Pressure sensitive adhesive tape for high-temperature resistant masking and preparation method thereof

A pressure-sensitive adhesive tape, high temperature resistant technology, used in adhesives, natural rubber coatings, natural rubber adhesives, etc., can solve the problems of inconvenience in the manufacturing process, achieve good adhesion characteristics, improved peel strength and cohesive strength, relative molecular weight. The effect of mass increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

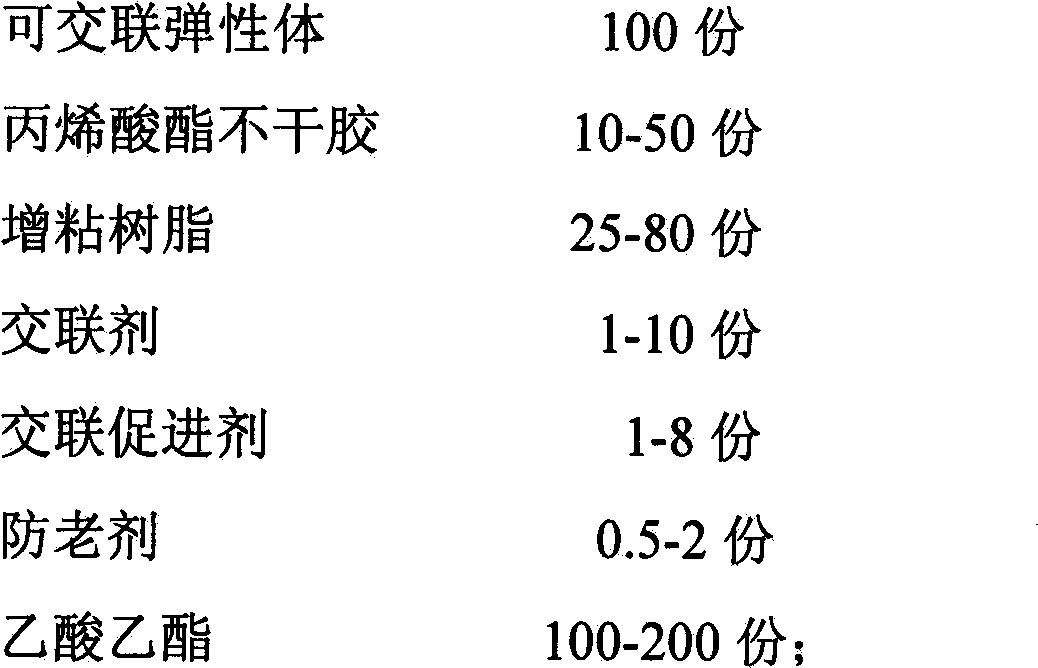

Method used

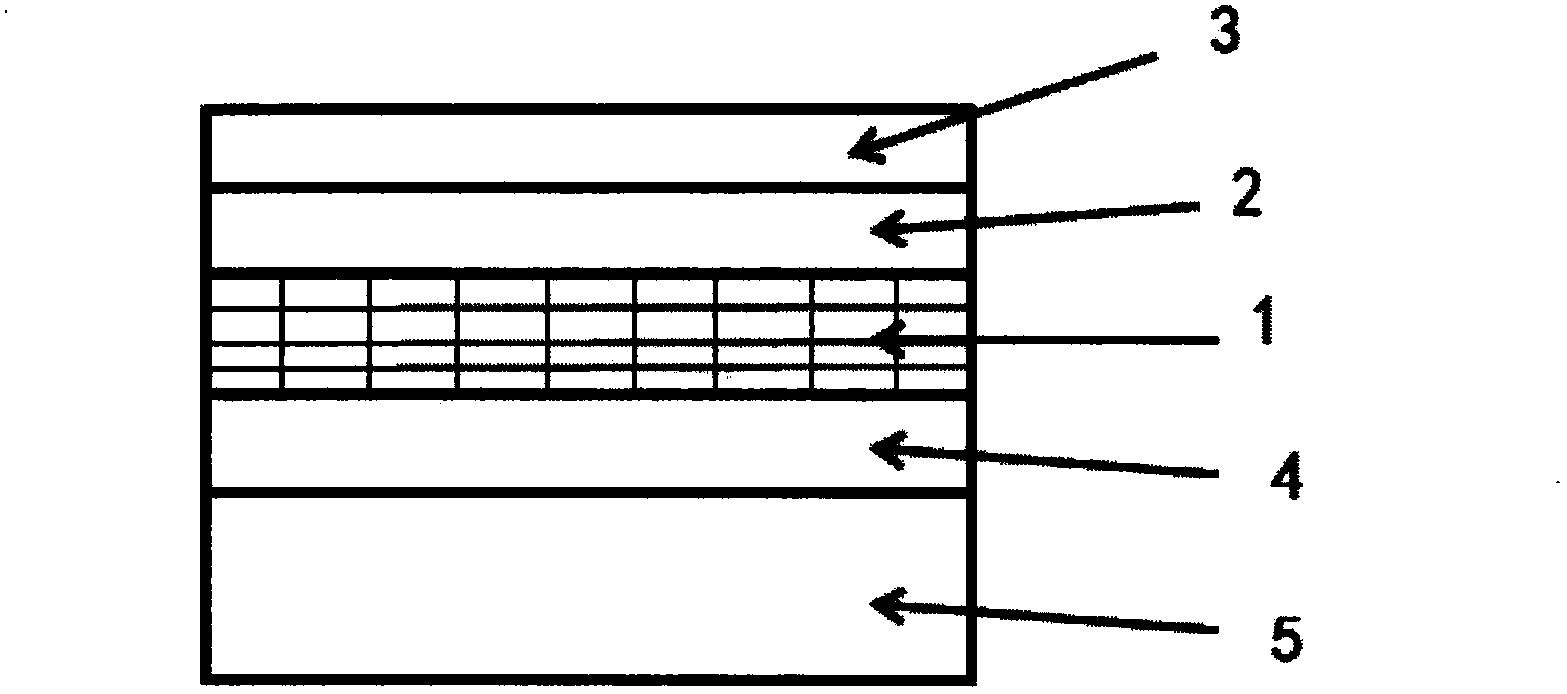

Image

Examples

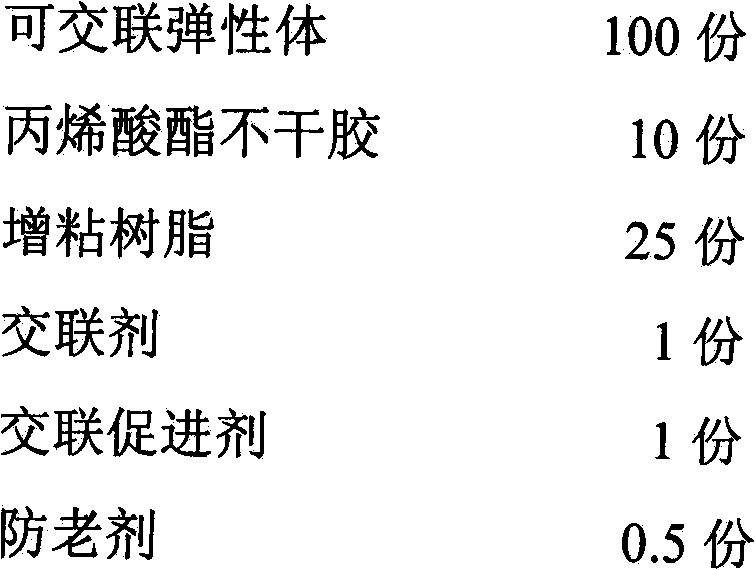

Embodiment 1

[0041] Add 10 parts of acrylic ester self-adhesive (solid content is 50%) in 100 parts (parts by weight, the same below) of natural rubber latex (solid content is 60%), add 25 parts of rosin ester tackifying resin after stirring evenly, 1 part Crosslinking agent improved N-methylolacrylamide, 1 part of crosslinking accelerator zinc dibutyldithiocarbamate, 0.5 part of rubber antioxidant N-phenyl-N'-cyclohexyl-p-phenylenediamine, Add 100 parts of solvent ethyl acetate, stir for 5 minutes, place the adhesive composition in a heat-collecting magnetic stirrer, and stir for 20 minutes with a stirring bar at 50°C, so that the components are fully soluble, and the curing amount of the adhesive composition is controlled 20%, take it out for use, that is, to prepare an adhesive.

[0042] Add 10 parts of acrylate self-adhesive (50% of solid content) to 100 parts of natural rubber latex (60% of solid content), then add 150 parts of solvent ethyl acetate, stir well until the solid content ...

Embodiment 2

