Hight-performance semi-metal brake sheet material without asbestos

A high-performance, asbestos-free technology, applied in the field of brake pad materials, can solve the problems of low performance grade, low temperature resistance, and performance that need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

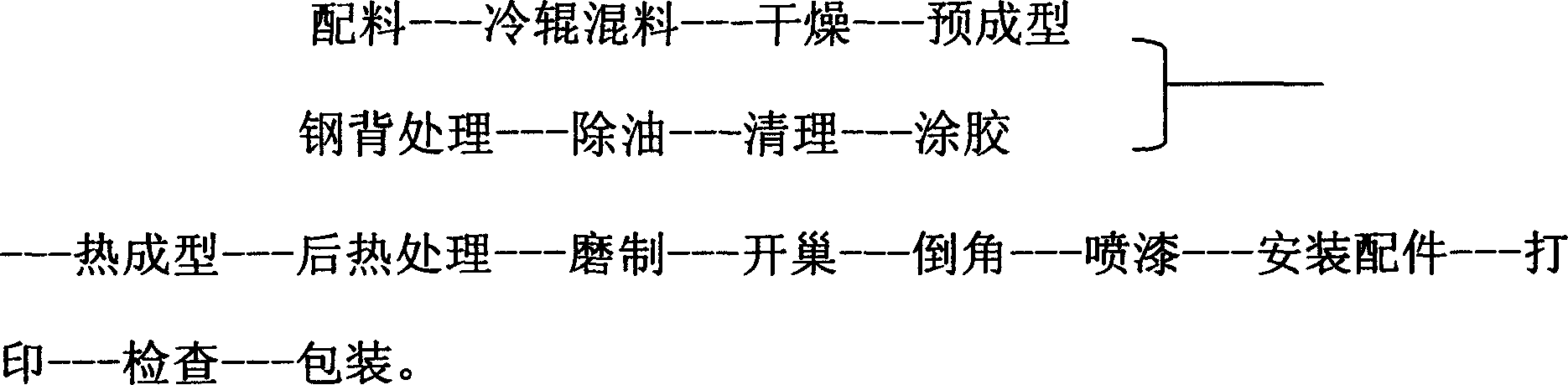

[0020] Example 1: The ingredients of this example are: 20 parts (parts by mass, the same below) of Lavaux phase strengthened iron-based alloy powder, and 8 parts of pure copper powder or bronze powder are compounded, and the powder size is 200 mesh; 17 parts The nano-butadiene cyanide rubber powder is compounded with 15 parts of modified phenolic resin, 0.75 parts of bisthiuram tetrasulfide, 0.75 parts of tetramethylthiuram trisulfide accelerator, particle size 200 mesh; 15 parts of short glass fiber, The length is not more than 7mm, 7% carbon fiber, the length is not more than 8mm; 7 parts of nano aluminum oxide and other fillers: 3 parts of flake graphite, 5 parts of sulfuric acid, 0.5 parts of sulfur and 1 part of boron nitride. Carry out the front wheel disc brake products of Xiali automobile according to the following process:

[0021]

[0022] The material performance test results conform to the US SAEJ661 standard. The friction coefficient at 350℃ is 0.438 (heating) ~ 0...

Embodiment 2

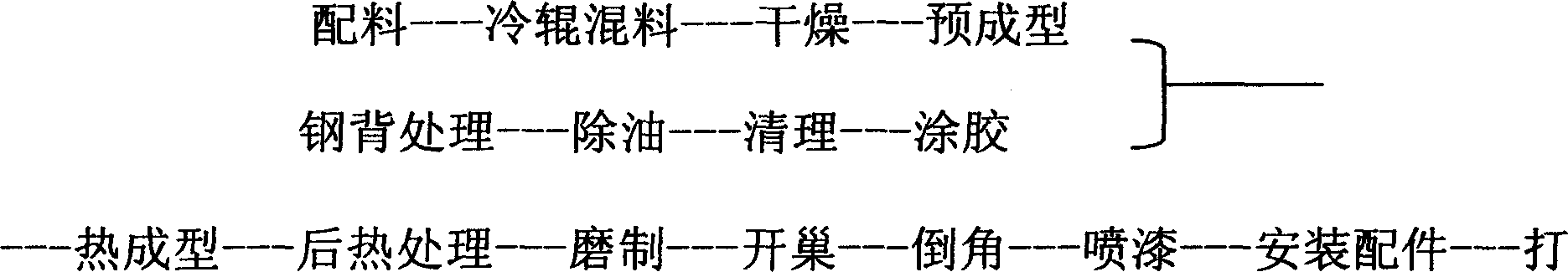

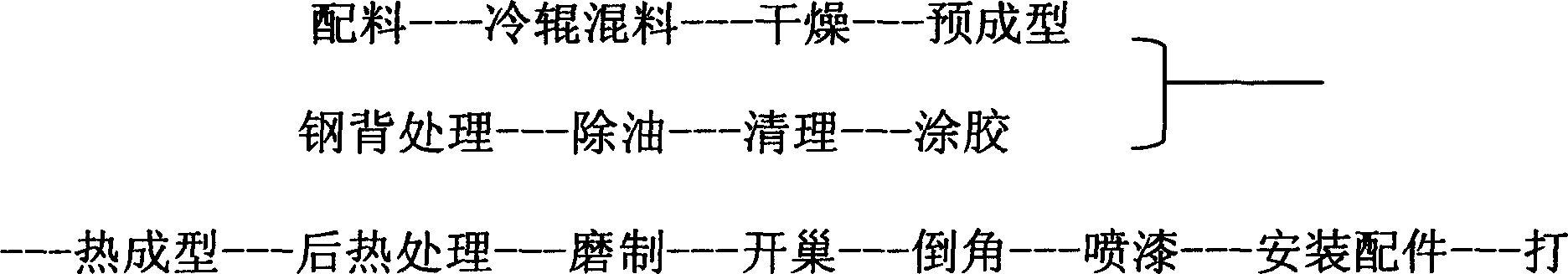

[0024] The ingredients of this embodiment are: 30 parts (parts by mass, the same below) of the Levy phase strengthened iron-based alloy powder, and compounded with 5 parts of pure copper powder or bronze powder, powder particle size 200 mesh; 8 parts of nano-butyronitrile Rubber powder, combined with 15 parts modified phenolic resin, 0.75 parts bisthiuram tetrasulfide, 0.75% tetramethylthiuram trisulfide accelerator, particle size 200 mesh; 10% short glass fiber and 5 parts steel fiber , Length not greater than 7mm, 3 parts carbon fiber and 4 parts natural sisal fiber, length not greater than 8mm; 7 parts nano aluminum oxide and other fillers: 4 parts flake graphite, 5.2 parts sulfuric acid pickaxe, 0.3 parts sulfur and 2 parts Parts of boron nitride. Carry out the front wheel disc brake products of Santana car according to the following process:

[0025]

[0026] The material performance test result conforms to the American SAEJ661 standard, the friction coefficient at 350℃ i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com