Preparation method of zero-water-absorption colored road marking material

A road marking and zero water absorption technology, applied in textiles and papermaking, can solve problems such as limited resources and chaotic colors, achieve excellent compact structure, increase wear resistance and durability, and prolong alkali resistance and aging resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

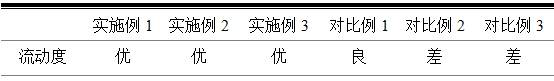

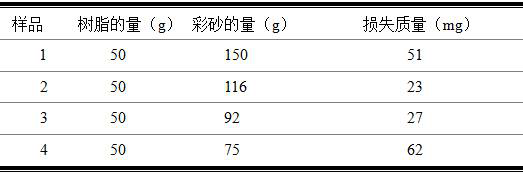

Embodiment 1

[0018] Step 1: Preparation of artificial glass colored sand by low temperature mechanical blending process

[0019] After placing 15 parts of waste glass particles in a planetary ball mill for 5 minutes, screen out 20-80 mesh waste glass particles with a sieve, and take the screened glass particles as aggregates. Take out 20 parts of mixed resin, use chrome yellow as a pigment, add distilled water, resin and pigment into a 250ml beaker, mix evenly, and stir for 5 minutes to obtain color glue. The aggregates, methyl cellulose ether and latex powder were then added to a beaker containing colored mucilage and placed in a mixer with a thermometer. Stir at 50°C, 500-700r / min for 20min, and dry in an oven at 50°C to obtain artificial glass colored sand.

[0020] Step 2: Preparation of road marking tape

[0021] Next, remove impurities, dust and dry the experimental bench, and lay the plastic film on the experimental bench. Cut out several 15cm×40cm rectangular grid cloths and pla...

Embodiment 2

[0023] Step 1: Preparation of artificial glass colored sand by low temperature mechanical blending process

[0024] After placing 15 parts of waste glass particles in a planetary ball mill for 5 minutes, screen out 20-80 mesh waste glass particles with a sieve, and take the screened glass particles as aggregates. Take out 10 parts of mixed resin, use chrome yellow as a pigment, add distilled water, resin and pigment into a 250ml beaker, mix evenly, and stir for 5 minutes to obtain color glue. The aggregates, methyl cellulose ether and latex powder were then added to a beaker containing colored mucilage and placed in a mixer with a thermometer. Stir at 50°C, 500-700r / min for 20min, and dry in an oven at 50°C to obtain artificial glass colored sand.

[0025] Step 2: Preparation of road marking tape

[0026] Next, remove impurities, dust and dry the experimental bench, and lay the plastic film on the experimental bench. Cut out several 15cm×40cm rectangular grid cloths and pla...

Embodiment 3

[0028] Step 1: Preparation of artificial glass colored sand by low temperature mechanical blending process

[0029] After placing 20 parts of waste glass particles in a planetary ball mill for 5 minutes, screen out 20-80 mesh waste glass particles with a sieve, and take the screened glass particles as aggregates. Take out 20 parts of mixed resin, use chrome yellow as a pigment, add distilled water, resin and pigment into a 250ml beaker, mix evenly, and stir for 5 minutes to obtain color glue. The aggregates, methyl cellulose ether and latex powder were then added to a beaker containing colored mucilage and placed in a mixer with a thermometer. Stir at 50°C, 500-700r / min for 20min, and dry in an oven at 50°C to obtain artificial glass colored sand.

[0030] Step 2: Preparation of road marking tape

[0031] Next, remove impurities, dust and dry the experimental bench, and lay the plastic film on the experimental bench. Cut out several 15cm×40cm rectangular grid cloths and pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com