Ceramic-polished-tile-powder-modified asphalt made from industrial waste residue and preparation method of modified asphalt

A ceramic polishing brick and ceramic polishing technology, which is applied to building components, building insulation materials, buildings, etc., to achieve the effects of high efficiency, effective utilization, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

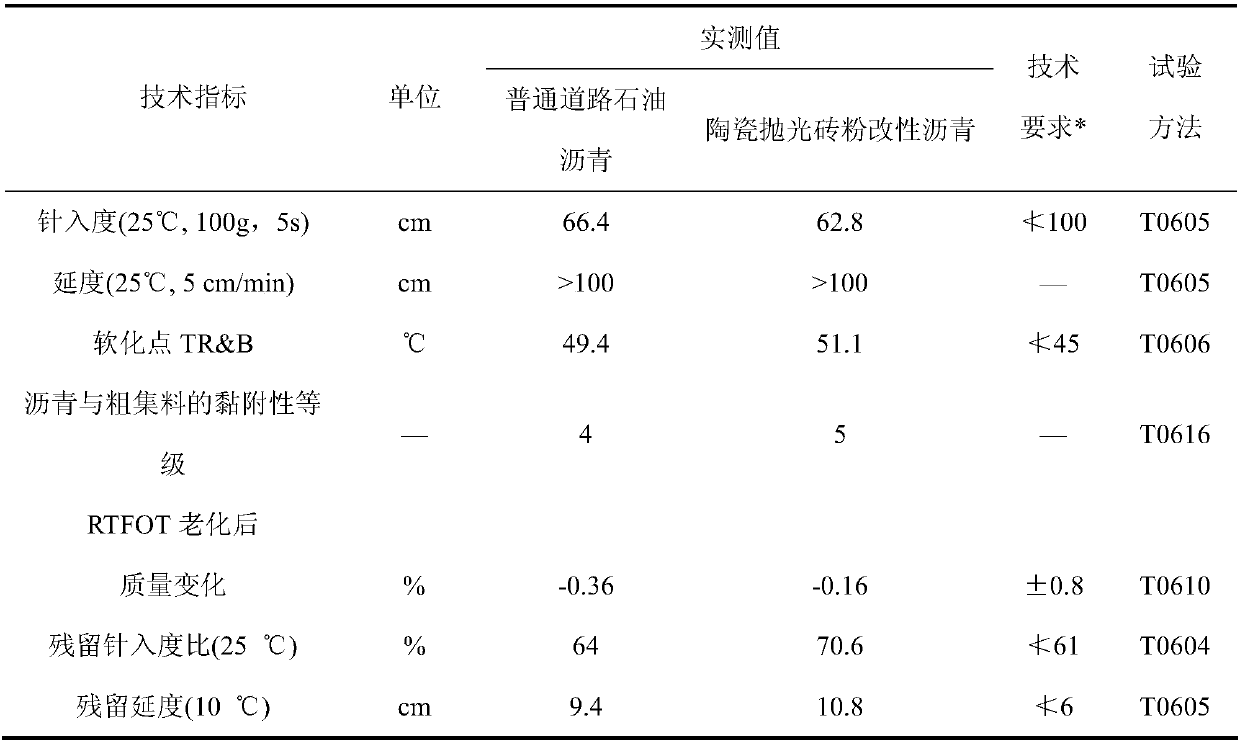

Embodiment 1

[0035] (1) Material preparation: After dehydration and air-drying, the ceramic polishing waste and waste powder from ceramic enterprises are sent to a ball mill to be ground into powder, and then sent to a special ash storage tank for standby.

[0036] (2) Ingredients: Surface-modified ceramic polished brick powder Ingredients: The mass ratio of ceramic polished brick powder to silane coupling agent KH-550 solution with a mass concentration of 1% is 1:1; The mass percentages are as follows: surface-modified ceramic polished brick powder 5%, ordinary road petroleum asphalt 95%.

[0037] (3) Prepare deionized ethanol solution: mix deionized water and dehydrated ethanol, and adjust the pH value of the mixed solution with glacial acetic acid, wherein the ratio of each raw material is: m (deionized water): m (dehydrated ethanol)= (1~4): (6~9), pH=3~5, the mixed solution is obtained;

[0038] (4) Preparation of silane coupling agent KH-550 solution: Weigh a certain amount of silane...

Embodiment 2

[0042] Example 2: surface-modified ceramic polished brick powder ingredients: the mass ratio of ceramic polished brick powder and silane coupling agent KH-550 solution with a mass concentration of 2% is 1:1; the proportion of modified asphalt raw materials accounts for the mass The percentages are as follows: surface modified ceramic polished brick powder 8%, ordinary road petroleum asphalt 92%. Others are the same as in Example 1. The main technical indicators of the above-mentioned modified asphalt are as follows: penetration 63.4, ductility at 25°C > 100, softening point 51.4, residual penetration ratio 72.6, residual ductility 11.2, and the adhesion level to coarse aggregate is 5 .

Embodiment 3

[0043] Example 3: Surface-modified ceramic polished brick powder ingredients: the mass ratio of ceramic polished brick powder to 3% silane coupling agent KH-550 solution is 1:2; the ratio of modified asphalt raw materials accounts for the mass The percentages are as follows: surface modified ceramic polished brick powder 10%, ordinary road petroleum asphalt 90%. Others are the same as in Example 1. The main technical indicators of the above-mentioned modified asphalt are as follows: penetration 62, ductility at 25°C > 100, softening point 52.0, residual penetration ratio 70.3, residual ductility 10.4, and adhesion to coarse aggregate grade 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com