Method for preparing WC-Co (tungsten carbide-cobalt) nano-powder

A technology of cobalt nano and tungsten carbide, applied in the direction of nanotechnology, can solve the problems of expensive fluidized bed equipment, high production cost, long reaction time, etc., achieve good sintering activity, reduce raw material cost and energy consumption, and low degree of agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 0.1mol ammonium metatungstate, 20mmol cobalt nitrate and 0.1mol citric acid, dissolve in 100ml deionized water to prepare a clear mixed solution; carry out complexation reaction in a water bath at 70°C for 5 hours; Dry for 12 hours to obtain a tungsten oxide-cobalt oxide precursor; calcinate the tungsten oxide-cobalt oxide precursor in an air atmosphere at 700°C for 1 hour to obtain a tungsten oxide-cobalt oxide powder.

[0029] Put the obtained tungsten oxide-cobalt oxide powder in a tube furnace, pass ammonia gas for nitriding, the flow rate of ammonia gas is controlled at 3L / min, the temperature is 750°C, the heating rate is 2°C / min, and the temperature is kept for 3 hours to obtain Tungsten nitride-cobalt nitride powder.

[0030] Mix 12 grams of tungsten nitride-cobalt nitride powder with 0.62 g of carbon black, use ethanol as a solvent and tungsten carbide-cobalt balls as a grinding medium, mix on a roller mill for 24 hours, and dry by rotary evaporation to o...

Embodiment 2

[0033] The difference between this example and Example 1 is that the obtained tungsten nitride-cobalt nitride powder is directly placed in a tube furnace, and a mixed gas of methane and hydrogen is passed through for carbonization. The volume ratio of methane to hydrogen is The ratio is 1:8, the flow rate of the mixed gas is 200ml / min, the carbonization temperature is 750°C, and the carbonization time is 2 hours to obtain WC-Co nanopowder with an average particle size of 45nm.

[0034] The rest of the content is exactly the same as described in Example 1.

