A kind of magnet vertical press molding method and its molding equipment

A technology of press forming and forming equipment, applied in the field of magnet vertical press forming method and forming equipment, can solve the problems of waste of cutting loss, unstable quality of magnets in the same batch, uneven distribution of forming materials, etc. The effect of stabilizing product quality and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

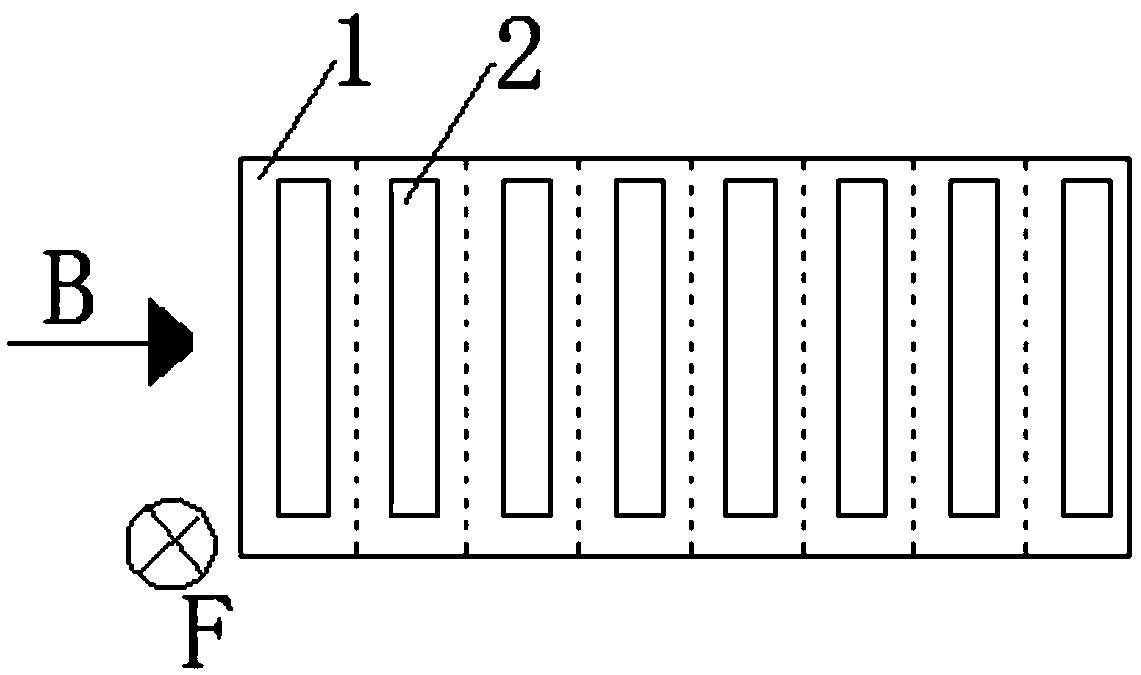

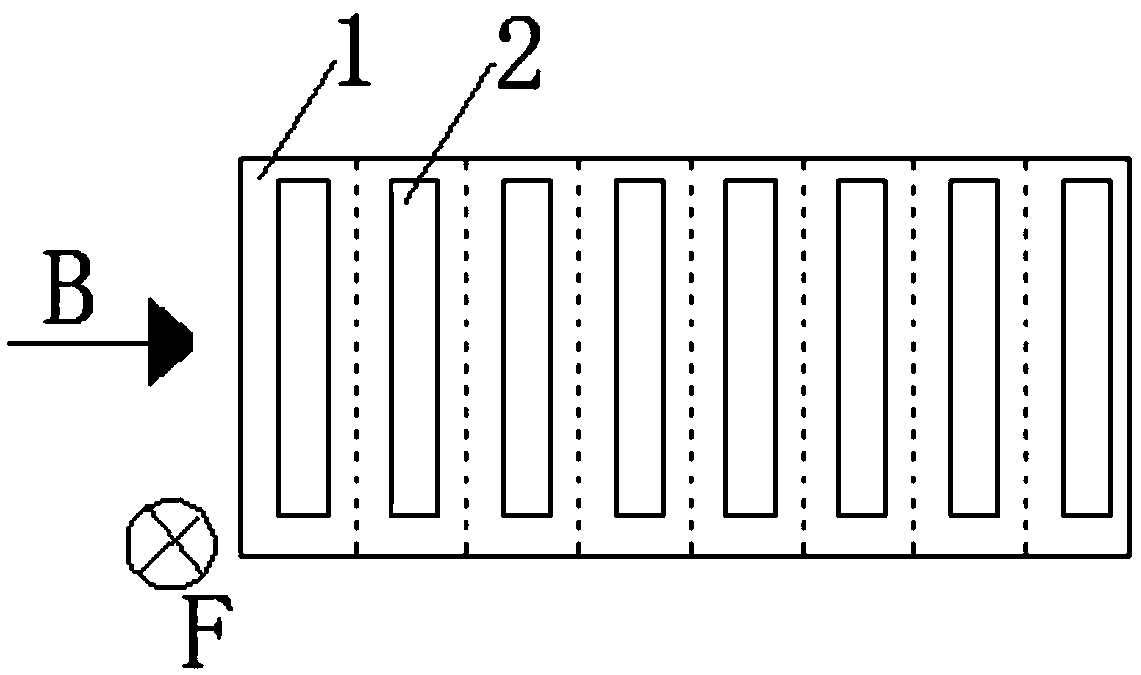

[0024] In the compression molding method of this embodiment, the mold used for the compression has a molding structure, and the magnetic blank is formed in the molding structure, and is pressed in a magnetic field to realize compression molding, wherein the direction of the magnetic field is perpendicular to the direction of the pressure.

[0025] Different from the above embodiments including but not limited to, the molded structure has a plurality of basic pressure chambers (that is, the number of basic pressure chambers is one, two, three, four, five and more), and in the molded structure A plurality of mutually independent basic pressure chambers are formed in one direction and stacked into a row of unit structures (that is, the number of mutually independent basic pressure chambers formed on a row of unit structures is one, two, three, four, five and more multiple), and at least one column of unit structures is set in the molded structure (ie, the number of unit structures...

Embodiment 2

[0034] The forming equipment in this embodiment includes a mould. The mold has at least a female mold and a male mold. The magnetic blank is pressed and magnetized in the mold cavity formed by the female mold and the male mold. The direction of the magnetizing magnetic field is related to the pressing pressure The direction is vertical, the mold has a plurality of mutually independent mold cavities (that is, the number of mold cavities is one, two, three, four, five and more), and the mold cavity is formed in one direction of the mold with multiple Independent mold cavities (that is, the number of mold cavities in one direction of the mold is one, two, three, four, five and more) and stacked into a mold unit structure, while the mold is set There is at least one column of mold unit structures (i.e. the number of mold unit structures is one, two, three, four, five and more columns): when the mold unit structure has multiple columns (i.e. the number of mold unit structures is two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com