A kind of chemical-resistant high-density polyethylene resin and preparation method thereof

A high-density polyethylene and chemical-resistant technology, applied in the field of polymer chemistry, can solve the problems of limited chemical resistance of high-density polyethylene, and achieve the effects of excellent comprehensive performance, good dense structure and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

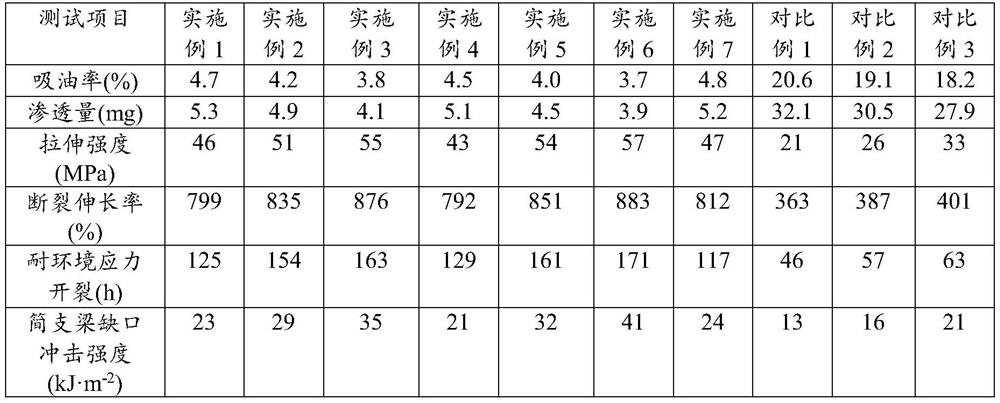

Examples

Embodiment 1

[0046] The raw material of the chemical-resistant high-density polyethylene resin of this embodiment includes the following components in parts by mass: 70 parts of high-density polyethylene, 10 parts of xanthan gum, 0.3 parts of di-tert-butyl peroxide, and 0.4 parts of triallyl Isocyanurate, 0.05 part tetrakis[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol, 0.10 part tris[2,4-di-tert-butylphenyl]phosphite ester, 1 part silicon carbide, 1 part polydiethynyl biphenyl.

[0047] The preparation method includes the following steps: taking each raw material according to the selected mass fraction and adding it to a high-speed mixer to mix evenly, adding the evenly mixed material to a special extruder for extrusion and granulation, and the temperature of the extruder is 180 DEG C. The rotational speed of the screw is 150 r / min, and the chemical-resistant high-density polyethylene resin is obtained.

Embodiment 2

[0049] The raw material of the chemical-resistant high-density polyethylene resin of this embodiment includes the following components in parts by mass: including 80 parts of high-density polyethylene, 13 parts of xanthan gum, 0.4 parts of di-tert-butyl peroxide, and 0.5 parts of triallyl Isocyanurate, 0.06 parts tetrakis[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propanoate]pentaerythritol, 0.12 parts tris[2,4-di-tert-butylphenyl]idene Phosphate ester, 3 parts boron nitride, 3 parts polydiethynyl biphenyl.

[0050] The preparation method includes the following steps: taking each raw material according to a selected mass fraction and adding it to a high-speed mixer to mix evenly, adding the evenly mixed material to a special extruder for extrusion and granulation, and the temperature of the extruder is 200 DEG C. The rotational speed of the screw is 100 r / min, and the chemical-resistant high-density polyethylene resin is obtained.

Embodiment 3

[0052] The raw material of the chemical-resistant high-density polyethylene resin of this embodiment includes the following components in parts by mass: 76 parts of high-density polyethylene, 15 parts of xanthan gum, 0.5 parts of di-tert-butyl peroxide, and 0.6 parts of triallyl Isocyanurate, 0.08 part tetrakis[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propanoate]pentaerythritol, 0.15 part tris[2,4-di-tert-butylphenyl]phosphite ester, 5 parts silicon phosphide, 5 parts polydiethynyl biphenyl.

[0053] The preparation method includes the following steps: taking each raw material according to a selected mass fraction and adding it to a high-speed mixer to mix evenly, adding the uniformly mixed material to a special extruder for extrusion and granulation, and the temperature of the extruder is 220 DEG C. The rotation speed of the screw is 80 r / min, and the chemical-resistant high-density polyethylene resin is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com