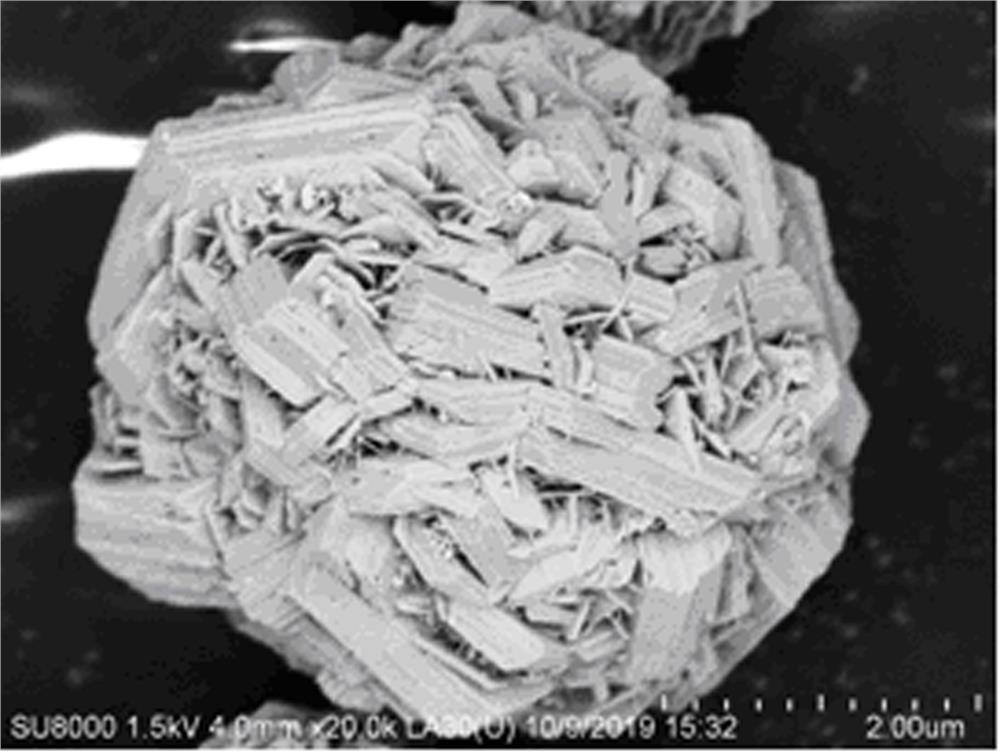

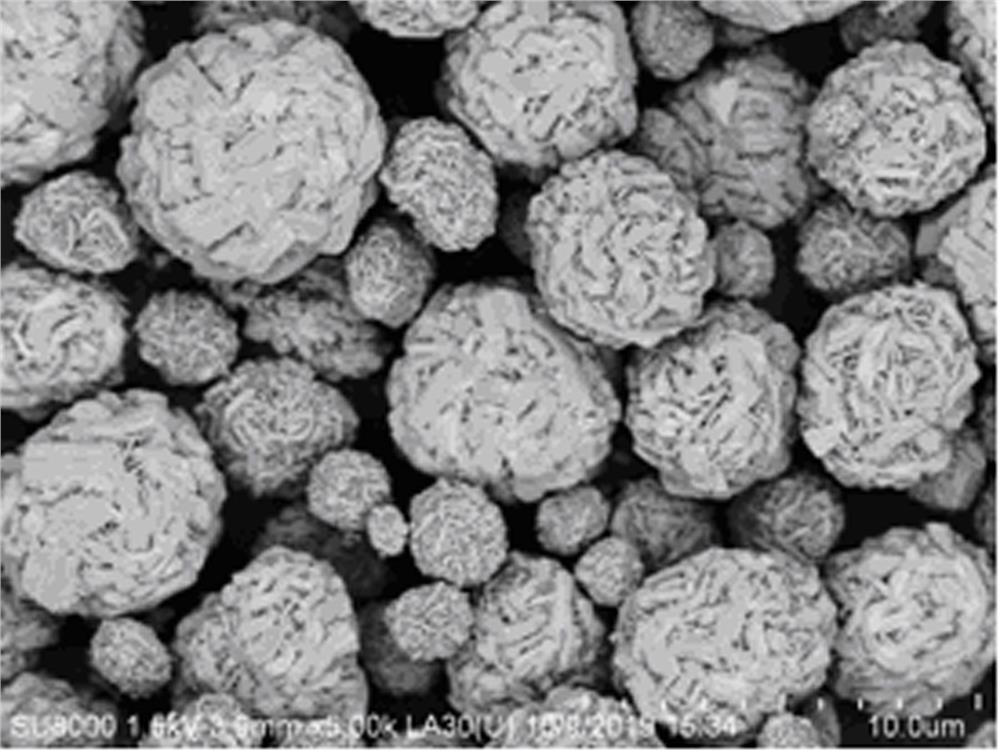

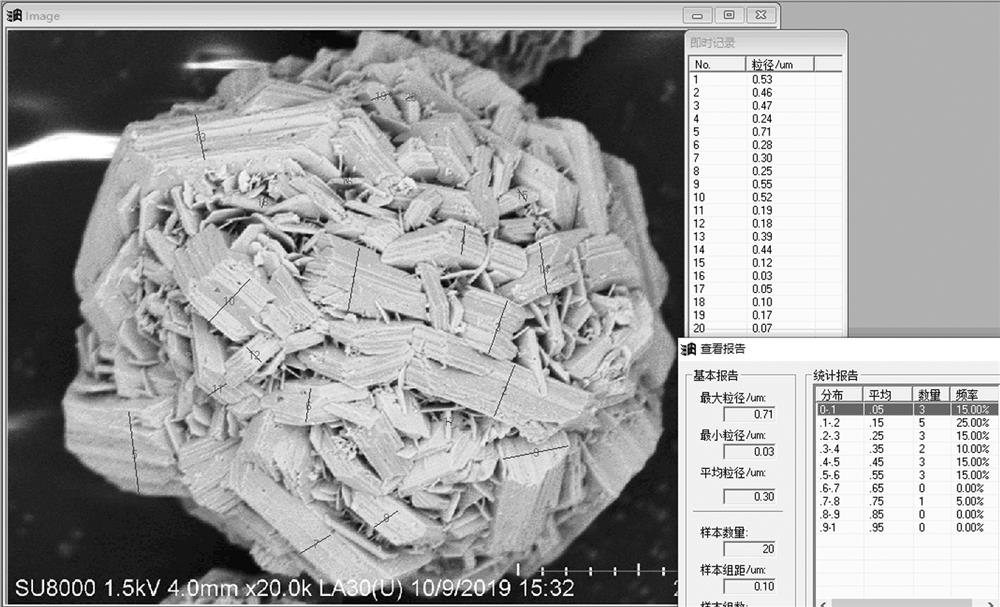

Laminated high-density spherical cobalt oxyhydroxide precursor and preparation method thereof

A cobalt oxyhydroxide, high-density technology, applied in chemical instruments and methods, cobalt oxide/cobalt hydroxide, cobalt compounds, etc., can solve the problems of uneven downstream mixing, non-spherical shape, poor product stability, etc. Achieve the effects of controllable particle size and morphology, improved capacity and cycle performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Prepare a cobalt sulfate solution with a cobalt ion concentration of 2mol / L, add 0.4g / L disodium edetate to the cobalt sulfate solution, and prepare a 10mol / L sodium hydroxide solution as a precipitant. Add 60L of pure water to a reactor with a capacity of 100L, control the temperature at 70°C, adjust the pH value to 11.0 with sodium hydroxide solution, stir at a speed of 550r / min, and keep feeding the reactor at a flow rate of 50L / h Inject air for 2h;

[0039] In the nucleation stage, the temperature is controlled at 70°C, the pH value is controlled at 10.7-11.0, the stirring speed is controlled at 550r / min, the cobalt salt feed flow is controlled at 4.5L / h, and the air flow is controlled at 120-200L / h. After the particles grow to 2.5 μm, switch the reaction conditions and enter the growth stage. In the growth stage, the temperature is controlled at 75°C, the pH value is controlled at 11.0-11.4, the stirring speed is controlled at 650r / min, the cobalt salt feed flow r...

Embodiment 2

