Bulk-curing-bam curing method for improving curing quality of K326 tobacco

A curing method and dense curing room technology, applied in the fields of tobacco, tobacco preparation, application, etc., to achieve strong operability, improve the quality of curing, and reduce the effect of bad smoke and hanging gray smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

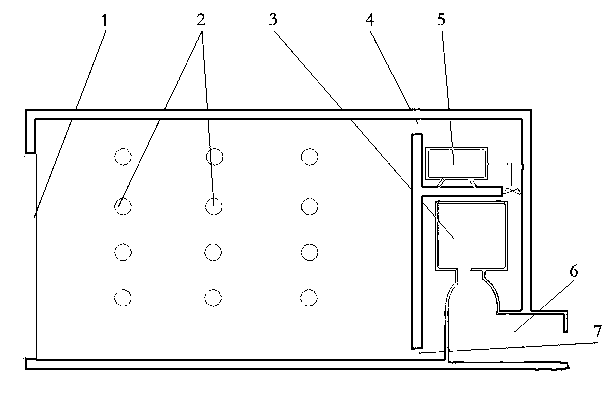

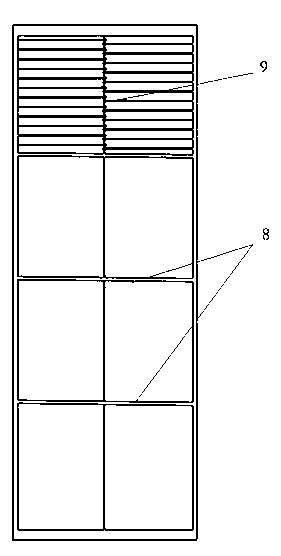

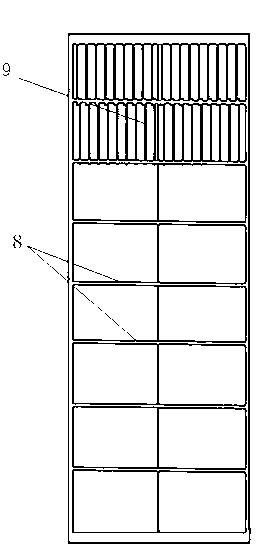

[0025] The smoke loading method of the baking process of the present invention is to make the direction of the tobacco rod the same as the wind direction of the air inlet, such as figure 2 As shown, the post-curing after loading the smoke includes six stages:

[0026] Step 1: After loading the tobacco leaves into the furnace, ignite the fire, raise the temperature of the dry bulb to 35°C within 4 hours, and control the temperature of the wet bulb at 35°C, and then stabilize the temperature for 8 hours, so that the tip of the tobacco leaves turns yellow by 3 cm, and the leaves become sweaty. soft. The goal of this stage is to warm and sweat the tobacco leaves just loaded into the barn, create a humidity environment for the tobacco leaves to turn yellow, and prevent the tobacco leaves from "hard and yellow".

[0027] Step 2: When the changes of the tobacco leaves meet the requirements of the first step, raise the dry bulb temperature to 38°C at a rate of 1°C / h, while controlli...

Embodiment 2

[0038] The smoke loading method of the baking process of the present invention is to make the direction of the tobacco rod the same as the wind direction of the air inlet, such as figure 2 As shown, the post-curing after loading the smoke includes six stages:

[0039] Step 1: After loading the tobacco leaves into the furnace, ignite the fire, raise the temperature of the dry bulb to 34°C within 4 hours, and control the temperature of the wet bulb at 33°C, and then stabilize the temperature for 8 hours, so that the tip of the tobacco leaves turns yellow by 3 cm, and the leaves become sweaty. soft. The goal of this stage is to warm and sweat the tobacco leaves just loaded into the barn, create a humidity environment for the tobacco leaves to turn yellow, and prevent the tobacco leaves from "hard and yellow".

[0040] Step 2: When the changes of the tobacco leaves meet the requirements of the first step, raise the dry bulb temperature to 38°C at a rate of 1°C / h, while controlli...

Embodiment 3

[0046] The smoke loading method of the baking process of the present invention is to make the direction of the tobacco rod the same as the wind direction of the air inlet, such as figure 2 As shown, the post-curing after loading the smoke includes six stages:

[0047] Step 1: After loading the tobacco leaves into the furnace, ignite the fire, raise the dry bulb temperature to 36°C within 4 hours, and control the wet bulb temperature at 34°C, and then stabilize the temperature for 8 hours, so that the tip of the tobacco leaves will turn yellow by 3 cm, and the leaves will sweat. soft. The goal of this stage is to warm and sweat the tobacco leaves just loaded into the barn, create a humidity environment for the tobacco leaves to turn yellow, and prevent the tobacco leaves from "hard and yellow".

[0048] Step 2: When the changes of the tobacco leaves meet the requirements of the first step, raise the dry bulb temperature to 38°C at a rate of 1°C / h, while controlling the wet bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com