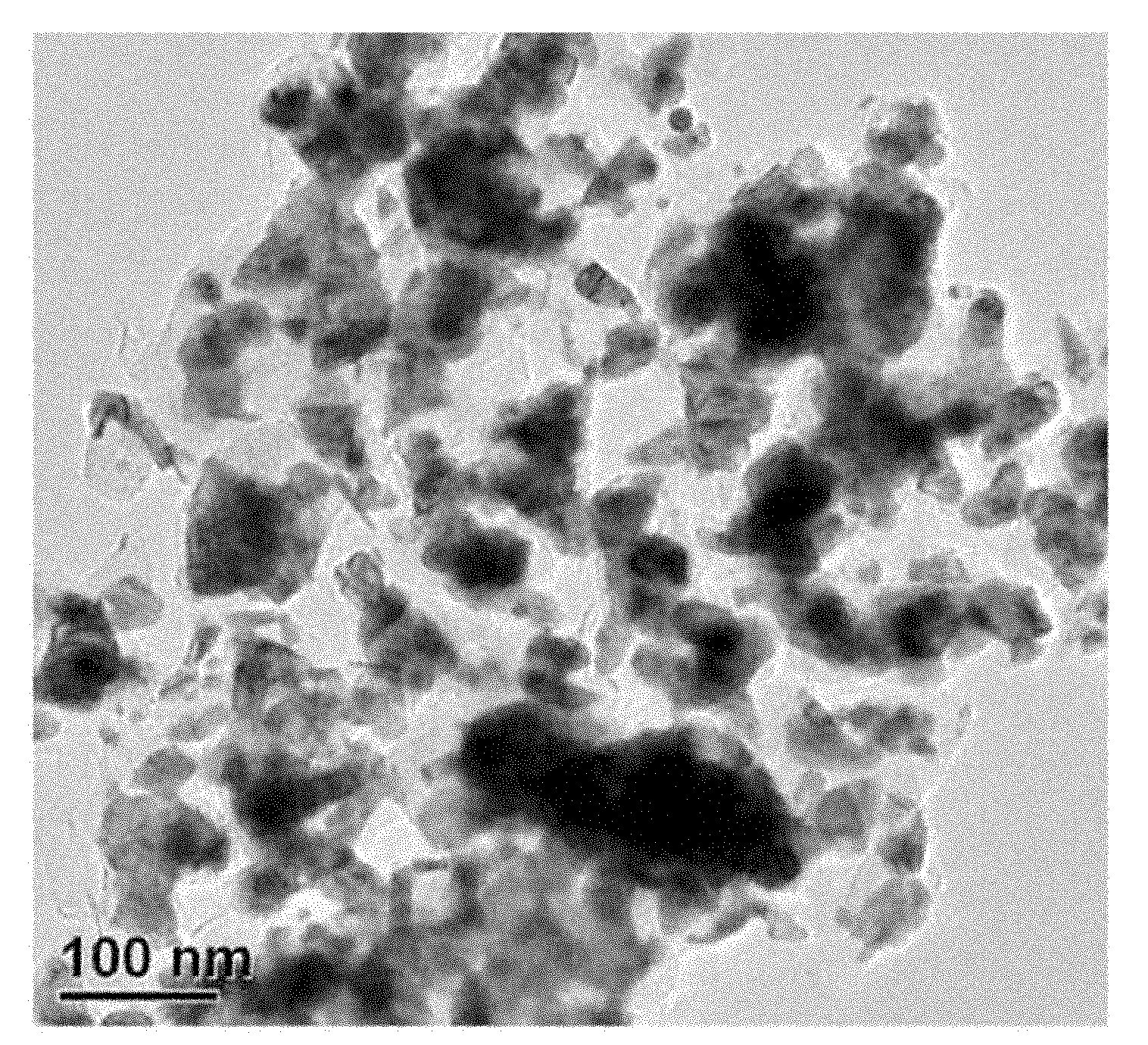

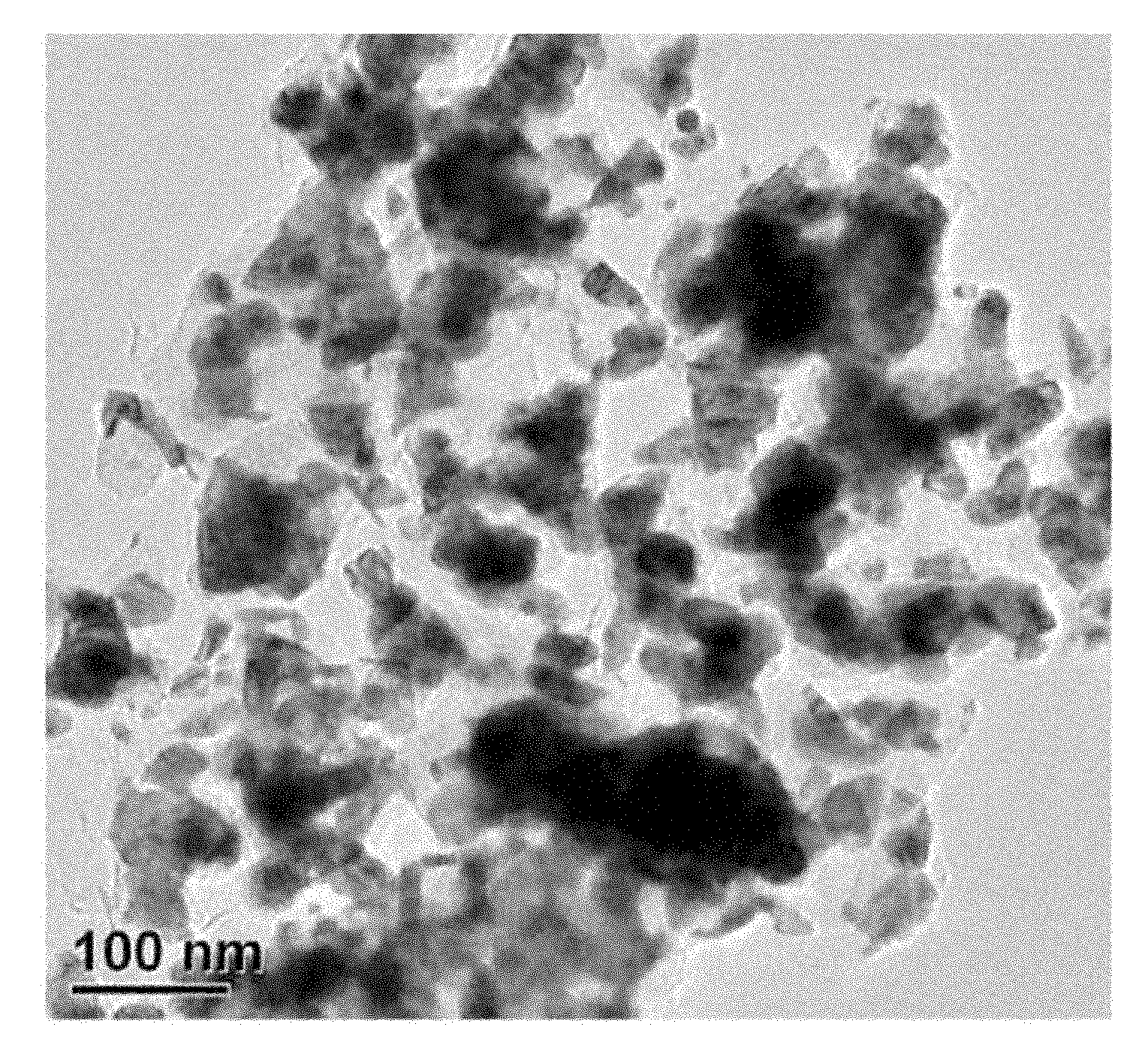

[0035] figure 1 It is the TEM photo of the WC-Co nanopowder made by figure 1 It can be seen that the powder particles are fine and the average particle size is 45nm.

[0036] The WC-Co nano-powder prepared in this example was sintered by hot pressing at 1200-1400°C / 1h and 25 MPa, and the relative density was higher than 97%, indicating that the prepared WC-Co nano-powder had good sintering activity.

Embodiment 3

[0038] The only difference between this example and Example 1 is that the obtained 12g tungsten nitride-cobalt nitride powder is mixed with 0.62g carbon black, put in a mixing tank, use ethanol as solvent, tungsten carbide ball As a grinding medium, it was mixed on a roller ball mill for 24 hours, and then dried by rotary evaporation to obtain W 2 N / CoN / C mixed dry powder, W 2 N / CoN / C mixed dry powder is placed in a graphite crucible, and argon gas is introduced into the sintering furnace, and the reactant is heated to 900°C and kept for 2 hours to obtain WC-Co nanopowder with an average particle size of 120nm.

[0039] The rest of the content is exactly the same as described in Example 1.

[0040] The WC-Co nano-powder prepared in this example was sintered by hot pressing at 1200-1400°C / 1h and 25 MPa, and the relative density was higher than 97%, indicating that the prepared WC-Co nano-powder had good sintering activity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com