Method for preparing machine-made charcoal from waste wood and bamboo

A technology of mechanism charcoal and carbonization, applied in the direction of carbon preparation/purification, can solve the problems of waste of wood resources, low recovery rate and recycling rate, low utilization rate, etc., to save resources, improve carbonization degree, carbon content high volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

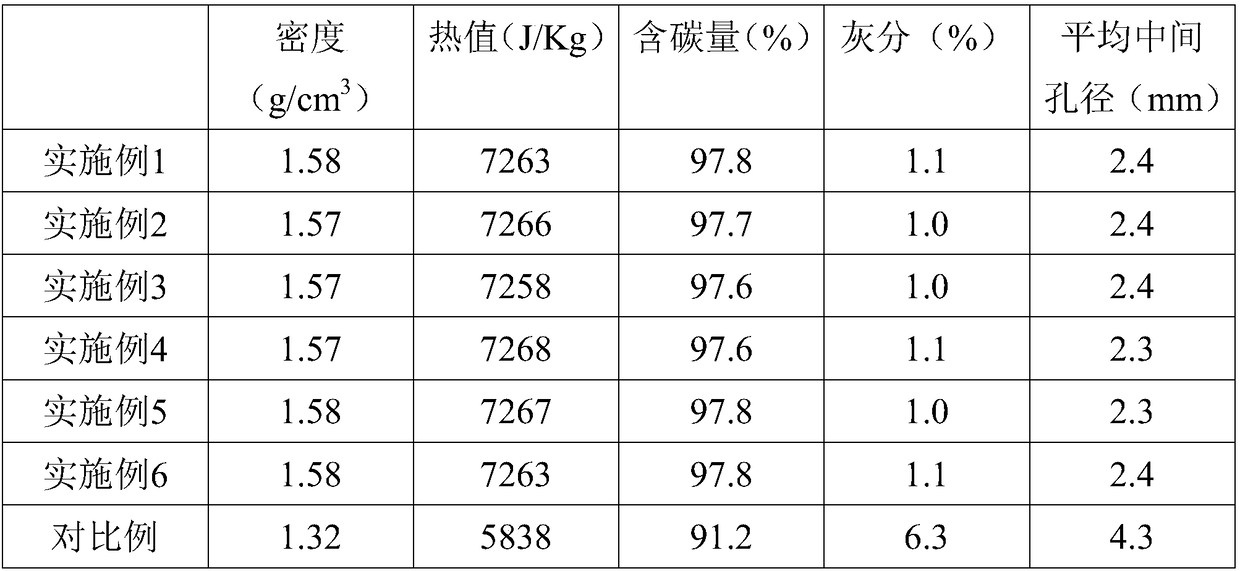

Examples

Embodiment 1

[0031] A kind of method utilizing waste wood bamboo to prepare mechanism charcoal, comprises the following steps:

[0032] (1) Pulverize the waste wood and bamboo, dissolve it in 2mol / L ammonia solution and carry out ultrasonic stirring at 45°C. After ultrasonic stirring, clean the solution with deionized water to become neutral. The ultrasonic frequency is 40KHz, the power is 80W, and the stirring speed is 100r / min;

[0033] (2) Mix the waste wood and bamboo powder after the lye treatment with 0.3% cellulase by powder weight, and react at 33° C.;

[0034] (3) Mix the above-mentioned reacted product with sorghum stalk powder, corn stalk powder, glycerin, and urea-aldehyde resin, and put it into a high-speed mixer for stirring, and the stirring speed is 700r / min; waste wood and bamboo powder and sorghum stalk powder, The mass ratio of corn stalk powder, glycerol, and urea-formaldehyde resin is 200:20:20:10:3;

[0035] (4) the mixture after the high-speed stirring is stamped i...

Embodiment 2

[0038] A kind of method utilizing waste wood bamboo to prepare mechanism charcoal, comprises the following steps:

[0039] (1) Pulverize the waste wood and bamboo, dissolve it in 2mol / L potassium hydroxide solution, and carry out ultrasonic stirring at 55°C. After ultrasonic stirring, wash the solution with deionized water to become neutral. The ultrasonic frequency is 40KHz, and the power is 80W. Stir The speed is 100r / min;

[0040] (2) Mix the waste wood and bamboo powder after the lye treatment with 0.3% cellulase by powder weight, and react at 34° C.;

[0041] (3) Mix the above-mentioned reacted product with sorghum stalk powder, corn stalk powder, glycerin, and urea-aldehyde resin, and put it into a high-speed mixer for stirring, and the stirring speed is 750r / min; waste wood and bamboo powder and sorghum stalk powder, The mass ratio of corn stalk powder, glycerol, and urea-formaldehyde resin is 60:6:6:4:1;

[0042] (4) the mixture after the high-speed stirring is stamp...

Embodiment 3

[0045] A kind of method utilizing waste wood bamboo to prepare mechanism charcoal, comprises the following steps:

[0046] (1) Pulverize the waste wood and bamboo, dissolve it in 2mol / L sodium hydroxide solution, and carry out ultrasonic stirring at 50°C. After ultrasonic stirring, wash the solution with deionized water to become neutral. The ultrasonic frequency is 40KHz, and the power is 80W. Stir The speed is 100r / min;

[0047] (2) Mix the waste wood and bamboo powder after the lye treatment with 0.3% cellulase by powder weight, and react at 32° C.;

[0048] (3) Mix the above-mentioned reacted product with sorghum stalk powder, corn stalk powder, glycerin, and urea-aldehyde resin, and put it into a high-speed mixer for stirring, and the stirring speed is 800r / min; waste wood and bamboo powder and sorghum stalk powder, The mass ratio of corn stalk powder, glycerol, and urea-formaldehyde resin is 250:25:25:15:4;

[0049] (4) the mixture after the high-speed stirring is stam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com