Manufacturing method of high-wear-resistance compression roller shell made of ledeburite steel

A ledeburite steel, high wear resistance technology, used in manufacturing tools, furnace types, furnaces, etc., can solve the problems of inability to collect and clean debris inside the lathe, short service life, and no wear resistance. Safe and convenient to use, improve wear resistance and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

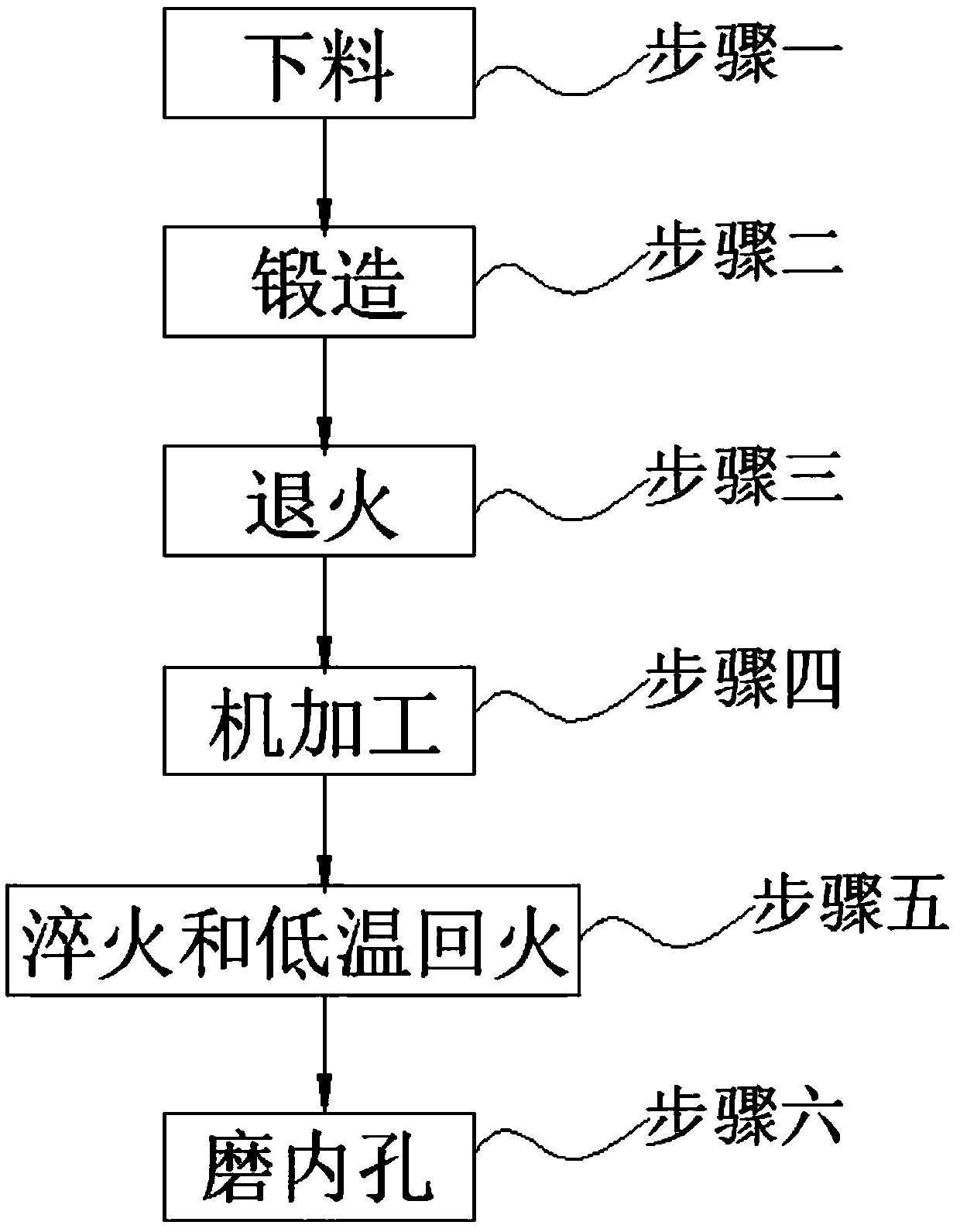

[0028] A method for manufacturing a ledeburite steel high wear resistance pressure roller shell, comprising step 1, blanking; step 2, forging; step 3, annealing; step 4, machining; step 5, quenching and low temperature tempering; step 6 , grinding the inner hole;

[0029] Manufacture 11133-V / C type pressure roller shell, the material grade of ledeburitic steel used is Cr12MoV, the chemical composition is carbon (C) = 1.45-1.70%, silicon (Si) ≤ 0.40%, manganese (Mn) ≤ 0.40%, Phosphorus (P) ≤ 0.025%, sulfur (S) ≤ 0.025%, chromium (Cr) = 11.00-12.50%, molybdenum (Mo) = 0.40-0.60%, vanadium (V) = 0.15-0.30%, the rest is iron and impurity elements;

[0030] In step 1, use ledeburite steel to integrally forge the blank of the pressure roller shell with a sawing machine, with a weight of 190kg and dimensions of X=340mm, Y=340mm, Z=220mm;

[0031] In step 2, the raw material is heated in a natural gas furnace, using segmental heating, the temperature of the furnace is 500-700°C, pre...

Embodiment 2

[0042] A method for manufacturing a ledeburite steel high wear resistance pressure roller shell, comprising step 1, blanking; step 2, forging; step 3, annealing; step 4, machining; step 5, quenching and low temperature tempering; step 6 , grinding the inner hole;

[0043] To manufacture the X9230-4a-V / D type pressure roller shell, the ledeburite steel material used is Cr12, and the chemical composition is carbon (C) = 2.00-2.30%, silicon (Si) ≤ 0.40%, manganese (Mn) ≤ 0.40 %, phosphorus (P) ≤ 0.025%, sulfur (S) ≤ 0.025%, chromium (Cr) = 11.50-13.00%, the rest are iron and impurity elements;

[0044] In step 1, use ledeburite steel to integrally forge the blank of the pressure roller shell with a sawing machine, the weight is 205kg, and the dimensions are X=340mm, Y=340mm, Z=230mm;

[0045] In step 2, the raw material is heated in a natural gas furnace, using segmental heating, the temperature of the furnace is 500-700°C, preheating for more than 3.5 hours, heating to 850°C at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com