Accurate heat treatment quenching technology of high-carbon high-chromium tool steel precise part

A technology for high-carbon chromium tools and precision parts, which is applied in the field of precise heat treatment and quenching technology, can solve the problems of complex heat treatment process, difficulty in reliably ensuring the uniformity and stability of crystal phase structure, and difficulty in quality control, achieving significant social benefits and Economic benefits, high engineering application value, effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

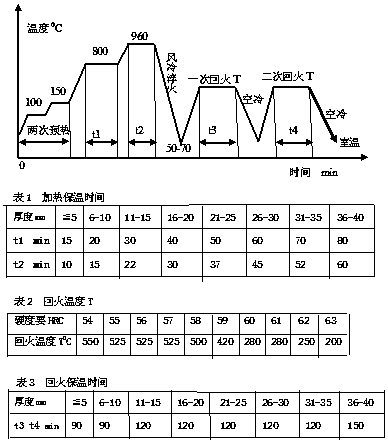

[0021] Example 1 High-carbon chromium tool steel precision punch with a thickness of 6-10mm, the hardness requirement is HRC56

[0022] (1) Put a batch of workpieces with a thickness of 6-10mm into the quenching furnace and preheat them twice, the first heating rate is less than 75°C / hour to 100°C, and the second heating rate is less than 115°C / hour Speed up to 150°C;

[0023] (2) The workpiece is heated to 800°C in the quenching furnace and held for 20 minutes, and then heated to the quenching temperature of 960°C and held for 15 minutes;

[0024] (3) Place the workpiece out of the furnace on the bracket, turn on the blower, and air-cool and quench the workpiece;

[0025] (4) When the workpiece is air-cooled to 50 0 When C-70℃, put it into the tempering furnace and heat it to 525 0 C Temper and keep warm for 90 minutes, then take out of the oven and cool in air naturally;

[0026] (5) When the workpiece is air-cooled to 50 0 C-70 0 C immediately into the tempering fur...

Embodiment 2

[0028] Example 2 High-carbon chromium tool steel precision punch with a thickness of 16-20mm, the hardness requirement is HRC58

[0029] (1) Put a batch of workpieces with a thickness of 16-20mm into the quenching furnace to preheat twice, the first heating rate is less than 75 ° C / hour to 100 ° C, the second heating rate is less than 115 ° C / hour Speed up to 150°C;

[0030] (2) The workpiece is heated to 800°C in the quenching furnace and held for 40 minutes, and then heated to the quenching temperature of 960°C and held for 30 minutes;

[0031] (3) Place the workpiece out of the furnace on the bracket, turn on the blower, and air-cool and quench the workpiece;

[0032] (4) When the workpiece is air-cooled to 50 0 When C-70℃, put it into the tempering furnace and heat it to 500 0 C Temper and keep warm for 120min, take out of the oven and cool in air naturally;

[0033] (5) When the workpiece is air-cooled to 50 0 C-70 0 C immediately into the tempering furnace fo...

Embodiment 3

[0035] Example 3 High-carbon chromium tool steel precision punch with a thickness of 26-30mm, the hardness requirement is HRC61

[0036] (1) Put a batch of workpieces with a thickness of 6-10mm into the quenching furnace and preheat them twice, the first heating rate is less than 75°C / hour to 100°C, and the second heating rate is less than 115°C / hour Speed up to 150°C;

[0037] (2) The workpiece is heated to 800°C in the quenching furnace and held for 60 minutes, and then heated to the quenching temperature of 960°C and held for 45 minutes;

[0038] (3) Place the workpiece out of the furnace on the bracket, turn on the blower, and air-cool and quench the workpiece;

[0039] (4) When the workpiece is air-cooled to 50 0 When C-70℃, put it into the tempering furnace and heat it to 280 0 C Temper and keep warm for 120min, take out of the oven and cool in air naturally;

[0040] (5) When the workpiece is air-cooled to 50 0C-70 0 C immediately into the tempering furnace for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com