New-type tobacco flue-curing room and the tobacco flue-curing process

A technology of flue-cured tobacco room and smoke room, which is applied in the direction of tobacco, tobacco preparation, application, etc. It can solve the problems of high labor intensity, many natural conditions, uneven thickness of leaves, etc., so as to improve production and quality, eliminate fire hazards, Reduce the effects of working at heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

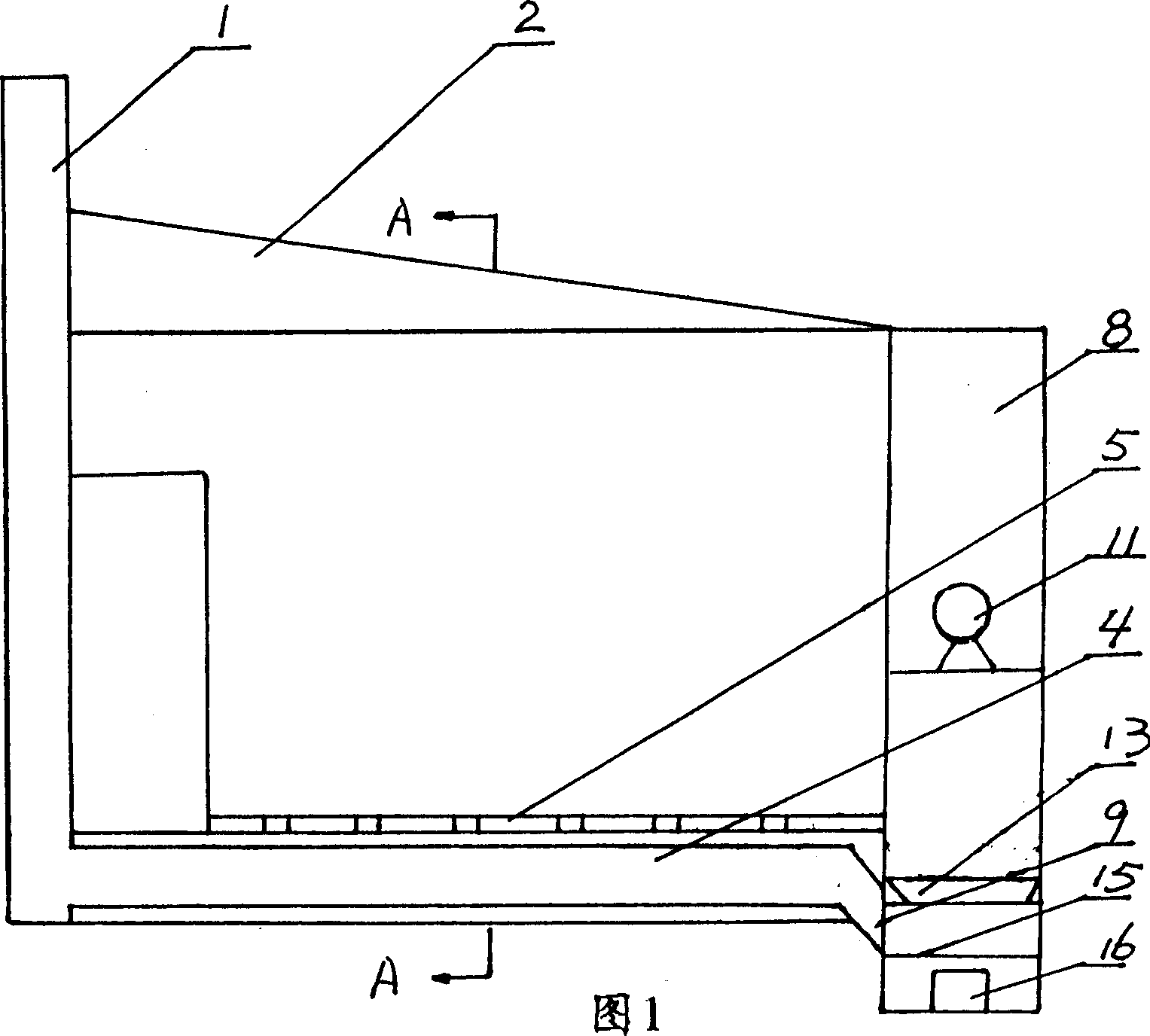

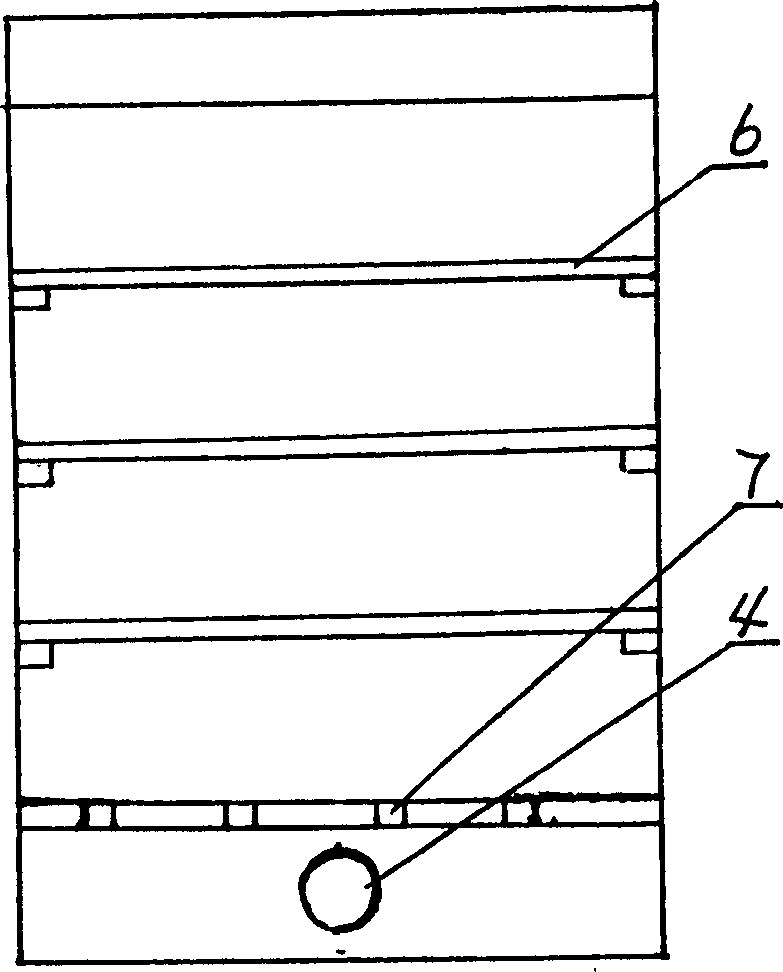

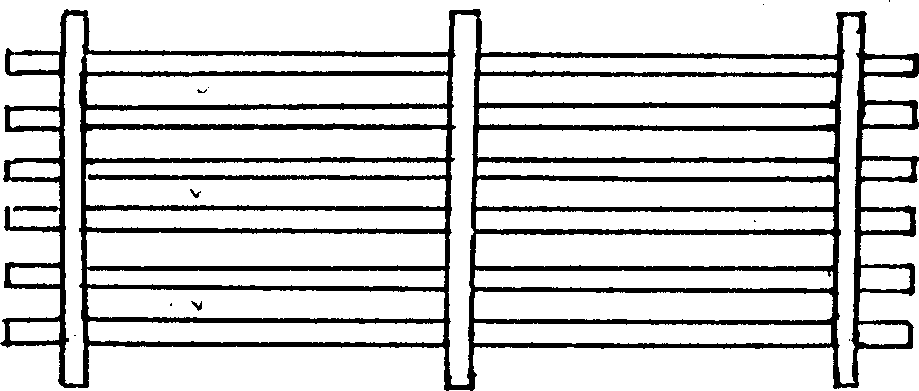

[0020] As shown in the figure, the novel flue-cured tobacco room of the present invention has length×width=6×2m 2 The height of one side is 2.3m, and the height of one side is 2.6m. The roof is inclined, and there are one door and two windows. , one high and one low. A boiler is installed on one side of the smoke room, and a flue 1 is installed on the other side. The boiler is installed below the ground, and the furnace bar 15 is installed in the furnace. In the smoke room, it communicates with the flue 1, the top of the flue is higher than the top of the smoke room, the furnace tube can be installed below the ground or above the ground, and the air distribution plate 5 is arranged above the furnace tube, and the small air distribution plate is evenly arranged The hole 7 and the air distribution plate isolate the heat source from the smoke rack 6, and make the tobacco leaves on the smoke rack 6 evenly heated. An air duct 8 is arranged above the boiler, the top of the air duc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com