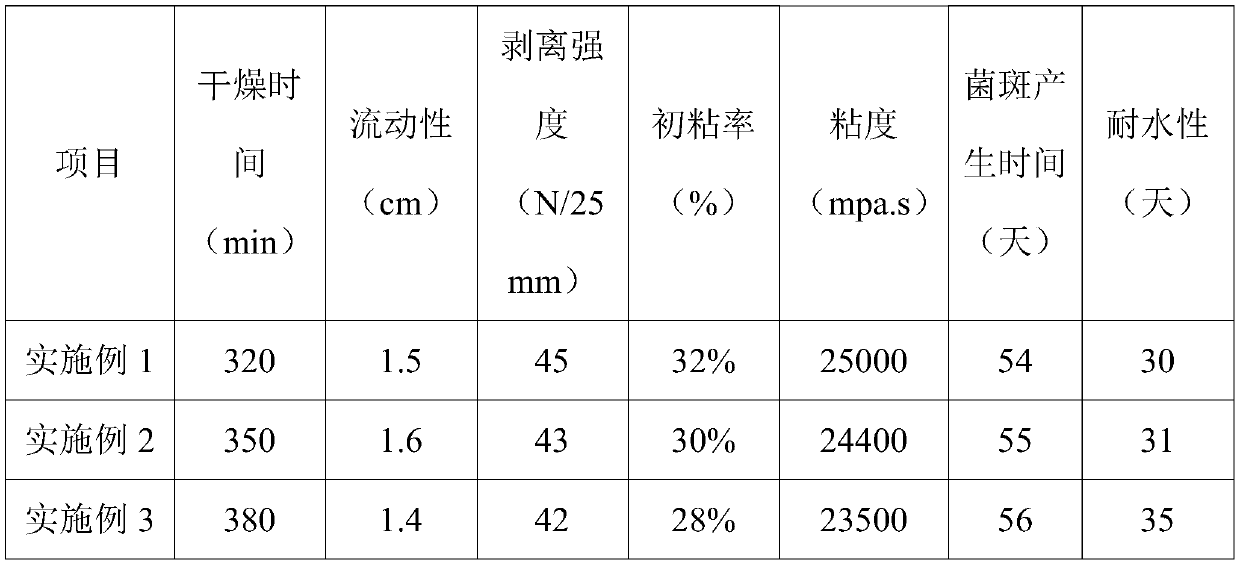

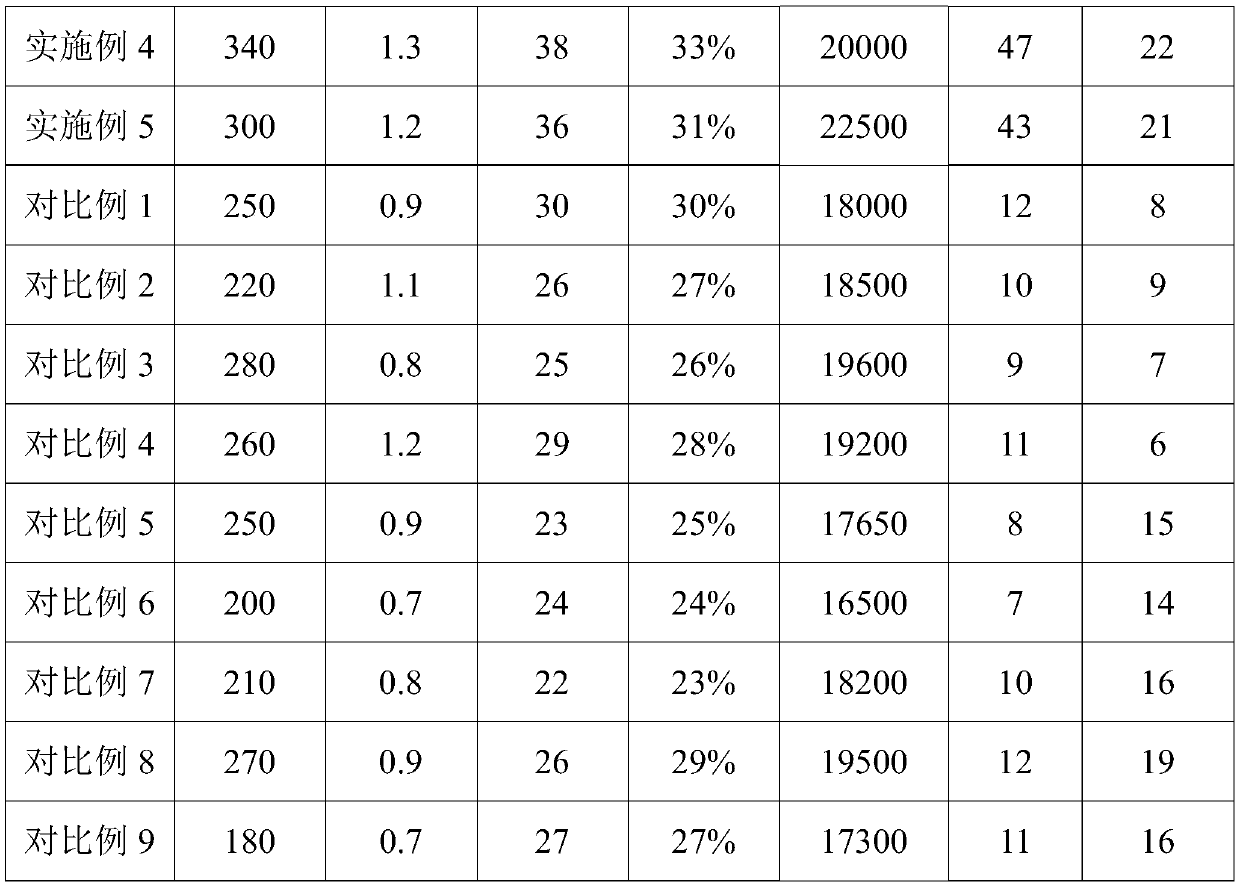

Examples

Embodiment 1

[0053] This embodiment provides a kind of wall covering waxy glue powder, the preparation raw material of described wall covering waxy glue powder comprises the following components by weight part: 100 parts of waxy cornstarch (the branch chain content of waxy cornstarch accounts for 100% of waxy cornstarch). 98% of the total molecular weight of corn starch), 2.5 parts of 32% sodium hydroxide aqueous solution, 0.15 parts of sodium trimetaphosphate, 3 parts of hydrogen peroxide (volume ratio concentration is 15%), 35 parts of sodium polyacrylate, 10 parts of polyethylene ammonia, 0.03 parts of fumaric acid and 80 parts of water.

[0054] The preparation method of the wall cloth glutinous rubber powder of the present embodiment may further comprise the steps:

[0055] (1) Starch pretreatment: add 32% potassium hydroxide aqueous solution and 50 parts of deionized water to the waxy cornstarch of formula quantity, obtain starch salt solution;

[0056] (2) Cross-linked oxidized sta...

Embodiment 2

[0061] This embodiment provides a kind of wall covering waxy glue powder, the preparation raw material of described wall covering waxy glue powder comprises the following components by weight: 90 parts of waxy cornstarch (the branched chain content of waxy cornstarch accounts for 99% of the total molecular mass of corn starch), 2.5 parts of 32% sodium hydroxide aqueous solution, 0.1 part of sodium trimetaphosphate, 1 part of hydrogen peroxide (10% by volume), 30 parts of sodium polyacrylate, 5 parts of polyethylene ammonia, Kasong 0.01 part and water 60 parts.

