A laser repair method for the surface of ball-ground cast iron

A technology of ductile cast iron and laser repair, which is applied in the field of materials, can solve problems such as cracking at the interface between the cladding layer and the substrate, and achieve the effect of small thermal influence and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

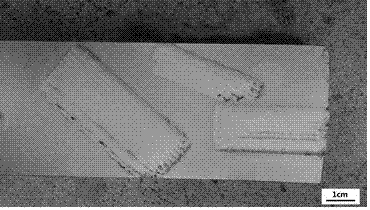

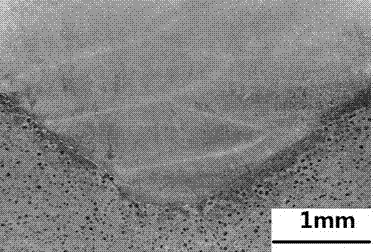

[0035] In this example, DILAS semiconductor laser is used for surface profiling repair on the QT500 alloy surface of 180mm×80mm×40mm. The specific repair process is as follows:

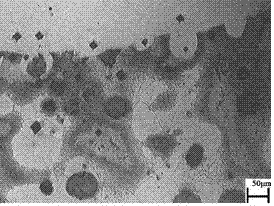

[0036] 1) Preparation of ball milled cast iron laser repair powder material, the repair powder material adopts Fe-15Cr-4Ni alloy powder, the alloy powder includes Cr element with a mass fraction of 14.92%, Ni element with 4.4%, Mo element with 1.96%, and Mo element with 0.73% Mn element, 0.34% Co element, the balance is Fe element.

[0037] 2) Clean the damaged part of the QT500 alloy mold; specifically, use a hand-held grinder to remove the oxide on the surface, remove the sharp corners on the pit wall, make the pit wall smoother, and the bottom is arc-shaped, and use acetone Clean the damaged area and surrounding surfaces.

[0038] 3) Preheat the QT500 alloy mold to be repaired to 200°C; specifically, put the QT500 alloy mold to be repaired on the electric blanket of the temperature-controllable re...

Embodiment 2

[0050] In this example, DILAS semiconductor laser is used for surface profiling repair on the QT500 alloy surface of 180mm×80mm×40mm. The specific repair process is as follows:

[0051] 1) Preparation of ball milled cast iron laser repair powder material, the repair powder material is Ni-5Cr alloy powder, the alloy powder contains 4.65% Cr element, 0.21% Co element, 0.17% Fe element, and the balance is Ni element .

[0052] 2) Clean the damaged part of the QT500 alloy mold; specifically, use a hand-held grinder to remove the oxide on the surface, remove the sharp corners on the pit wall, make the pit wall smoother, and the bottom is arc-shaped, and use acetone Clean the damaged area and surrounding surfaces.

[0053] 3) Preheat the QT500 alloy mold to be repaired to 200°C; specifically, put the QT500 alloy mold to be repaired on the electric blanket of the temperature-controllable resistance furnace, surround the electric blanket and the alloy with asbestos, and the electric ...

Embodiment 3

[0058] In this example, DILAS semiconductor laser is used for surface profiling repair on the QT500 alloy surface of 180mm×80mm×40mm. The specific repair process is as follows:

[0059] 1) Preparation of ball milled cast iron laser repair powder material, the repair powder material adopts Fe-15Cr-4Ni alloy powder, the alloy powder includes Cr element with a mass fraction of 14.92%, Ni element with 4.4%, Mo element with 1.96%, and Mo element with 0.73% Mn element, 0.34% Co element, the balance is Fe element.

[0060] 2) Clean the damaged part of the QT500 alloy mold; specifically, use a hand-held grinder to remove the oxide on the surface, remove the sharp corners on the pit wall, make the pit wall smoother, and the bottom is arc-shaped, and use acetone Clean the damaged area and surrounding surfaces.

[0061] 3) Preheat the QT500 alloy mold to be repaired to 200°C; specifically, put the QT500 alloy mold to be repaired on the electric blanket of the temperature-controllable re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com