[0046]Add 30 parts of acrylate self-adhesive (solid content is 50%) to 100 parts of natural rubber latex (solid content is 60%), after stirring evenly, add 45 parts of rosin ester tackifying resin, 5 parts of crosslinking agent modified N- Methylol acrylamide, 5 parts of zinc dibutyl dithiocarbamate, 1 part of rubber antioxidant N-phenyl-N'-cyclohexyl-p-phenylenediamine, 150 parts of solvent ethyl acetate , after stirring for 5 minutes, place the adhesive composition in a heat-collecting magnetic stirrer, and stir for 30 minutes with a stirring bar at 60°C, so that the components are fully soluble in each other, and the curing amount of the adhesive composition is controlled to 30%, take it out for use , which is formulated into an adhesive.

[0047] Add 30 parts of acrylate self-adhesive (50% solid content) to 100 parts of natural rubber latex (60% solid content), then add 200 parts ethyl acetate as a solvent, and stir until the solid content is 25%. That is, the preparation...

Embodiment 3

[0051] Add 50 parts of acrylate self-adhesive (solid content is 50%) to 100 parts of natural rubber latex (solid content is 60%), after stirring evenly, add 60 parts of rosin ester tackifying resin, 10 parts of crosslinking agent modified N- Methylol acrylamide, 8 parts of zinc dibutyldithiocarbamate, 8 parts of crosslinking accelerator, 2 parts of rubber antioxidant N-phenyl-N'-cyclohexyl-p-phenylenediamine, 200 parts of solvent ethyl acetate , after stirring for 5 minutes, place the adhesive composition in a heat-collecting magnetic stirrer, stir for 40 minutes with a stirring bar at a temperature of 80°C, so that the components are fully soluble in each other, and the curing amount of the adhesive composition is controlled to 50%, take it out for use , which is formulated into an adhesive.

[0052] Add 50 parts of acrylate self-adhesive (solid content is 50%) to 100 parts of natural rubber latex (solid content is 60%), then add 200 parts of solvent ethyl acetate, stir until...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com