[0047] Prepare a cobalt chloride solution with a metal concentration of 1.8mol / L, add 0.5g / L ethylenediaminetetraacetic acid to the cobalt chloride solution, and prepare an 8mol / L sodium hydroxide solution as a precipitant. Add 60L of pure water to a reactor with a capacity of 100L, control the temperature at 65°C, adjust the pH value to 10.85 with sodium hydroxide solution, stir at a speed of 500r / min, and keep feeding the reactor at a flow rate of 30L / h Inject air for 4 hours;

[0048] In the nucleation stage, the temperature is controlled at 60°C, the pH value is controlled at 10.7-11.0, the stirring speed is controlled at 500r / min, the cobalt salt feed flow rate is controlled at 4.0L / h, and the air flow rate is controlled at 120-200L / h. After the particles grow to 2.0 μm, switch the reaction conditions and enter the growth stage. In the growth stage, the temperature is controlled at 78°C, the pH value is controlled at 11.0-11.4, the stirring speed is controlled at 650r / mi...

Embodiment 3

[0051] Prepare a cobalt chloride solution with a metal concentration of 2.2mol / L, add 1.0g / L disodium edetate to the cobalt chloride solution, and prepare a 5mol / L potassium hydroxide solution as a precipitant. Add 60L of pure water to a reactor with a volume of 100L, control the temperature at 68°C, adjust the pH value to 11.0 with potassium hydroxide solution, stir at a speed of 500r / min, and keep feeding the reactor at a flow rate of 20L / h Introduce oxygen for 1h;

[0052] In the nucleation stage, the temperature is controlled at 68°C, the pH value is controlled at 10.7-11.0, the stirring speed is controlled at 500r / min, the cobalt salt feed flow rate is controlled at 4.0L / h, and the oxygen flow rate is controlled at 120-200L / h. After the particles grow to 2.0 μm, switch the reaction conditions and enter the growth stage. In the growth stage, the temperature is controlled at 75°C, the pH value is controlled at 11.0-11.4, the stirring speed is controlled at 650r / min, the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com