Method for densifying wood and densified wood

A densification and wood technology, which is applied in wood treatment, wood processing equipment, wood treatment details, etc., can solve the problems of inability to obtain densified wood, difficult to achieve industrialization, harm to human health, etc., and achieves reduced production costs and simple equipment. , the effect of less volume loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

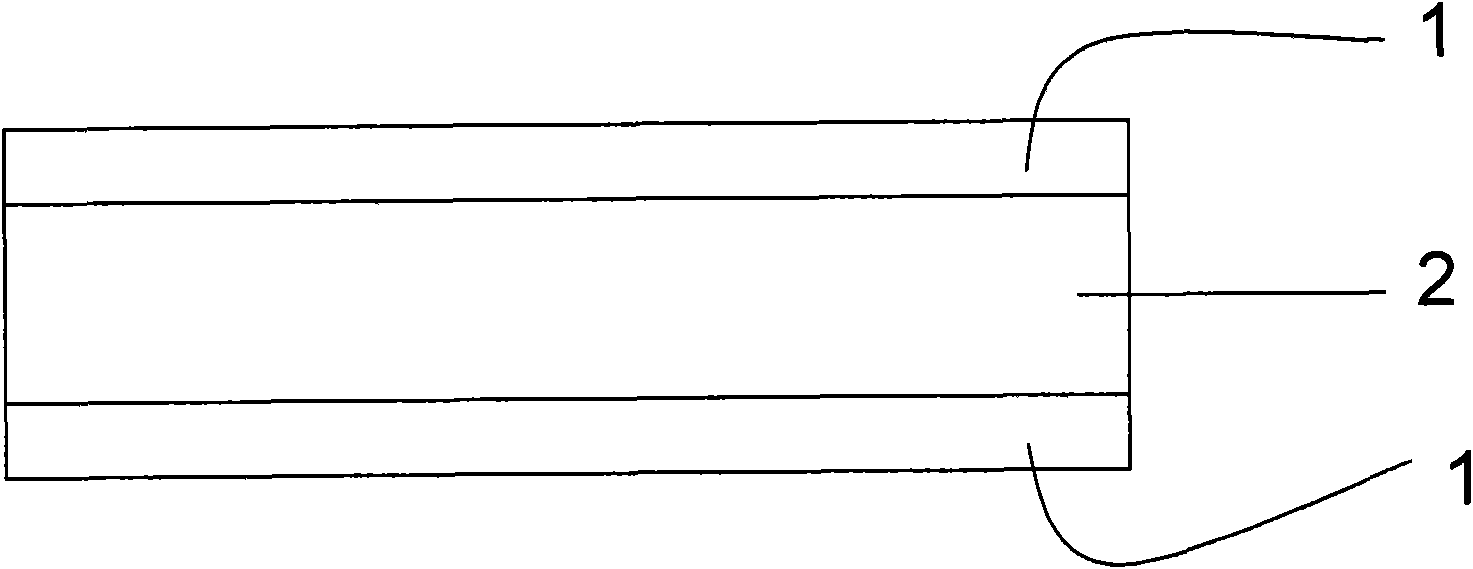

[0053] According to the first embodiment of the present invention, such as figure 1 As shown, the cross-sectional shape of the dense layer 1 is rectangular, and the dense layer 1 has two layers, the two dense layers are respectively located on the two surfaces of the wood, and the undensified layer 2 is distributed in the dense layer 1 . According to this embodiment, the ratio of the total thickness of the compacted layer to the thickness of the undensified layer may be 1:60-1:0.5, and more preferably the ratio of the thickness of the compacted layer to the thickness of the undensified layer is 1:20-1 : 0.1. The thickness of one dense layer may be equal to or not equal to the thickness of another dense layer.

