Ganoderma spore oil microcapsule powder and preparing method and application thereof

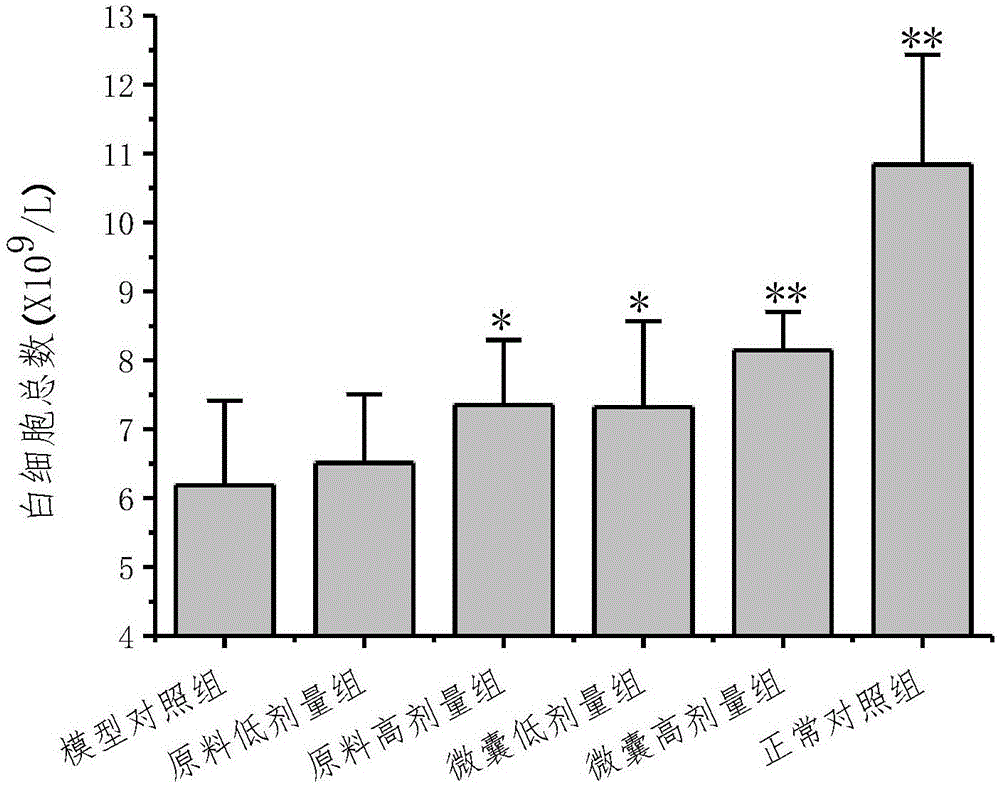

A technology of spore oil microcapsule powder and ganoderma spore oil, which is applied in microcapsules, capsule delivery, pharmaceutical formulations, etc., can solve the problem of inability to effectively promote the bioavailability of ganoderma spore oil, increase in acid value and peroxide value, and disintegration Unqualified and other problems, to achieve the effect of improving bioavailability, increasing specific surface area, and enhancing immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

