Nano lithium titanate material with high-density structure and preparation method of nano lithium titanate material

A nano-lithium titanate, dense structure technology, applied in structural parts, chemical instruments and methods, titanium compounds, etc., can solve problems such as hindering the commercial application of lithium-ion batteries, the impact of commercialization progress, and the inability to form gas production reactions. , to achieve the effects of good Coulomb efficiency and cycle stability, controllable particle size and shape, and inhibiting the phenomenon of flatulence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

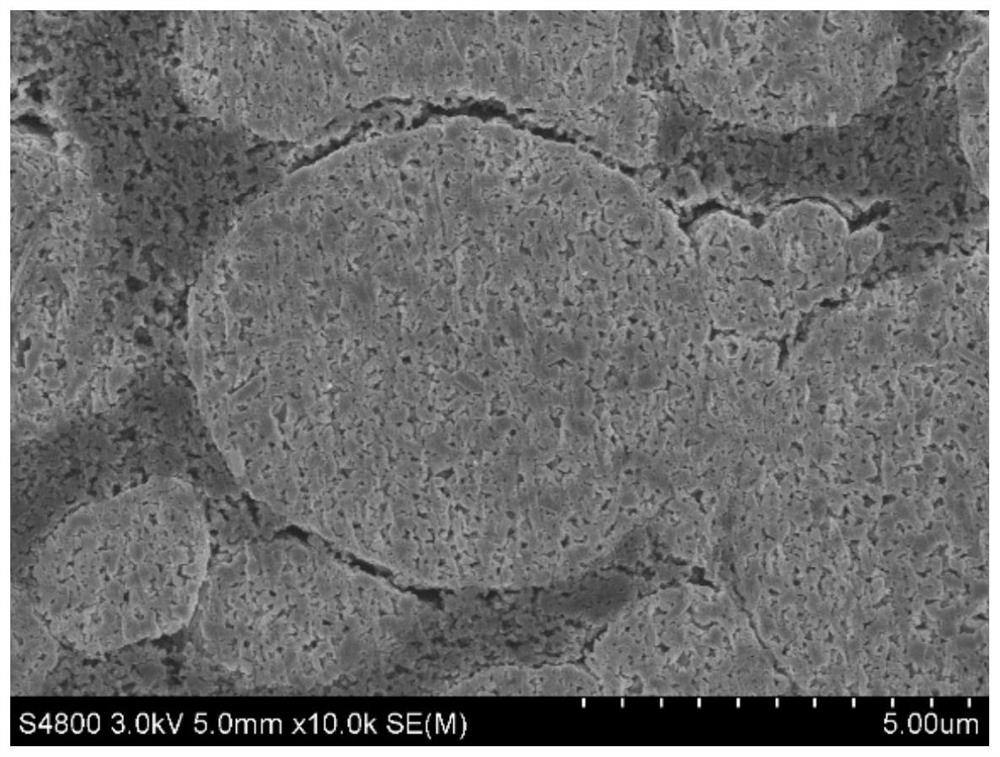

[0040] Add 5.0g CMC, 40.0g PEG and 2.0g niobium pentoxide to 2000mL ultrapure water and mix well, then add 1200.0g titanium dioxide powder, 230.0g lithium carbonate, 260.0g lithium hydroxide monohydrate to the above mixed solution In the process, add ultra-pure water to adjust the solid content of the slurry to 30%, and grind for 6 hours at a line speed of 14m / s to obtain a uniformly dispersed nano-precursor slurry, then transfer the precursor slurry and perform spray granulation, and control The temperature at the feed port is 240°C, the temperature at the discharge port is 110°C, and the spray parameters are controlled to obtain a spherical nano-precursor powder with a median particle size of D50=4μm. Finally, the spherical nano-precursor powder is transferred to a muffle furnace for solid-state reaction. The temperature is 850° C., and the reaction time is 8 hours to obtain a nano-lithium titanate material with a high density structure. The nano-lithium titanate material is...