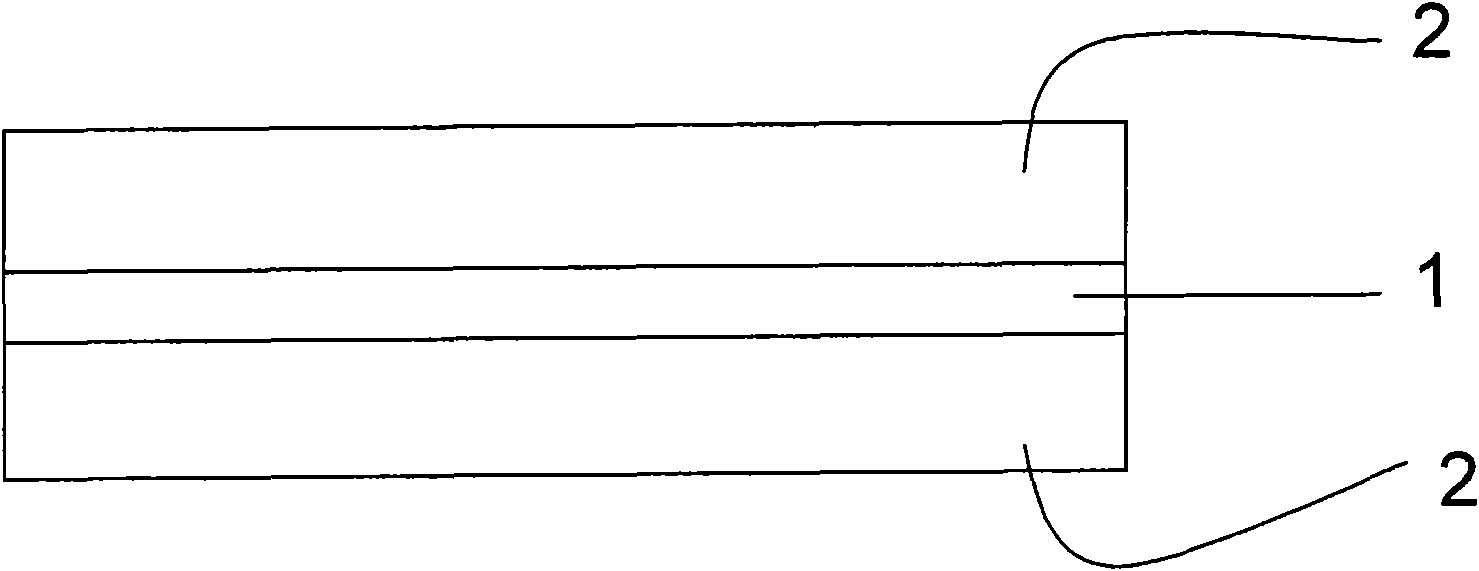

[0054] According to the second embodiment of the present invention, such as figure 2 As shown, the cross-sectional shape of the dense layer 1 is rectangular, and the dense layer 1 is one layer, and the undense layer 2 is two layers, and the dense layer 1 is located b...

Embodiment 1

[0066] This embodiment is used to illustrate the wood densification method provided by the present invention and the densified wood obtained by the wood densification method.

[0067] The cross-section (i.e. two end faces) of the chord-direction plate with the size of 400mm (length) × 100mm (width) × 20mm (thickness) and moisture content of 7% by weight made of plantation poplar wood is 60°C with melting point. Seal with paraffin wax, the amount of paraffin wax is 1.09 grams, then soak the sealed plate in water at 20°C for 60 minutes, take out the plate (a layer of water is attached to the surface of the plate, and the amount of water attached is 27.93 grams) and place it on a hot press for preheating , the preheating temperature is 180°C, the preheating time is 30 seconds, and then the preheated plate is pressed on both sides in the radial direction for hot pressing, the compression ratio of hot pressing is 25%, and the hot pressing temperature is 180°C , the hot pressing pre...

Embodiment 2

[0075] This embodiment is used to illustrate the wood densification method provided by the present invention and the densified wood obtained by the wood densification method.

[0076] It is 60 ℃ of paraffin seals with fusing point that the size of the plantation poplar made is 400mm (length) * 100mm (width) * 20mm (thick), moisture content is 7% by weight, paraffin sealing, paraffin consumption 1.18 grams , and then soak the sealed plate in water at 20°C for 120 minutes, then take out the plate (a layer of water is attached to the surface of the plate, and the amount of water attached is 32.9 grams) and place it on a hot press for heating. The preheating temperature is 180°C. The preheating time is 20 seconds, and then the preheated plate is hot-pressed in the radial direction, the hot-pressing temperature is 180°C, the hot-pressing pressure is 16MPa, the hot-pressing speed is 2 mm / s, and then kept for 70 minutes. A compacted wood with a compression ratio of 25% can be obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com