Novel ternary thermal composite material and preparation method thereof

A thermal composite material and composite material technology are applied in the field of new ternary thermal composite materials and their preparation, which can solve the problem of increasing the difficulty and complexity of the process, increasing the difficulty of thermal expansion of the composite material, and unable to guarantee the thermal conductivity of the composite material. rate and other problems, to achieve the effects of low cost, wide application prospects and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

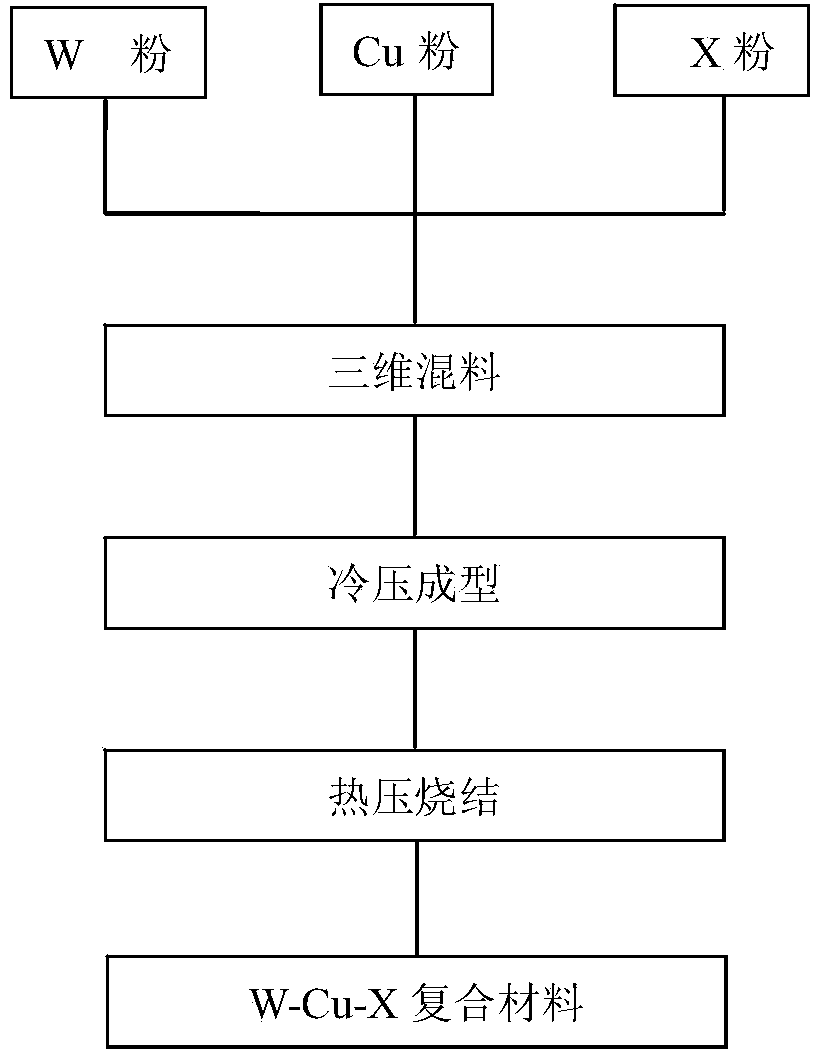

Method used

Image

Examples

Embodiment 1

[0024] Example 1: W-Cu-Diamond ternary thermal composite material

[0025] The volume fraction of each component is: Cu / (W+Cu+Diamond)=15~30%, (W+Diamond) / (W+Cu+Diamond)=70~85%, W / (W+Diamond) =70~100%, Diamond / (W+Diamond)=0~30%.

[0026] The purity of the Cu is 99.8%, and the particle size of its powder is 1-5 μm.

[0027] The purity of the W is 99%, and the particle size of its powder is 10-30 μm.

[0028] The purity of the Diamond is 99%, and the particle size of its powder is 5-10 μm.

Embodiment 2

[0029] Example 2: W-Cu-Diamond ternary thermal composite material

[0030] The volume fraction of each component is: Cu / (W+Cu+Diamond)=15%, (W+Diamond) / (W+Cu+Diamond)=85%, Diamond / (W+Diamond)=10%, W / (W+Diamond)=90%.

[0031] Others are with embodiment 1.

Embodiment 3

[0032] Example 3: W-Cu-Diamond Ternary Thermal Composite Material

[0033] The volume fraction of each component is: Cu / (W+Cu+Diamond)=30%, (W+Diamond) / (W+Cu+Diamond)=70%, Diamond / (W+Diamond)=30%, W / (W+Diamond)=70%.

[0034] Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com