Magnesium-calcium-titanium-carbon brick and preparation method thereof

A magnesium-calcium-titanium-carbon brick and titanium dioxide technology, which is applied in the field of refractory materials for metallurgical refining ladles (refining furnaces), can solve the problems of short storage time, easy hydration, large change rate of reburning line, and poor thermal shock resistance. Achieve excellent anti-hydration performance, small change in reburning line, and improve anti-hydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A magnesia-calcium-titanium-carbon brick of the present invention is composed of the following raw materials in proportion by weight percentage as follows: 74% of sintered dolomite sand, wherein: 30% of particle size greater than 3-5mm, 28% of greater than 1-3mm, 0.088-1mm 16%; fused magnesia 14%, particle size ≤ 0.088mm; expanded graphite 2%; asphalt powder 2%; anhydrous resin 3%; , Metal Si powder 0.5%, B 4 C powder 0.5%); rutile industrial titanium dioxide 3%.

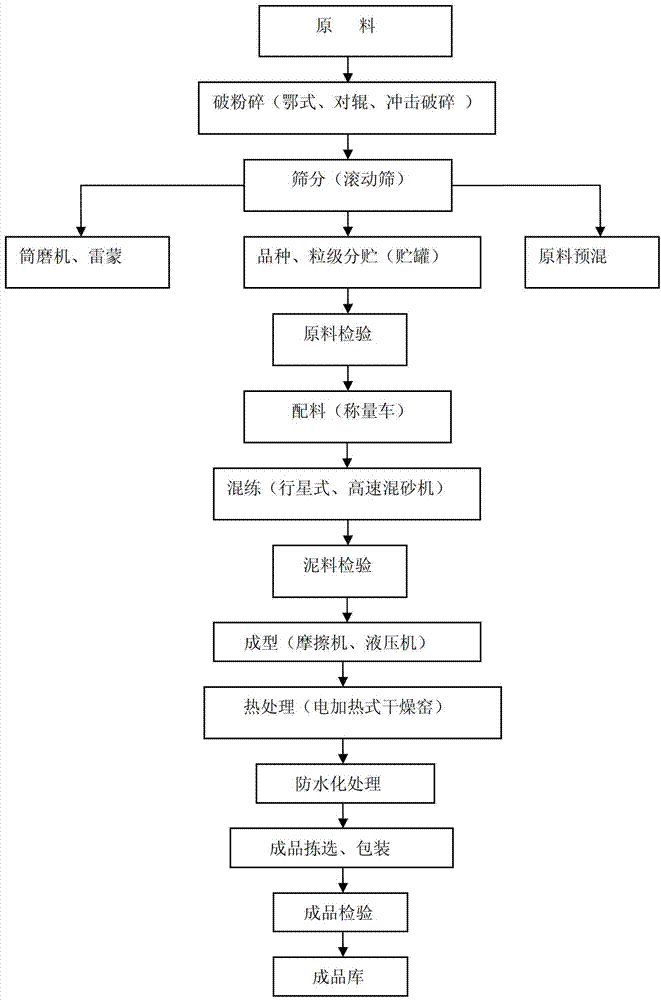

[0051] See figure 1 , is the flow chart of the preparation method of the magnesium-calcium-titanium-carbon brick of the present invention, including mixing, compression molding, heat treatment, water-repellent treatment and vacuum packaging, and its specific operation steps are as follows:

[0052] 1) Crushing sintered dolomite sand and fused magnesia, the crushing equipment can choose jaw crusher, double roller crusher or impact crusher, and screen with rolling sieve. 3mm, 0.088~1mm three particle sizes a...

Embodiment 2

[0059] A magnesia-calcium-titanium-carbon brick of the present invention is composed of the following raw materials according to weight percentage: 64% of sintered dolomite sand, wherein: 28% of particle size greater than 3-5mm, 25% of greater than 1-3mm, 0.088-1mm 11%; fused magnesia 21%, particle size ≤ 0.088mm; graphite 4% (of which: flake graphite 2%, expanded graphite 2%); asphalt powder 2.5%; anhydrous resin 4%; urotropine 0.5%; Antioxidant 2% (of which: aluminum-magnesium alloy powder 1.5%, B 4 C powder 0.5%); rutile industrial titanium dioxide 2%. The preparation method is the same as in Example 1.

[0060] The product of Example 2 is used on the ladle slag line of the 80-ton LF furnace of domestic B steel plant, and the life of a single slag line is more than 90 times.

Embodiment 3

[0062] A magnesia-calcium-titanium-carbon brick of the present invention is composed of the following raw materials in proportion by weight percentage: 51% of sintered dolomite sand, of which: 21% of particle size greater than 3-5mm, 20% of greater than 1-3mm, 0.088-1mm 10%; fused magnesia 36%, of which 5% is larger than 3-5mm, 6% is larger than 1-3mm, 7% is larger than 0.088-1mm, 18% is ≤0.088mm; graphite 5% (of which: flake graphite 3%, expanded graphite 2%); asphalt powder 1%; anhydrous resin 3.5%; urotropine 0.5%; antioxidant 2% (of which: aluminum-magnesium alloy powder 1.5%, B 4 C powder 0.5%); rutile industrial titanium dioxide 1%.

[0063] The preparation method of the magnesia-calcium-titanium-carbon brick includes mixing materials, press molding, heat treatment, waterproofing treatment and vacuum packaging, and its specific operation steps are as follows:

[0064] 1) Crushing sintered dolomite sand and fused magnesia, the crushing equipment can choose jaw crusher, d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com