Preparation process and preparation device of lead bismuth alloy for nuclear reactor

A lead-bismuth alloy and nuclear reactor technology is applied in the field of metal material processing, which can solve the problems of high equipment configuration requirements, increased oxidation, and need for mechanical stirring, and achieves the effects of reducing oxygen content, inhibiting volatilization, and accelerating crystallization speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

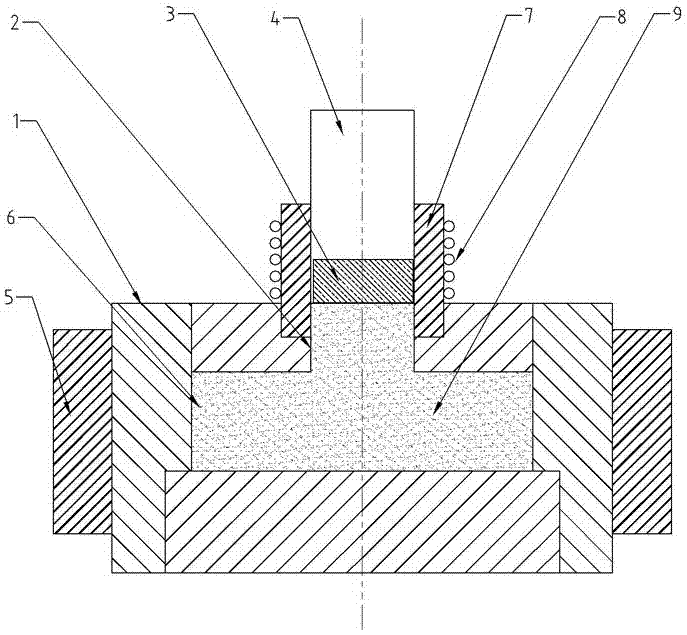

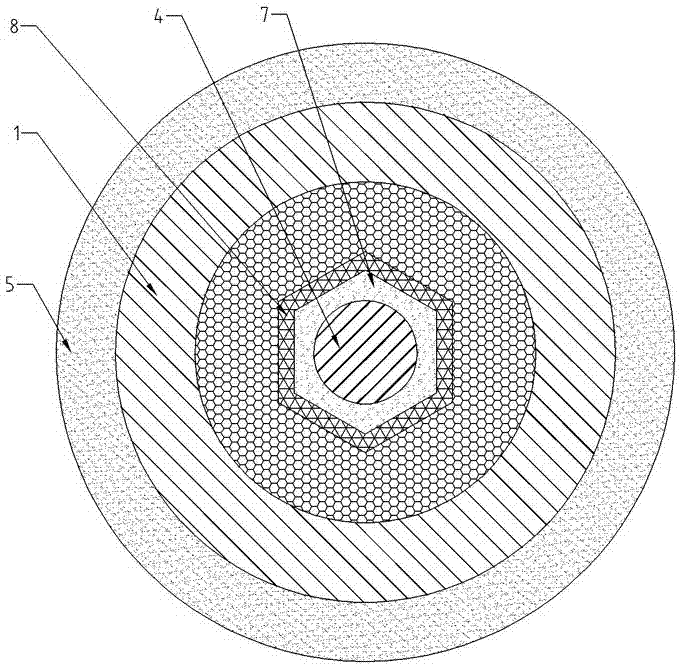

[0022] A preparation process for a nuclear reactor lead-bismuth alloy, comprising the steps of:

[0023] 1) The lead and bismuth ingots are batched according to the designed composition, and put into the crucible of the intermediate frequency induction furnace; the lead ingots used are national standard lead ingots, and the bismuth ingots used are low-silver, low-lead, high-purity bismuth ingots, and silver and lead impurities are The content is less than 250ppm;

[0024] 2) Turn on the nitrogen protection device to purge the crucible and ingredients in the furnace together, the nitrogen pressure is about 0.01-0.1Mpa; the mass percentage of the nitrogen purity is 99.99-99.999%;

[0025] 3) When the gas supply of the nitrogen protection device is uninterrupted, start the intermediate frequency induction furnace, start to heat up, and keep the melting temperature at 400-500°C. After the alloy is completely melted, increase the frequency of the intermediate frequency furnace, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com