Liquid-phase sintered SiC non-linear resistance ceramic and preparation method thereof

A non-linear resistance and ceramic preparation technology, applied in the field of SiC ceramics, can solve problems such as component failure, current and energy distribution differences, and achieve the effect of improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

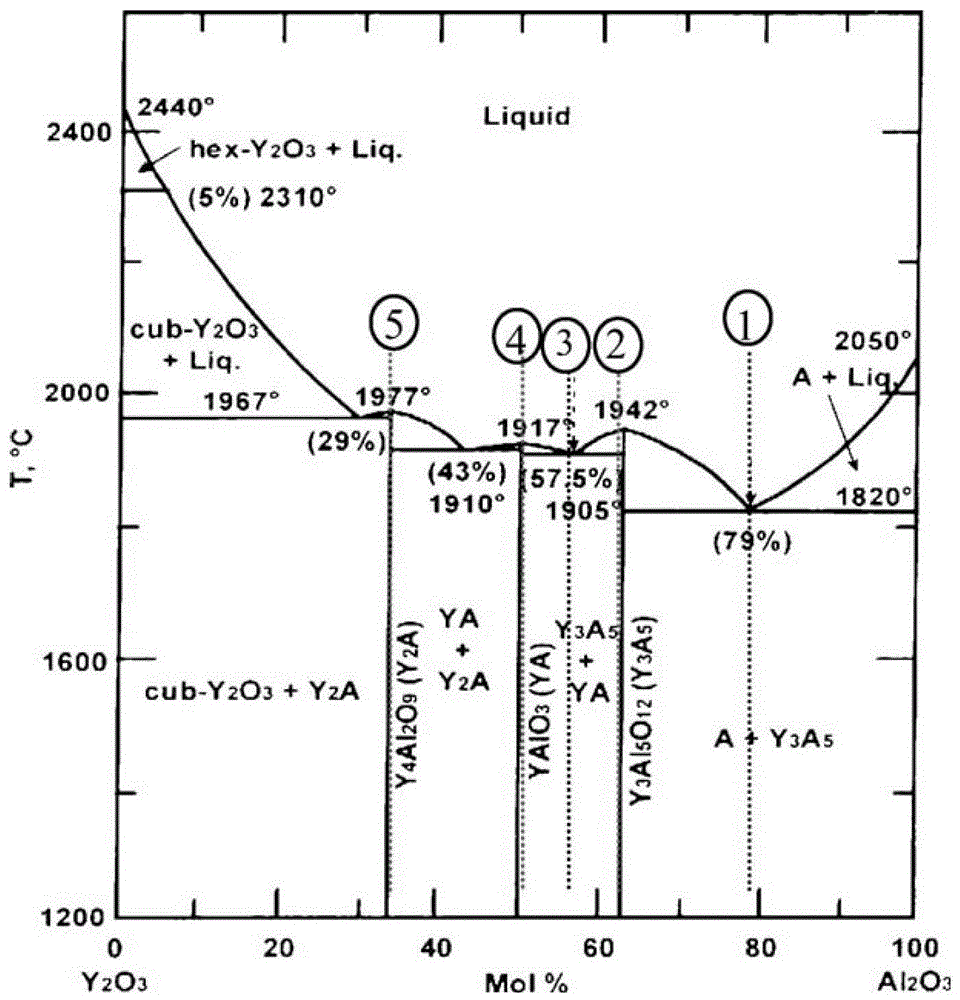

[0028] Preparation of slurry. SiC powder, Al 2 o 3 Powder and Y 2 o 3 The powder is used as a raw material to prepare a slurry. The Al 2 o 3 The particle size of the powder is less than 1 μm, the Y 2 o 3 The particle size of the powder is less than 1 μm, which is conducive to the formation of low melting point eutectic compounds. The slurry also contains a binder, which is added in an amount of 2wt% to 5wt% of the powder mass (the total mass of SiC and sintering aids), and organic substances such as PVA and PVB can also be formulated into a solution as required. As an example, SiC powder, sintering aid (Al 2 o 3 Powder and Y 2 o 3 Powder) and binder are prepared into a 40-45wt% slurry (the solvent of the slurry can be deionized water, ethanol, etc.), using SiC balls as grinding balls, powder: SiC balls = 1:2 (mass ), mixed for 24 hours to obtain the slurry. The solid content of the slurry prepared in the present invention is 40-45wt%. If the solid content is high...

Embodiment 1

[0040] To make Al 2 o 3 and Y 2 o 3 Mix evenly, the mass ratio Al 2 o 3 : Y 2 o 3 = 3:2 Al 2 o 3 and Y 2 o 3 The mixed powder is made into a 40wt% slurry (the solvent is deionized water), using SiC balls as grinding balls, powder: SiC balls = 1:2 (mass), mixed for 24 hours, then dried and sieved to obtain the required sintering aids;