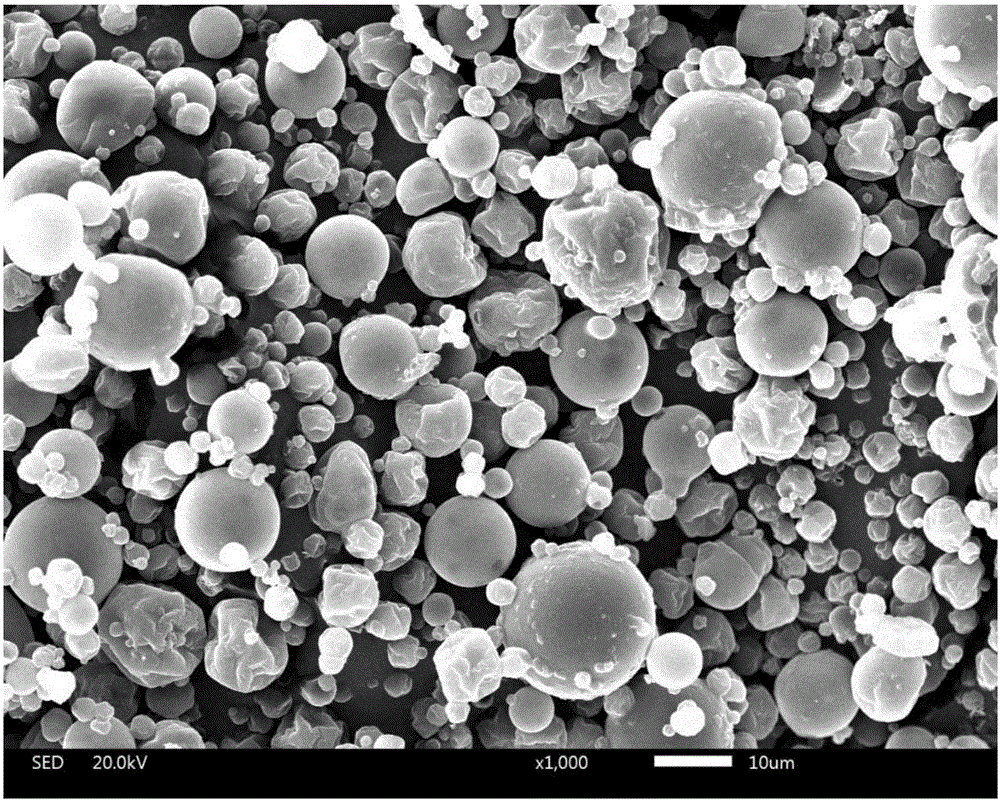

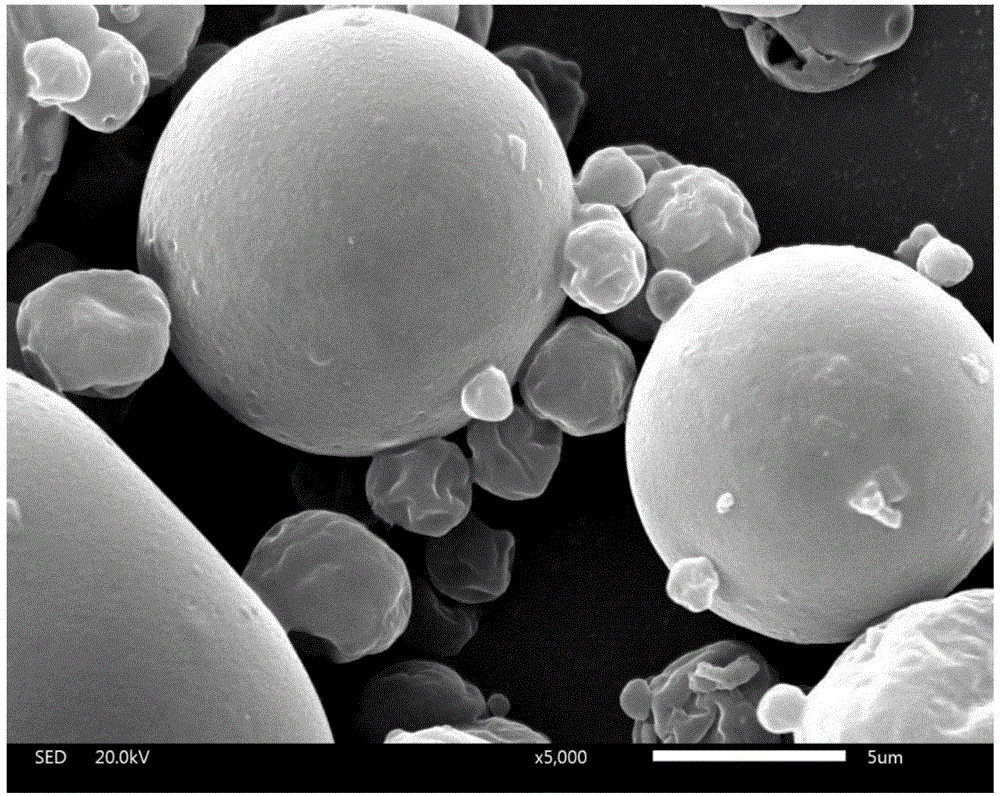

[0029] Embodiment 1: Preparation of Ganoderma lucidum spore oil microcapsule powder of the present invention

[0030] 1. Composition

[0031] Wall material: Ganoderma lucidum spore oil = 3:2, starch sodium octenyl succinate in wall material: maltodextrin = 1:1

[0032] 2. Preparation method

[0033] adding the wall material into ultrapure water, heating and stirring at 80°C to dissolve, and obtaining an aqueous solution of the wall material; wherein the mass concentration of the composite wall material aqueous solution is 30%;

[0034] Add Ganoderma lucidum spore oil to the above-mentioned wall material aqueous solution, and shear 2min at a high speed at a speed of 16000r / min to obtain the primary emulsion; wherein, the mass ratio of the composite wall material to the Ganoderma lucidum spore oil is 3:2; the obtained primary emulsion With high pressure 300Bar and temperature 50℃, homogenize twice to obtain a uniform and stable final emulsion;

[0035] The above homogenized f...

Embodiment 2

[0038] Embodiment 2: preparation Ganoderma lucidum spore oil microcapsule powder of the present invention

[0039] 1. Composition

[0040] Wall material: Ganoderma lucidum spore oil = 3:2, starch sodium octenyl succinate in wall material: maltodextrin = 1:0.5

[0041] 2. Preparation method

[0042] adding the wall material into ultrapure water, heating and stirring at 70°C to dissolve, and obtaining an aqueous wall material solution; wherein the mass concentration of the wall material aqueous solution is 40%;

[0043] Add Ganoderma lucidum spore oil in the above-mentioned wall material aqueous solution, shear 2min at a high speed with the speed of 16000r / min, obtain primary emulsion; Wherein, the mass ratio of described wall material and Ganoderma lucidum spore oil is 3:2; High pressure 300Bar, temperature 50°C, homogenize twice to obtain a uniform and stable final emulsion;

[0044] The above homogenized final emulsion was spray-dried to obtain Ganoderma lucidum spore oil ...

Embodiment 3

[0047] Embodiment 3: preparation Ganoderma lucidum spore oil microcapsule powder of the present invention

[0048] 1. Composition

[0049] Wall material: Ganoderma lucidum spore oil = 3:2, starch sodium octenyl succinate in wall material: maltodextrin = 1:2

[0050] 2. Preparation method

[0051] adding the wall material into ultrapure water, heating and stirring at 90°C to dissolve, and obtaining an aqueous solution of the wall material; wherein the mass concentration of the composite wall material aqueous solution is 50%;

[0052] Add Ganoderma lucidum spore oil to the above-mentioned wall material aqueous solution, and shear 2min at a high speed at a speed of 16000r / min to obtain the primary emulsion; wherein, the mass ratio of the composite wall material to the Ganoderma lucidum spore oil is 3:2; the obtained primary emulsion Homogenize once with high pressure 300Bar and temperature 50°C to obtain a uniform and stable final emulsion;

[0053] The above homogenized final...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com