[0062] The preparation method of the wall cloth glutinous rubber powder of the present embodiment may further comprise the steps:

[0063] (1) Starch pretreatment: add 32% aqueous sodium hydroxide solution and 30 parts of deionized water to the waxy corn starch of formula quantity, obtain starch salt solution;

[0064] (2) Cross-linked oxidized starch: adding sodium trimetaphosphate and hydrogen peroxide to the starch...

Embodiment 3

[0069] This embodiment provides a kind of wall covering waxy glue powder, the preparation raw material of described wall covering waxy glue powder comprises the following components in parts by weight: 110 parts of waxy cornstarch (the branched chain content of waxy cornstarch accounts for 98% of the total molecular weight of corn starch), 5 parts of 32% sodium hydroxide aqueous solution, 0.2 part of sodium trimetaphosphate, 5 parts of hydrogen peroxide (volume ratio concentration is 25%), 40 parts of sodium polyacrylate, 15 parts of polyethylene ammonia, 0.02 parts of sodium lactate and 80 parts of water.

[0070] The preparation method of the wall cloth glutinous rubber powder of the present embodiment may further comprise the steps:

[0071] (1) starch pretreatment: add 32wt% sodium hydroxide aqueous solution and 40 parts of deionized water to the waxy cornstarch of formula quantity, obtain starch salt solution;

[0072] (2) Cross-linked oxidized starch: adding sodium trim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com