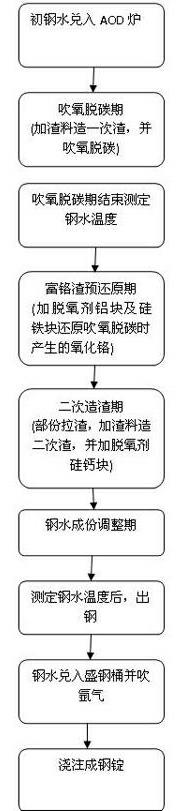

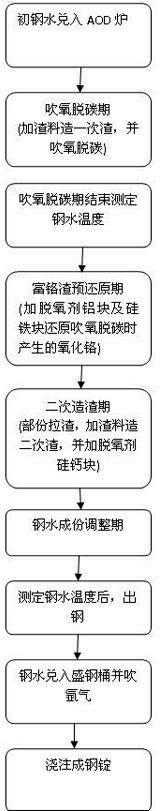

Desulfurization and deoxidation process for smelting stainless steel in small-capacity AOD (Argon Oxygen Decarburization) furnace by double-slag process

A double-slag method and small-capacity technology, which is applied in oxygen process, desulfurization of stainless steel smelted by double-slag method in small-capacity AOD furnace, and smelting process of small-capacity AOD furnace, can solve the problems of large heat consumption and influence on molten steel temperature, and achieve The effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Smelting UNS S32205, the capacity of AOD furnace is 3.5 tons.

[0059] After the initial molten steel is mixed into the AOD furnace, it enters the oxygen blowing decarburization period, and slag is added for slagging, and oxygen blowing decarburization is completed. When the ferrosilicon block reduces the chromium oxide produced during oxygen blowing decarburization, when the chromium-rich slag is pre-reduced, the temperature of the molten steel is controlled at 1750°C; The amount of lime added per ton of molten steel is 20 kg / ton of molten steel. The lime composition (mass percentage) and characteristics are: C: 0.2%, S: 0.025%, CaO: 93%, burning loss rate: 0.72%, activity (in hydrochloric acid titration When) is 350, the addition amount of silicon-calcium block per ton of molten steel deoxidizer is 5 kg / ton of molten steel, the composition of silicon-calcium block is (mass percentage): Si: 55%, Ca: 20%, the particle size of lime and silicon-calcium block 20-30mm. Th...

Embodiment 2

[0064] Smelting UNS S31803, AOD furnace capacity 5 tons.

[0065]After the initial molten steel is mixed into the AOD furnace, it enters the oxygen blowing decarburization period, and the slag is added for slagging and oxygen blowing decarburization. And the chromium oxide produced during oxygen blowing and decarburization of ferrosilicon block. When the reduction of chromium-rich slag is completed, the temperature of molten steel is controlled at 1770°C; The amount of lime added per ton of molten steel is 50 kg / ton of molten steel. The lime composition (mass percentage) and characteristics are: C: 0.17%, S: 0.022%, CaO: 92%, burning loss rate: 0.75%, activity (in hydrochloric acid Titration time) is 360, the addition amount of per ton of molten steel deoxidizer silicon calcium block is 7 kg / ton of molten steel, the composition of silicon calcium block is (mass percentage): Si: 57%, Ca: 16%, lime and silicon calcium block particles The degree is 20-30mm. The amount of fluori...

Embodiment 3

[0070] Smelting UNS S32750, the capacity of AOD furnace is 3.5 tons.

[0071] After the initial molten steel is mixed into the AOD furnace, it enters the oxygen blowing decarburization period, and the slag is added for slagging and oxygen blowing decarburization. And the chromium oxide produced during oxygen blowing and decarburization of ferrosilicon block. When the reduction of chromium-rich slag is completed, the temperature of molten steel is controlled at 1762°C; The amount of lime added per ton of molten steel is 35 kg / ton of molten steel. The lime composition (mass percentage) and characteristics are: C: 0.18%, S: 0.021%, CaO: 94%, burning loss rate: 0.73%, activity (in hydrochloric acid Titration time) is 365, and the addition amount of per ton of molten steel deoxidizer silicon-calcium block is 5.4 kg / ton of molten steel, and the composition of silicon-calcium block is (mass percentage): Si: 58%, Ca: 17%, particles of lime and silicon-calcium block The degree is 20-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com