Ultra-low carbon high-purity industrial pure iron and manufacturing method thereof

A technology of industrial pure iron and manufacturing method, which is applied in the field of metallurgy and can solve the problems of low performance of maraging steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

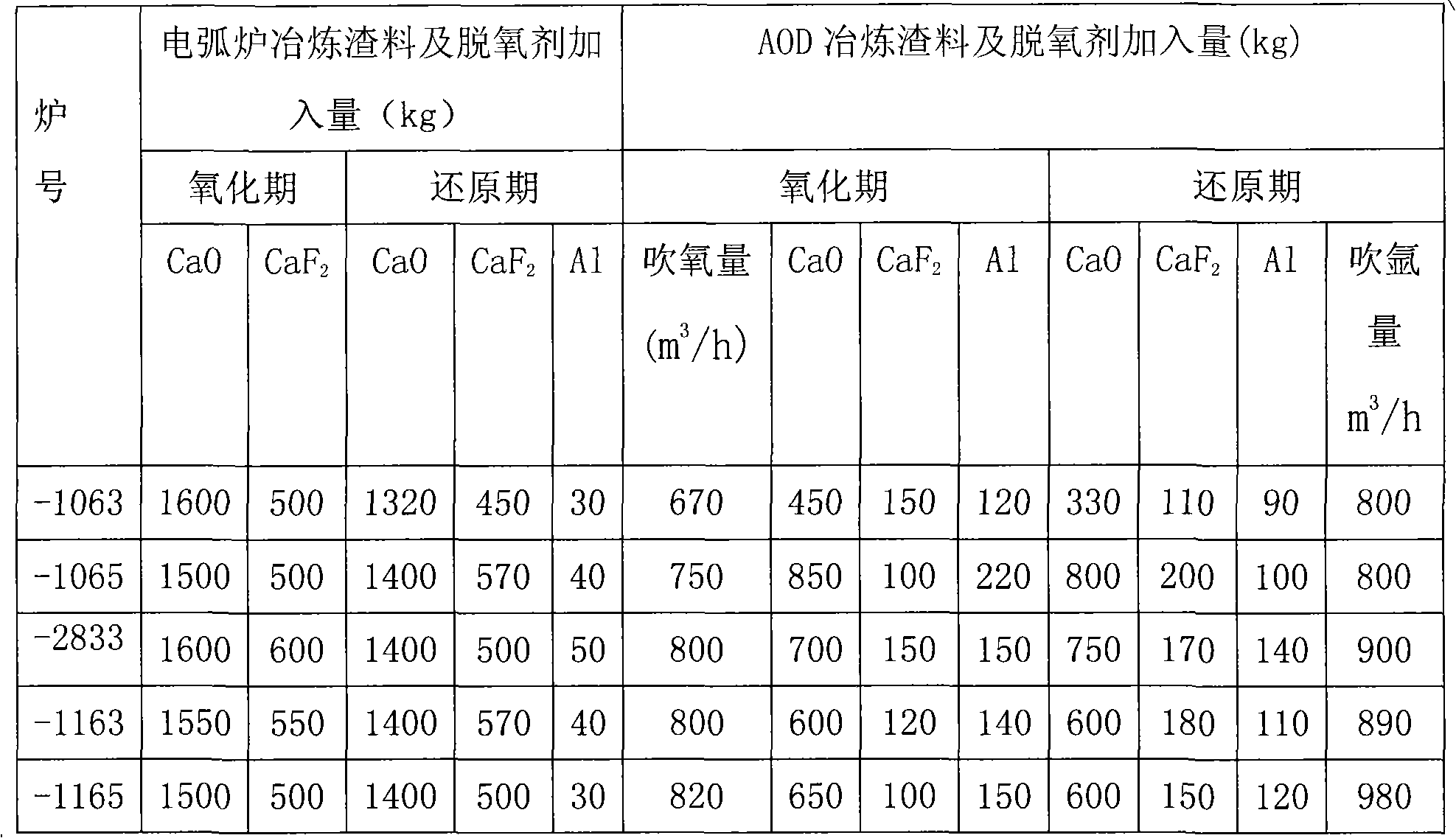

[0034] (1) EAF furnace:

[0035] After the charge is fully melted, add lime in 4 to 6 batches, blow oxygen for oxidation treatment, the temperature is 1560 °C, phosphorus is less than 0.003%, and slag removal is 100%; reduction: add lime in three batches of 15-20Kg / ton. Batch, fluorite 5-8Kg / ton.batch, aluminum 1~2.5kg / ton; when sulfur≤0.010% slag removal 100%, add the third batch of CaO15~20kg / ton, CaF 2 1~2kg / ton and aluminum 1~2.5kg / ton, new slag is produced and tapped, the tapping temperature is 1620℃, and it enters the AOD furnace;

[0036] (2) AOD furnace:

[0037] After blending with steel, add two batches of CaO20~40kg / ton, CaF 2 2~7kg / ton, aluminum 5~10kg / ton, blowing oxygen (argon) and its flow rate is: O 2 : 800m 3 / h, Ar200m 3 The amount of oxygen blowing per hour is about 800 cubic meters. When the carbon reaches below 0.008%, the reduction is carried out, and the temperature is 1720°C.

[0038] Reduction, removal of oxidation slag, pre-deoxidation: add CaO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com