Protective film for electronic screen

A technology of protective film and screen, applied in the direction of film/sheet release liner, polymer adhesive additive, film/sheet adhesive, etc. Product quality and other issues, to achieve the effect of good viscosity and reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

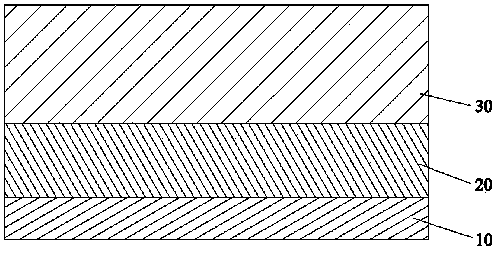

[0010] see figure 1 , the electronic screen protective film of the present invention comprises a substrate layer 30, an adhesive layer 20 and a bottom layer 10, and the adhesive layer 30 is made of the following raw materials in parts by weight: 15-20 parts of acrylic copolymer; 10-15 parts of joint agent; 25-35 parts of ethyl acetate; 12-16 parts of toluene; 6-10 parts of rosin resin; 5-10 parts of glycerin; 4-8 parts of curing agent; 3-5 parts of sodium silicate; 10-18 parts of high-temperature filler, the substrate layer is PET film with a thickness of 25 μm, and the bottom layer is double-sided silicon release paper with a thickness of 30 μm.

[0011] The formula of the invention is reasonable, and has good viscosity, adhesion, retention and rolling ball initial tack. The lamination temperature of this product is best used at a temperature above 10°C. After lamination,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com