Cigarette filter capsule wall material and preparation method thereof

A technology of explosive beads and wall materials, which is applied in the fields of smoker's products, tobacco, and applications, can solve the problems of affecting the quality of aroma substances, migration of aroma substances, etc., to achieve good antioxidant effect, improve flavor, and improve the effect of dense structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

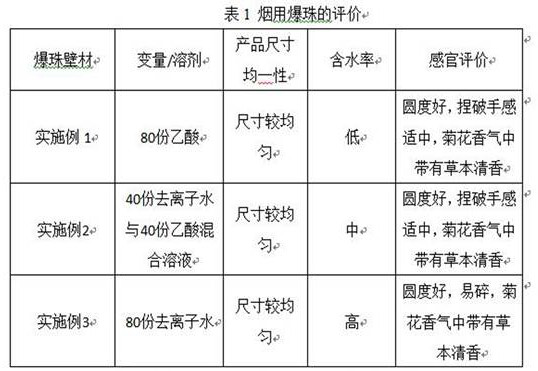

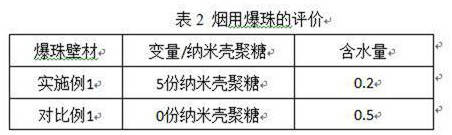

Embodiment 1

[0033] The invention discloses a method for preparing a wall material of popping beads for cigarettes.

[0034]Weigh 5 parts of amylose starch and disperse it in 80 parts of acetic acid, gelatinize at 70°C for 40 minutes to obtain mixed solution A, then add 5 parts of jelly jelly to mixed solution A, mix and stir at 80°C to obtain mixed solution B , adjust the pH of the mixed solution B to 6 with hydrochloric acid and sodium hydroxide solution, and finally add 5 parts of nano-chitosan and 1 part of sodium stearate to the mixed solution B, stir evenly, and obtain the molten bead wall after ultrasonic debubbling material.

Embodiment 2

[0036] The invention discloses a method for preparing a wall material of popping beads for cigarettes.

[0037] Weigh 5 parts of amylose starch and disperse it in a mixed solution of 40 parts of deionized water and 40 parts of acetic acid, and gelatinize at 70°C for 40 minutes to obtain mixed solution A, then add 5 parts of jelly jelly to mixed solution A, and heat at 80°C Mix and stir evenly to obtain a mixed solution B, adjust the pH of the mixed solution B to 6 with hydrochloric acid and sodium hydroxide solution, and finally add 5 parts of nano-chitosan and 1 part of sodium stearate to the mixed solution B, stir evenly, and ultrasonically remove air bubbles Finally, the blasting beads wall material in molten state is obtained.

Embodiment 3

[0039] The invention discloses a method for preparing a wall material of popping beads for cigarettes.

[0040] Weigh 5 parts of amylose starch and disperse it in 80 parts of deionized water, gelatinize at 70°C for 40 minutes to obtain a mixed solution A, then add 5 parts of jelly jelly to the mixed solution A, mix and stir at 80°C to obtain a mixed solution B. Adjust the pH of the mixed solution B to 6 with hydrochloric acid and sodium hydroxide solution, and finally add 5 parts of nano-chitosan and 1 part of sodium stearate to the mixed solution B, stir evenly, and obtain molten popping beads after ultrasonically removing air bubbles wall material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com