Surface micro-melting treated cylinder jacket and preparation method thereof

A cylinder liner and micro-melting technology, applied in the field of cylinder liner, can solve the problems of high production scrap rate, limitation, high requirements for electroplating production line and tooling, and achieve high hardness and prevent cavitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

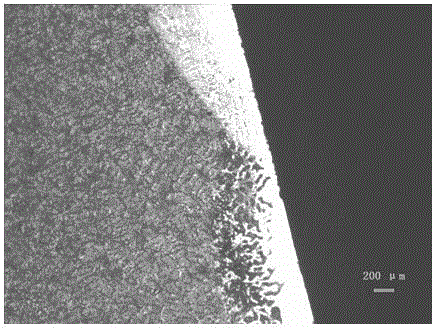

[0014] A method for surface micro-melting treatment of cylinder liners, which uses a laser beam (6KW cross-flow carbon dioxide laser, spot diameter 3mm, power 1.5KW, scanning pitch: 2.5mm) to scan the outer surface of the gray cast iron cylinder liner, and control The power density of the laser beam is 21KW / cm 2 , The scanning speed is 33mm / s, and after the scanning is finished, it is naturally cooled to room temperature.

[0015] Specifically, the material of the finished cylinder liner includes, but is not limited to, gray cast iron, compacted graphite iron, or nodular cast iron.

[0016] The cylinder liner prepared by the above method has a ledeburite structure on the outer surface, the depth of the hardened layer is 0.5-0.6mm, and the hardness is 50HRC.

Embodiment 2

[0018] A method for surface micro-melting treatment of cylinder liners, which uses a laser beam (6KW cross-flow carbon dioxide laser, spot diameter 3mm, power 1KW, scanning pitch: 2.2mm) to scan the outer surface of the finished vermicular graphite cast iron cylinder liner, and control The power density of the laser beam is 14.5KW / cm 2 , The scanning speed is 33mm / s, and after the scanning is finished, it is naturally cooled to room temperature.

[0019] The cylinder liner prepared by the above method has a ledeburite structure on the outer surface, the depth of the hardened layer is 0.45-0.48mm, and the hardness is 49HRC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com