Heat-conductive lubricating grease, adhesive, elastic composition, and cooling device

A thermally conductive, lubricating grease technology, used in the field of cooling devices, adhesives or elastomeric compositions, can solve problems such as machine misoperation, component temperature rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In the production method of this thermally conductive grease, etc., a base oil (resin), a surfactant, and a predetermined amount of mixed powder obtained by combining coarse and fine particles of thermally conductive inorganic powder are added, and the mixture is mixed with a mixer (such as a mixing mixer, A three-roll mill, a planetary mixer, a mixer (trimix, a double mixer) was used for kneading. Regarding the kneading conditions, it is necessary to examine the optimum conditions after confirming the hardness of the grease and the like and the pulverization of the particles.

[0032] The thermally conductive grease and the like of the present embodiment produced by the method described above can be used in the same applications as the conventional thermally conductive grease and the like.

[0033] The thermally conductive grease and the like according to the present embodiment are suitable for use on contact surfaces between heating elements and cooling elements of el...

Embodiment 1~15

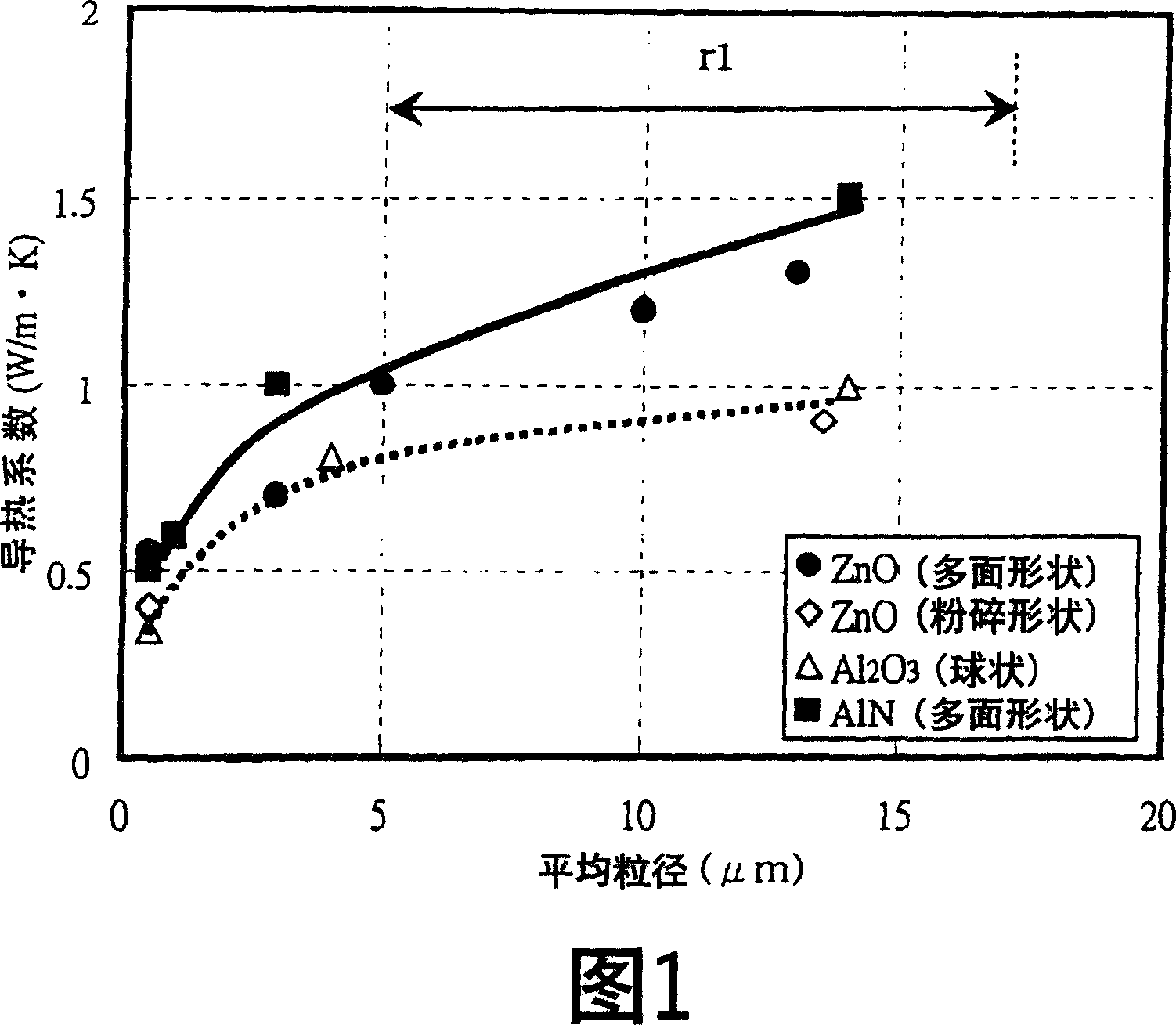

[0044] Table 1 and FIG. 1 show Examples 1-15. Using 3 kinds (ZnO, Al 2 o 3 , AlN) inorganic powder, four kinds of coarse powder monomers from different types of shapes (polyhedral shape, crushed shape, spherical shape), by changing the average particle size of the inorganic powder from 0.5 to 14 μm, the filling rate of the inorganic powder is 40vol%, Nonionic surfactant (decaglycerol pentaisostearate) 2.0wt%, base oil 60vol%, thereby preparing grease, and evaluating thermal conductivity.

