Reduction distillation reaction device for sponge titanium production

The technology of a reaction device and titanium sponge is applied in the field of reaction devices for reduction distillation, which can solve the problems affecting the quality of titanium sponge, the self-weight of titanium sponge, and the long distillation time, so as to simplify the structure, reduce energy consumption, and reduce distillation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

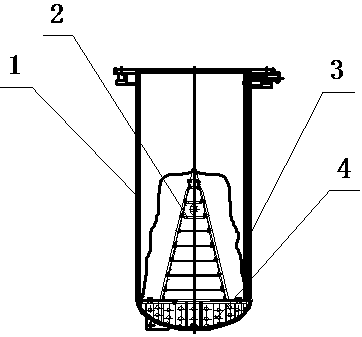

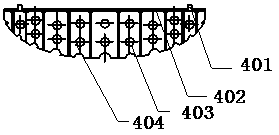

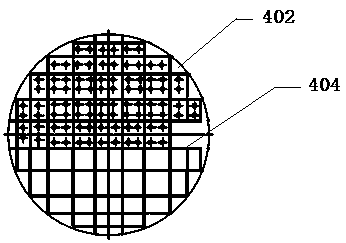

[0020] Such as figure 1 , figure 2 , image 3 As shown, a reduction distillation reaction device used in the production of sponge titanium is mainly composed of a reactor 1, a conical tower 2, a magnesium chloride tube 3, and a sieve plate 4, and the magnesium chloride tube 3 is arranged on one side of the reactor 1. The sieve plate 4 is arranged at the bottom of the reactor 1, and the conical tower 2 is welded on the sieve plate 4. The sieve plate 4 is composed of a support panel 402 and a well-shaped support frame connected below the support panel 402. On the support panel 402, There are several holes, and the well-shaped support frame is composed of several vertical plates 404 criss-crossing, each vertical plate 404 is provided with through holes 403, and the bottom of the well-shaped support frame is nearly hemispherical.

[0021] The supporting panel 402 is provided with an ejecting device 401 .

[0022] The well-shaped support frame and the support panel 402 are weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com