Material with high wear resistance

一种耐磨性、工具钢的技术,应用在莱氏体工具钢的制作领域,能够解决限制硬度潜能等问题,达到断面收缩率提高、高回火硬度值的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

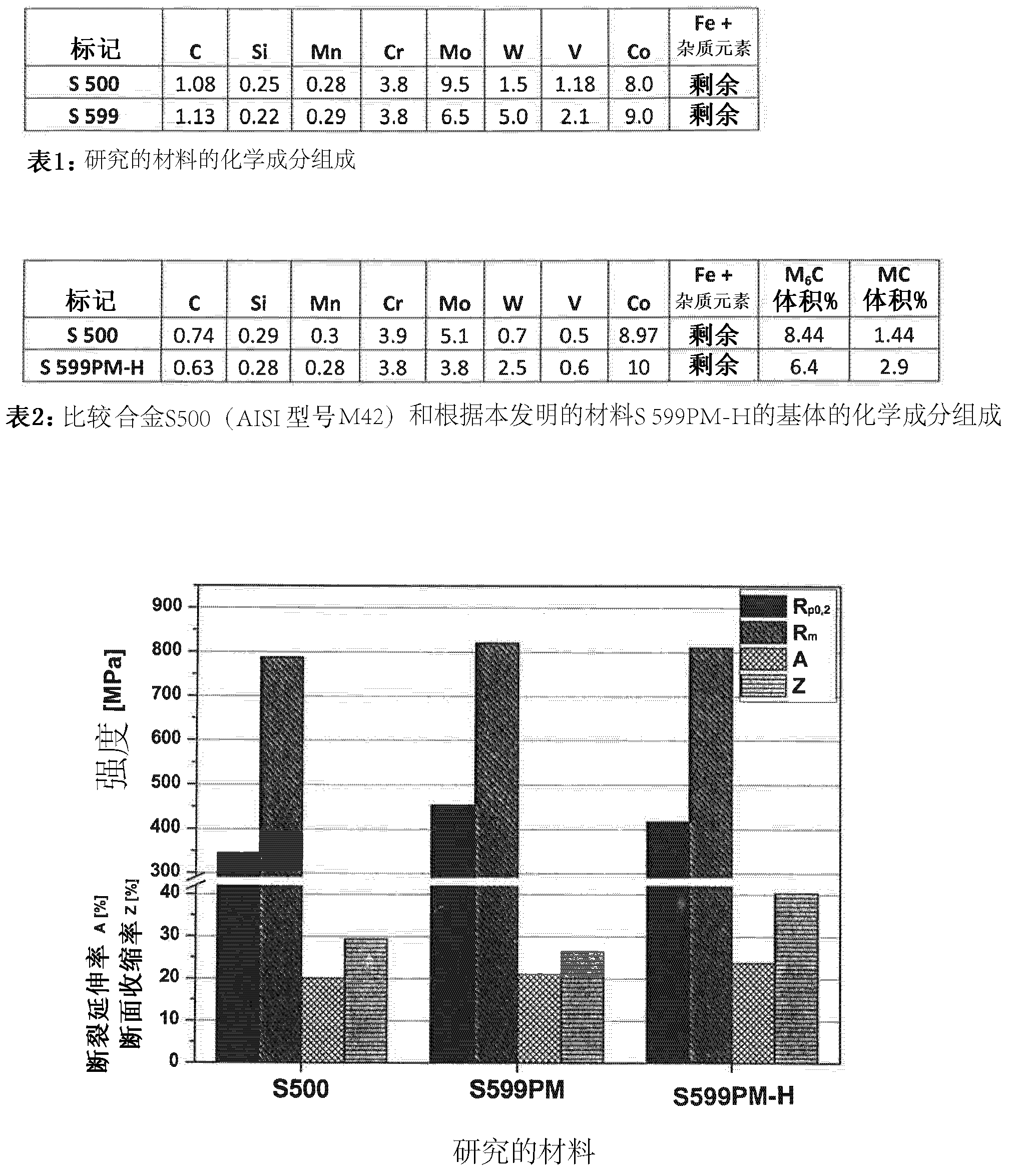

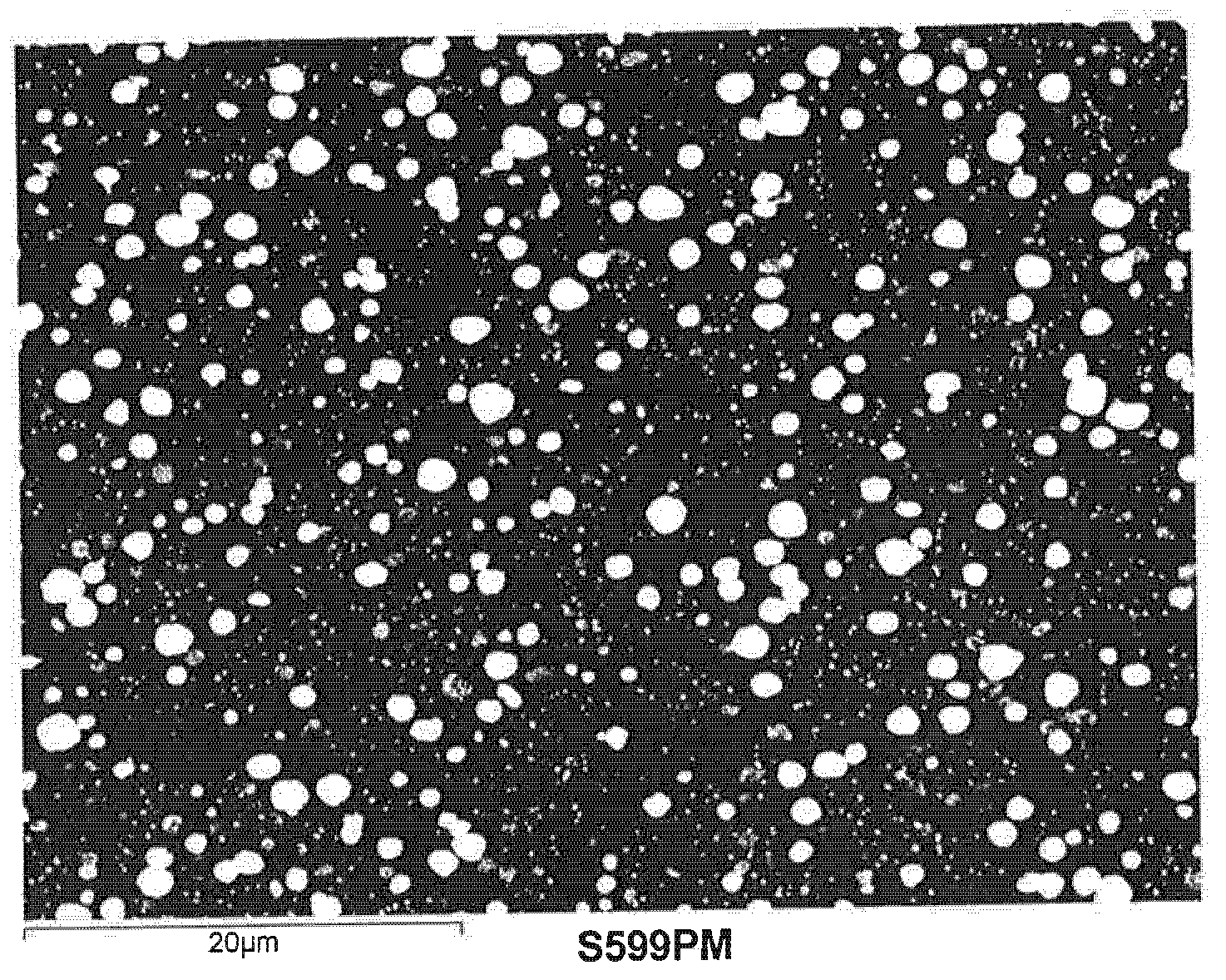

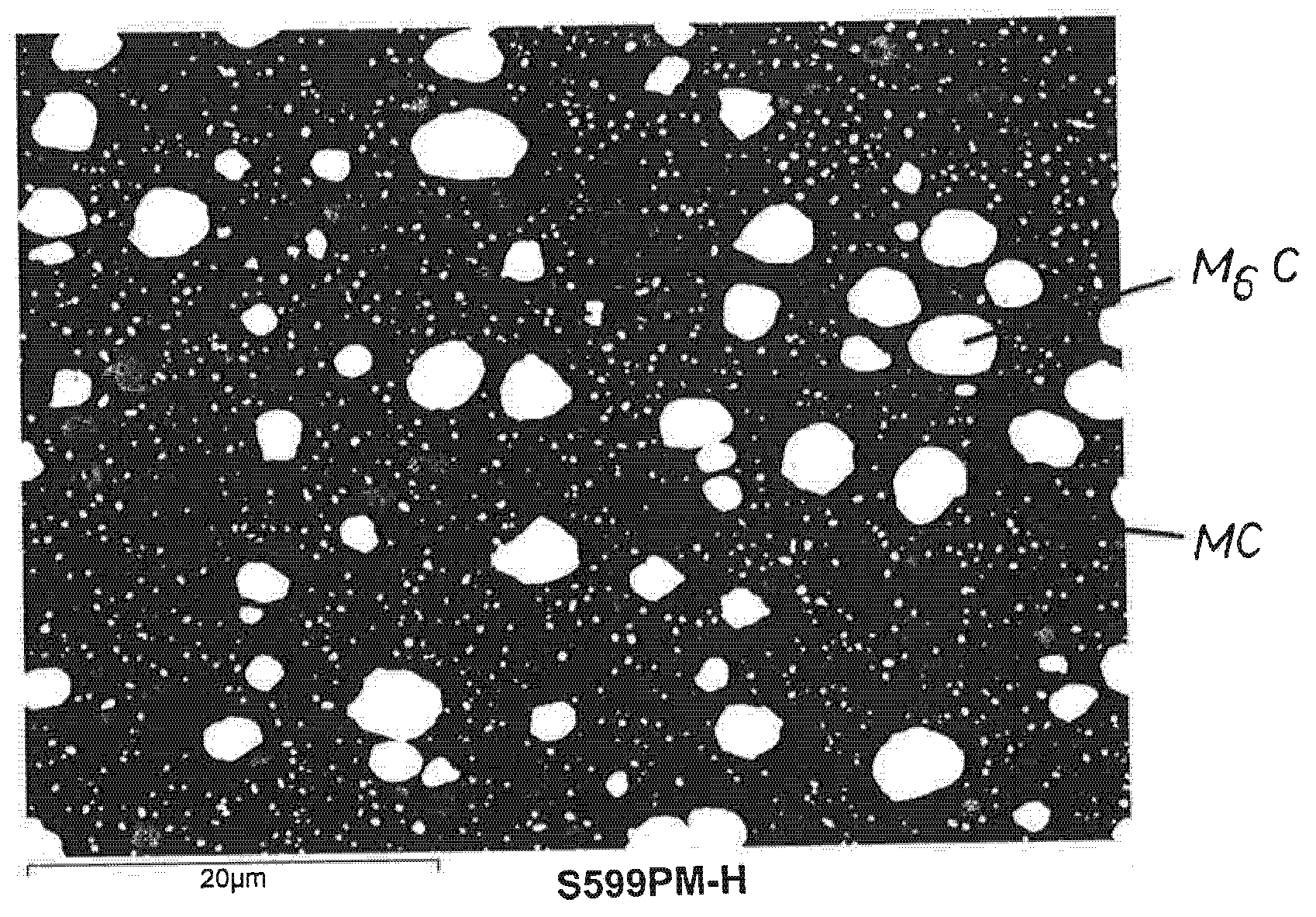

[0055] Table 1 shows the chemical composition of the standard alloy (AISI type M42) with the designation S500 and the chemical composition of the material S599PM produced by powder metallurgy, as well as the chemical composition of the material S599PM-H according to the invention.

[0056] A material with the designation S500 was used as a comparative raw material for general manufacturing, since this material has good wear properties (Verschleisseigenschaften) corresponding to the prior art.

[0057] An alloy corresponding to the composition marked S599 is melted and a HIP block is produced from the alloy by spraying the melt with nitrogen into a powder-filling mold and hot isostatic pressing it according to the PM method.

[0058] This HIP block is partly machined into test pieces and tools bearing the designation S599-PM in the usual manner.

[0059] At the second part of the block raw material composed of the melt, with a 100mm 2 A semi-finished product with a cross-secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com