[0045] The measurement results are shown in Table 1 and Fig. 1 . Also, the upward arrows in the table have the same meaning as above. As shown by the measurement results, increasing the average particle size of any powder can increase the thermal conductivity of grease, and further increasing the particle shape into a polyhedral shape (polygon) can greatly increase the thermal conductivity of grease.

[0046]

Embodiment 16~22

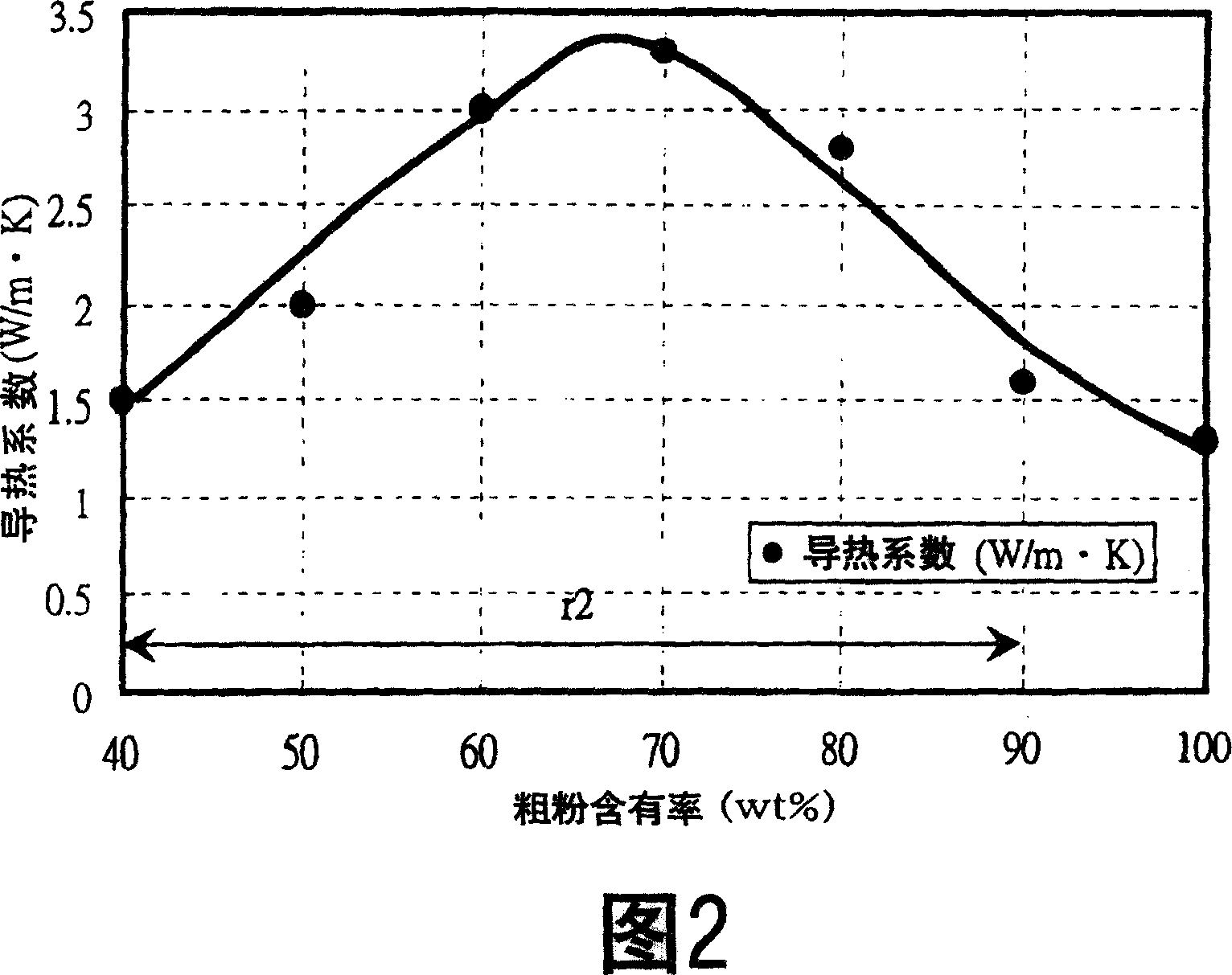

[0048] Table 2 and Fig. 2 show Examples 16-22. As the inorganic powder, zinc oxide with a multifaceted shape is used. With respect to 70% by volume of the mixed powder (the mixed powder is composed of 40% to 100% of coarse particles with an average particle diameter of 12.7 μm and 0 to 60% of fine particles with an average particle diameter of 0.6 μm Combination), mixed 2.0wt% nonionic surfactant (decaglycerol pentaisostearate), and 30 volume% base oil to prepare grease, and evaluated thermal conductivity and consistency.

[0049] The measurement results are shown in Table 2 and Fig. 2, and the content of the coarse powder greatly controls the thermal conductivity of the grease. A high thermal conductivity can be obtained if the coarse particle content is made to be about 70 wt%.

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com