Preparation method for high-performance WC-Co nanocrystal cemented carbide

A cemented carbide and nanocrystalline technology is applied in the field of preparation of high-performance WC-Co nanocrystalline cemented carbide. The effect of low cost, high degree of densification and close connection of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] See Figure 1 to Figure 3 As shown, the method for preparing a high-performance WC-Co nanocrystalline cemented carbide of the present invention includes the following steps:

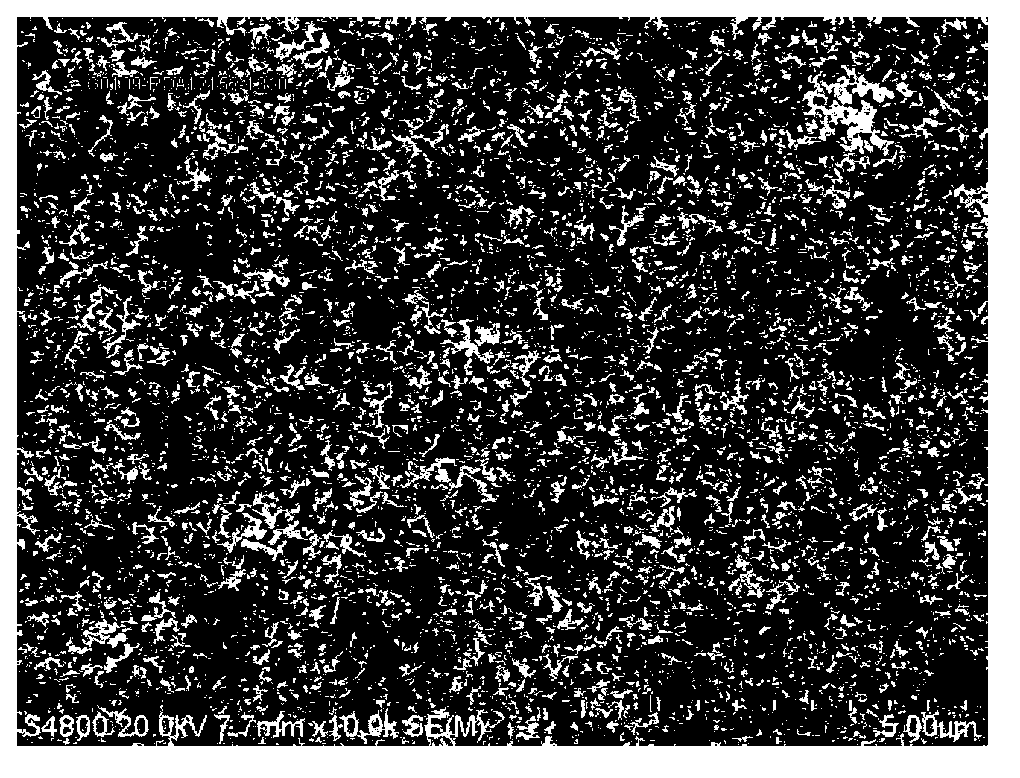

[0026] A. Mixture preparation steps: select WC (tungsten carbide) powder with an average particle size of 70nm (such as figure 1 As shown), add Co (cobalt) powder with an average particle size of 0.8um (such as figure 2 Shown), VC (vanadium carbide) powder with an average particle size of 1μm and Cr with an average particle size of 1μm 3 C 2 (Chromium carbide) powder is the raw material, of which Co powder accounts for 12wt% of the total raw material, VC powder accounts for 0.50wt% of the total raw material, and Cr 3 C 2 0.5wt% of the total raw material powder, the balance is nano WC powder, the above four powders (WC powder, Co powder, VC powder and Cr 3 C 2 Powder) constitute the total raw materials; paraffin wax is added as a forming agent, and the addition amount of paraffin wax is 2wt% of the ab...

Embodiment 2

[0031] See Figure 4 As shown, the method for preparing a high-performance WC-Co nanocrystalline cemented carbide of the present invention includes the following steps:

[0032] A. Mixture preparation steps: select WC powder with an average particle size of 100nm, add Co powder with an average particle size of 0.8um, VC powder with an average particle size of 1μm and Cr with an average particle size of 1μm 3 C 2 Powder is the raw material, of which, Co powder accounts for 13wt% of the total raw materials, VC powder accounts for 1.3wt% of the total raw materials, and Cr 3 C 2 0.9wt% of the total raw materials of the powder, the rest is nano-WC powder; paraffin wax is added as a forming agent, and the addition amount of paraffin wax is 2wt% of the above-mentioned total raw materials; then, anhydrous alcohol is used as a medium for wet grinding and mixing in a rolling ball mill The ratio of cemented carbide grinding balls to solid raw materials is 5.5:1, and the liquid-to-solid ratio...

Embodiment 3

[0037] See Figure 5 As shown, the method for preparing a high-performance WC-Co nanocrystalline cemented carbide of the present invention includes the following steps:

[0038] A. Mixture preparation steps: select WC powder with an average particle size of 200nm, add Co powder with an average particle size of 0.6um, VC powder with an average particle size of 1μm and Cr with an average particle size of 1μm 3 C 2 Powder is the raw material. Among them, Co powder accounts for 10wt% of the total raw materials, VC powder accounts for 0.45wt% of the total raw materials, and Cr 3 C 2 0.6wt% of the total powder raw materials, the rest is nano-WC powder; paraffin wax is added as a forming agent, and the addition amount of paraffin wax is 2wt% of the above-mentioned total raw materials; then, anhydrous alcohol is used as a medium for wet grinding and mixing in a rolling ball mill The ratio of cemented carbide grinding balls to solid raw materials is 7:1, and the liquid-to-solid ratio of an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com