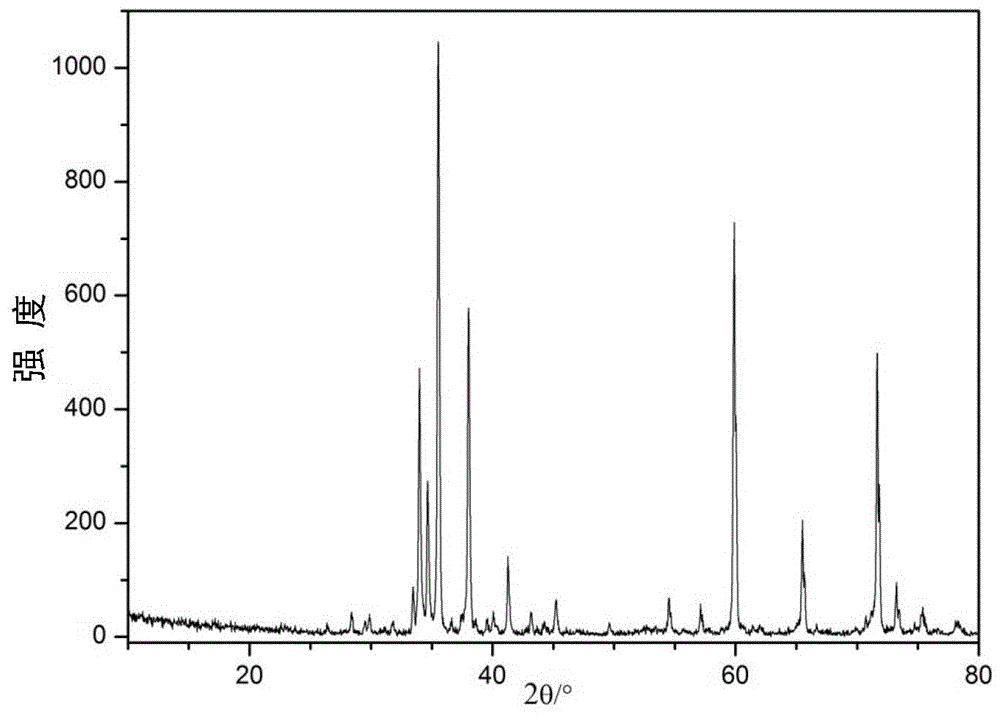

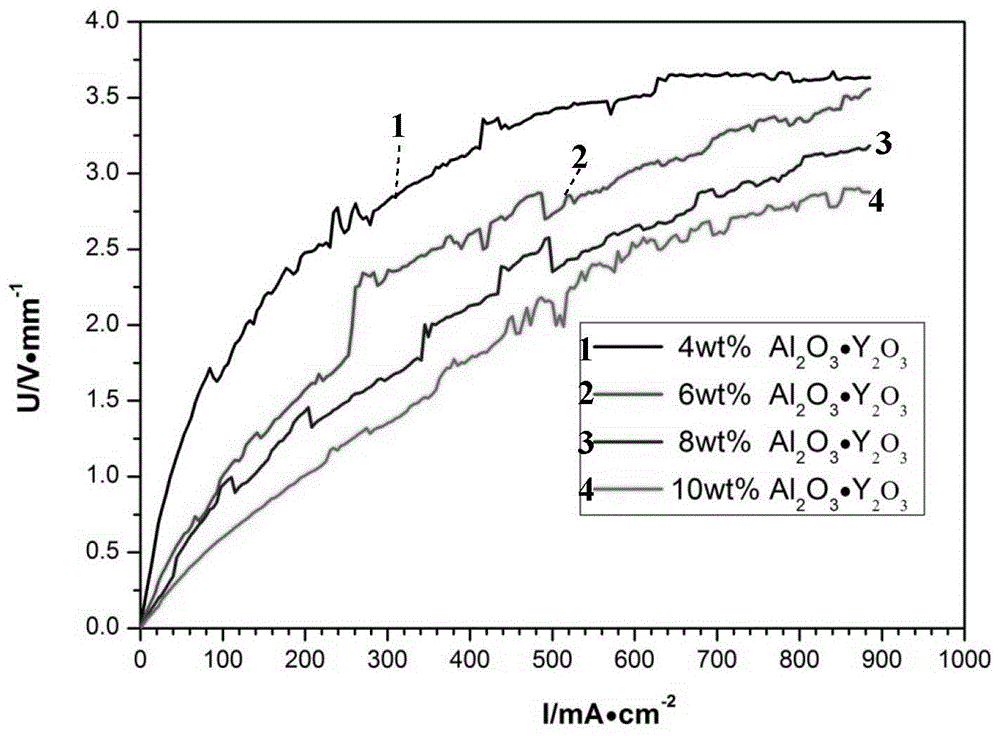

[0041] SiC powder, sintering aid Al 2 o 3 and Y 2 o 3 Powder mixture (mass ratio Al 2 o 3 : Y 2 o 3 =3:2, 4wt%) 100g in total, PVA is 2wt% of the powder (SiC and sintering aid), the powder is made into a slurry with a solid content of 45wt% (the solvent is deionized water), and the SiC ball 200g is ball milling medium, mixed for 24h. Then spray granulation, and the obtained powder is molded under a pressure of 16MPa on a flat vulcanizer, and then isostatically pressed under a pressure of 200MPa. After debonding, it was sintered under normal pressure Ar gas atmosphere, the sintering temperature was 1900°C, and the holding tim...

Embodiment 2

[0043] SiC powder, sintering aid Al 2 o 3 and Y 2 o 3 Powder mixture (mass ratio Al 2 o 3 : Y 2 o 3 =3:2, 6wt%) 100g in total, PVA is 2wt% of the powder, the powder is made into a slurry with a solid content of 45wt% (the solvent is deionized water), and 200g of SiC balls are used as the ball milling medium, and mixed for 24h . Then spray granulation, and the obtained powder is molded under a pressure of 16MPa on a flat vulcanizer, and then isostatically pressed under a pressure of 200MPa. After debonding, it was sintered under normal pressure Ar gas atmosphere, the sintering temperature was 1900°C, and the holding time was 1h. The obtained SiC non-linear resistor ceramic had a density of 3.16gcm -3 , the bending strength is 605MPa, the fracture toughness is 7.2MPam 1 / 2 . The obtained SiC non-linear resistor ceramics were made into small discs of Φ12mm and thickness 2mm, and silver paste electrodes were coated on both ends, and then kept in a muffle furnace at 750°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com