Process method for preparing nano zirconium dioxide by rapid homogeneous nucleation

A technology of nano-zirconia and process method, applied in the direction of zirconia, nanotechnology, nanotechnology, etc., can solve the problems of inorganic ammonium salt recovery pollution, particle agglomeration, loss of industrial utilization value, etc., and achieve particle size and morphology Controllable, narrow particle size distribution range, and the effect of reducing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Will be equipped with stabilizer cation Y 3+ (0.03mol) zirconium oxychloride (0.97mol) aqueous solution (5L) and 4mol ammonia gas were used to prepare the precursor in a jet reactor. The precursor obtained from the collection tube was washed to 2 . Tetragonal crystal products account for 94%, the product particle size distribution is concentrated around 120nm, and the product surface area is 18.5m 2 / g.

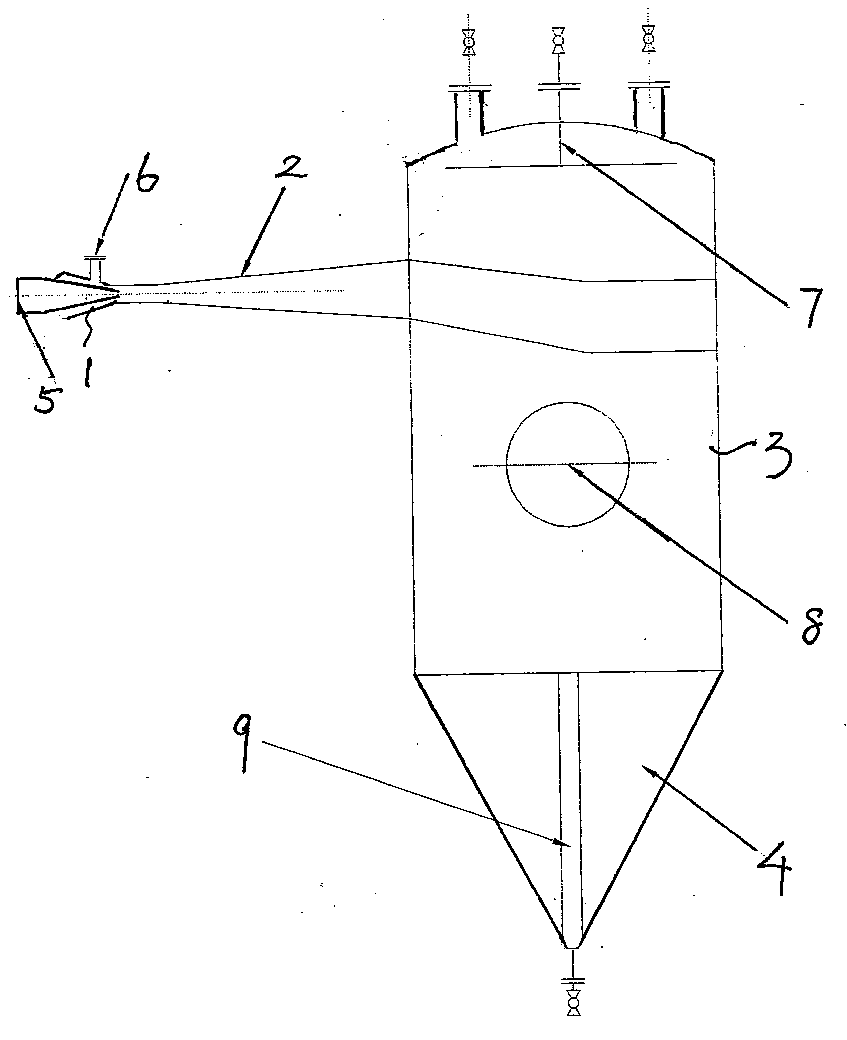

[0020] Described jet reactor comprises injector, and injector communicates with accepting cavity 3, and receiving hopper 4 is arranged below accepting cavity; Described injector comprises shower nozzle 1, injection pipe 2, and nozzle outlet communicates with the injection pipe connected with receiving chamber, The nozzle has two inlets 5 and 6, one of which is fed into zirconium salt solution, and the other is fed into ammonia or the mixed gas of ammonia and nitrogen. The injection pipe is in the form of an involute bell mouth. The length-to-diameter ratio of the r...

Embodiment 2

[0022] Will be equipped with stabilizer cation Y 3+ (0.08mol) zirconium oxychloride (0.92mol) aqueous solution (8L) and 4mol ammonia gas were used to prepare the precursor in a jet reactor. The precursor obtained from the collection tube was washed to 2 . Tetragonal crystal products account for 84%, the product particle size distribution is concentrated around 80nm, and the product surface area is 23.5m 2 / g. The jet reactor is the same as in Example 1.

Embodiment 3

[0024] Prepare pure zirconia nanopowder without adding mineralizers and stabilizer cations, hydrothermal synthesis conditions 250 ° C, pressure 4MPa, reaction time 24h, the rest are the same as in Example 1. The tetragonal phase is 92%, the particle size distribution is 100nm, and the specific surface area is 20.5 m2 / g. The jet reactor is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com