Self-compacting concrete prepared from recycled aggregate and preparation method thereof

A technology of self-compacting concrete and recycled aggregate, applied in the field of building materials, can solve the problems of increased water-cement ratio in the transition zone of the interface of new cement mortar, decreased mechanical properties of concrete materials, poor compaction performance of recycled aggregate, etc. Dispersion effect, improving mechanical strength, improving the effect of dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

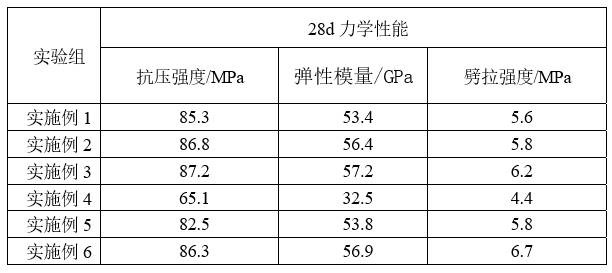

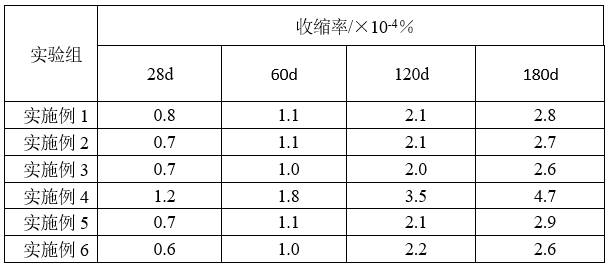

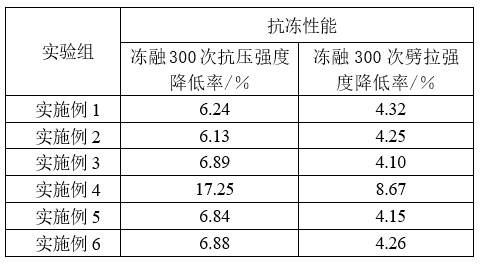

Examples

Embodiment 1

[0031] In parts by weight, weigh 45 parts of acetone, 10 parts of nano-silicon carbide and 3 parts of silane coupling agent KH-560 and place them in a stirring device, stir and mix and adjust the pH to 4.5 with triethylamine, collect the mixed solution and Place it under 200W for ultrasonic dispersion for 10min, collect the dispersed suspension and dry it at 200°C for 3h, let it cool down to room temperature and grind it to obtain modified nano-silicon carbide particles;

[0032] According to the mass ratio of 1:3:15, add the modified nano-silicon carbide particles and fly ash to the water glass with a solid content of 28%, stir and mix, place it under 200W for ultrasonic dispersion for 10min, and collect the coating modification solution; Take the recycled aggregate and add the recycled aggregate to the coating modification solution according to the mass ratio of 1:5, pressurize to 3MPa, soak under pressure for 25min, then ultrasonically vibrate at 200W for 25min, take out and...

Embodiment 2

[0034] In terms of parts by weight, weigh 47 parts of acetone, 12 parts of nano-silicon carbide and 4 parts of silane-coupled KH-560 and place them in a stirring device, stir and mix and adjust the pH to 4.7 with triethylamine, collect the mixed solution and place Ultrasonic disperse at 250W for 12min, collect the dispersed suspension and dry it at 210°C for 4h, let it cool down to room temperature and grind it to obtain modified nano-silicon carbide particles;

[0035] According to the mass ratio of 1:3:15, add the modified nano-silicon carbide particles and fly ash to the water glass with a solid content of 28%, stir and mix, place it under 250W for ultrasonic dispersion for 12min, and collect the coating modification solution; Take the recycled aggregate and add the recycled aggregate to the coating modification solution according to the mass ratio of 1:5, pressurize to 4MPa, soak under pressure for 27min, and then ultrasonically vibrate at 250W for 27min, take out and soak T...

Embodiment 3

[0038] In terms of parts by weight, weigh 50 parts of acetone, 15 parts of nano-silicon carbide and 5 parts of coupling agent and place them in a stirring device, stir and mix and adjust the pH to 5.0 with triethylamine, collect the mixed solution and place it under 300W Ultrasonic dispersion for 15 minutes, collecting the dispersion suspension and drying at 220°C for 5 hours, standing to cool to room temperature and grinding and pulverizing to obtain modified nano-silicon carbide particles;

[0039] According to the mass ratio of 1:3:15, add the modified nano-silicon carbide particles and fly ash to the water glass with a solid content of 28%, stir and mix, place it under 300W for ultrasonic dispersion for 15min, and collect the coating modification solution; Take the recycled aggregate and add the recycled aggregate to the coating modification solution according to the mass ratio of 1:5, pressurize to 5MPa, soak for 30min under pressure, and then ultrasonically vibrate at 300...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com