Embodiment 2

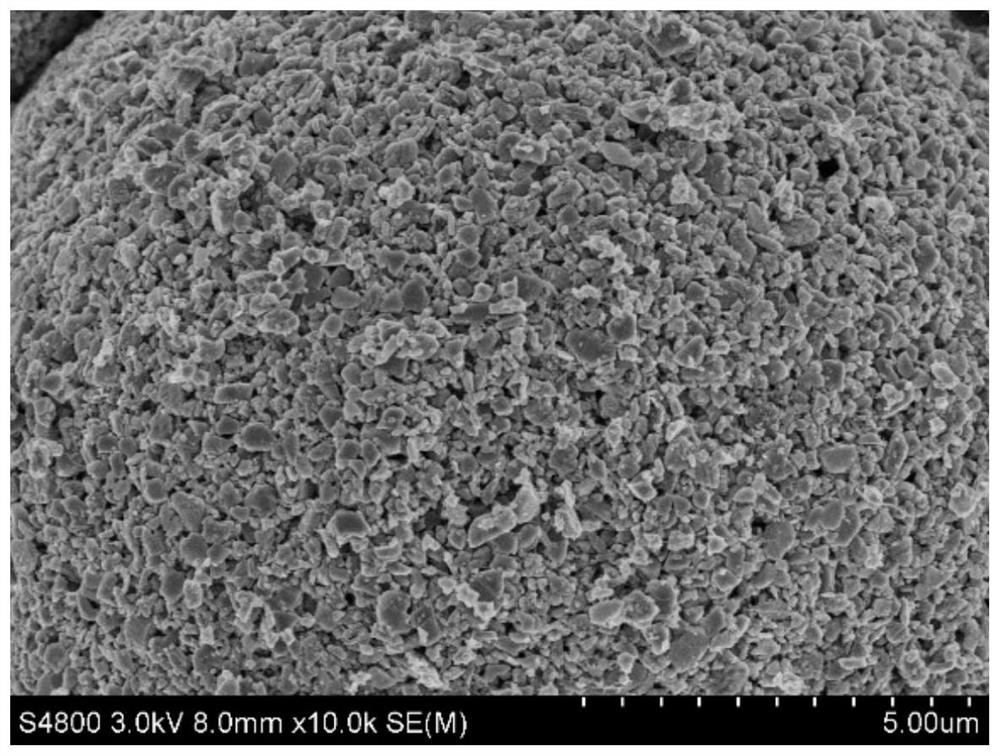

[0043] Compared with Example 1, the difference is that 5.0g CMC, 40.0g PVP and 2.0g tantalum pentoxide were added to 2000mL ultrapure water and mixed in turn, and then 1200.0g titanium dioxide powder, 230.0g lithium carbonate, 408.9g acetic acid Add lithium to the above mixed solution in turn, then add ultrapure water to adjust the solid content of the slurry to 35%, grind for 7 hours at a line speed of 14m / s to obtain a uniformly dispersed nano-precursor slurry, then transfer the precursor slurry and carry out Spray granulation, control the inlet temperature of 225°C, the outlet temperature of 100°C, control the spray parameters and obtain spherical nano-precursor powder with median particle size D50=4μm, and finally transfer the spherical nano-precursor powder to the muffle furnace A solid-state reaction was carried out at a reaction temperature of 800° C. and a reaction time of 9 hours to obtain a nano-lithium titanate material with a high density structure. The compacted d...

Embodiment 3

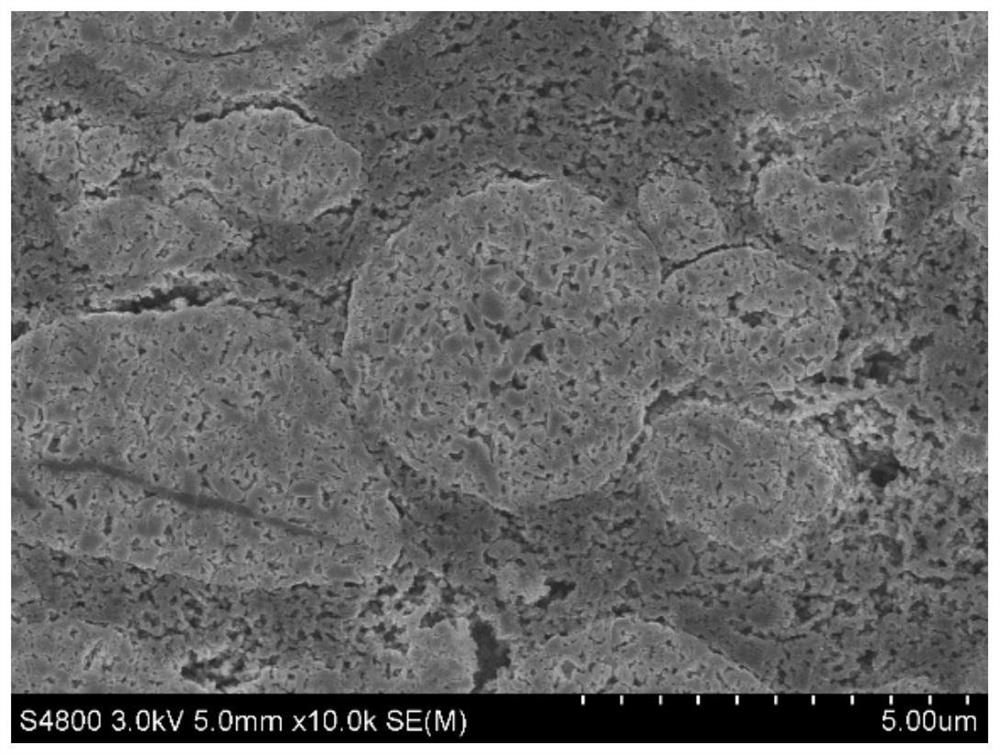

[0045] Compared with Example 1, the difference is that the titanium source is 1200.0g titanium dioxide, the lithium source is 187.3g lithium carbonate and 308.5g lithium hydroxide monohydrate. The compacted density of the prepared nano-lithium titanate material is shown in Table 1; the specific performance data after being assembled into a battery is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com