Simulating guide system for fire-curing or flue-curing tobacco leaves

A guidance system and tobacco leaf technology, applied in tobacco, tobacco preparation, application, etc., can solve problems such as lack of experimental methods, inability to accurately compare and analyze, and difficult design and implementation, and achieve the effect of reducing economic losses and high grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

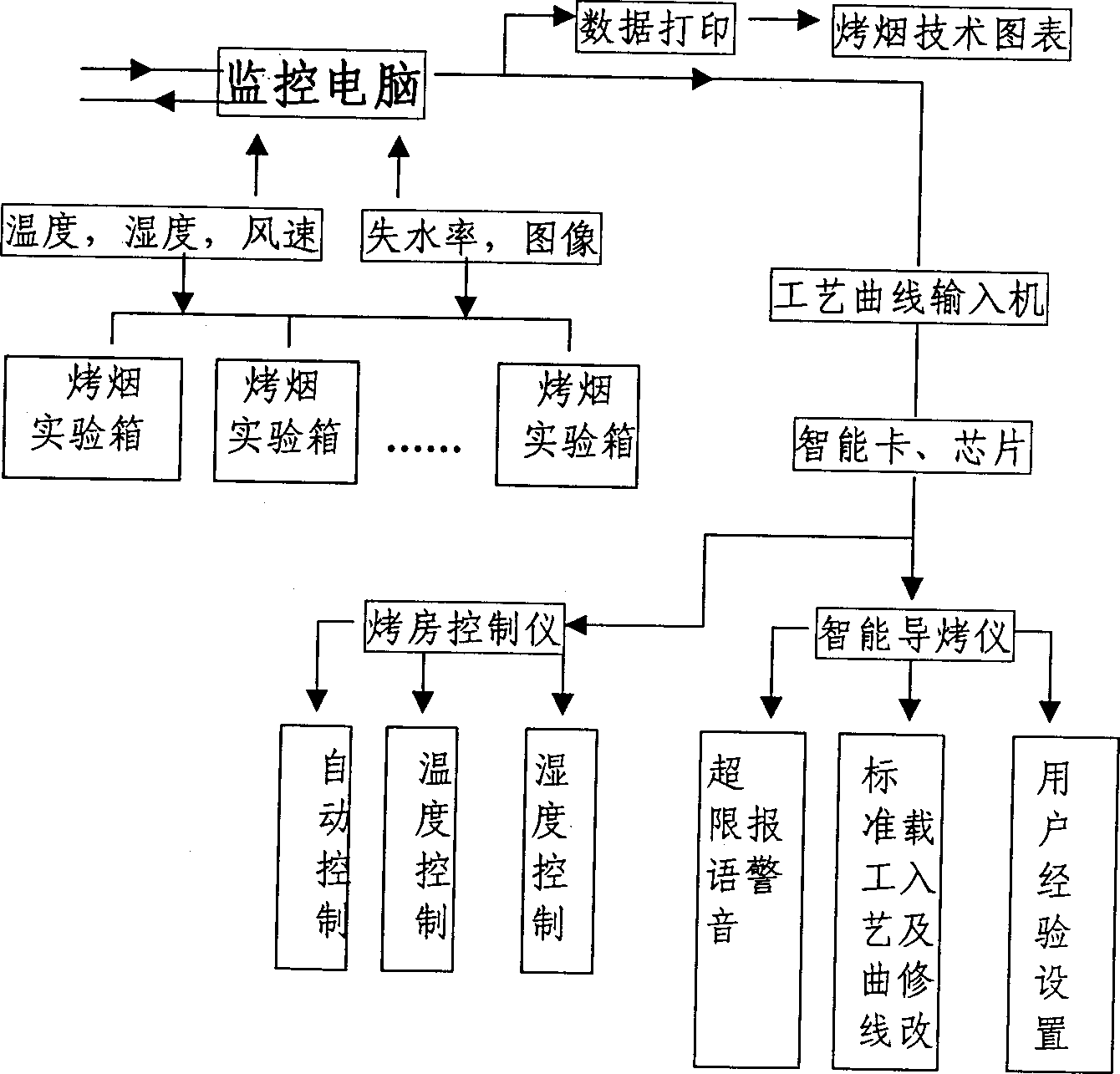

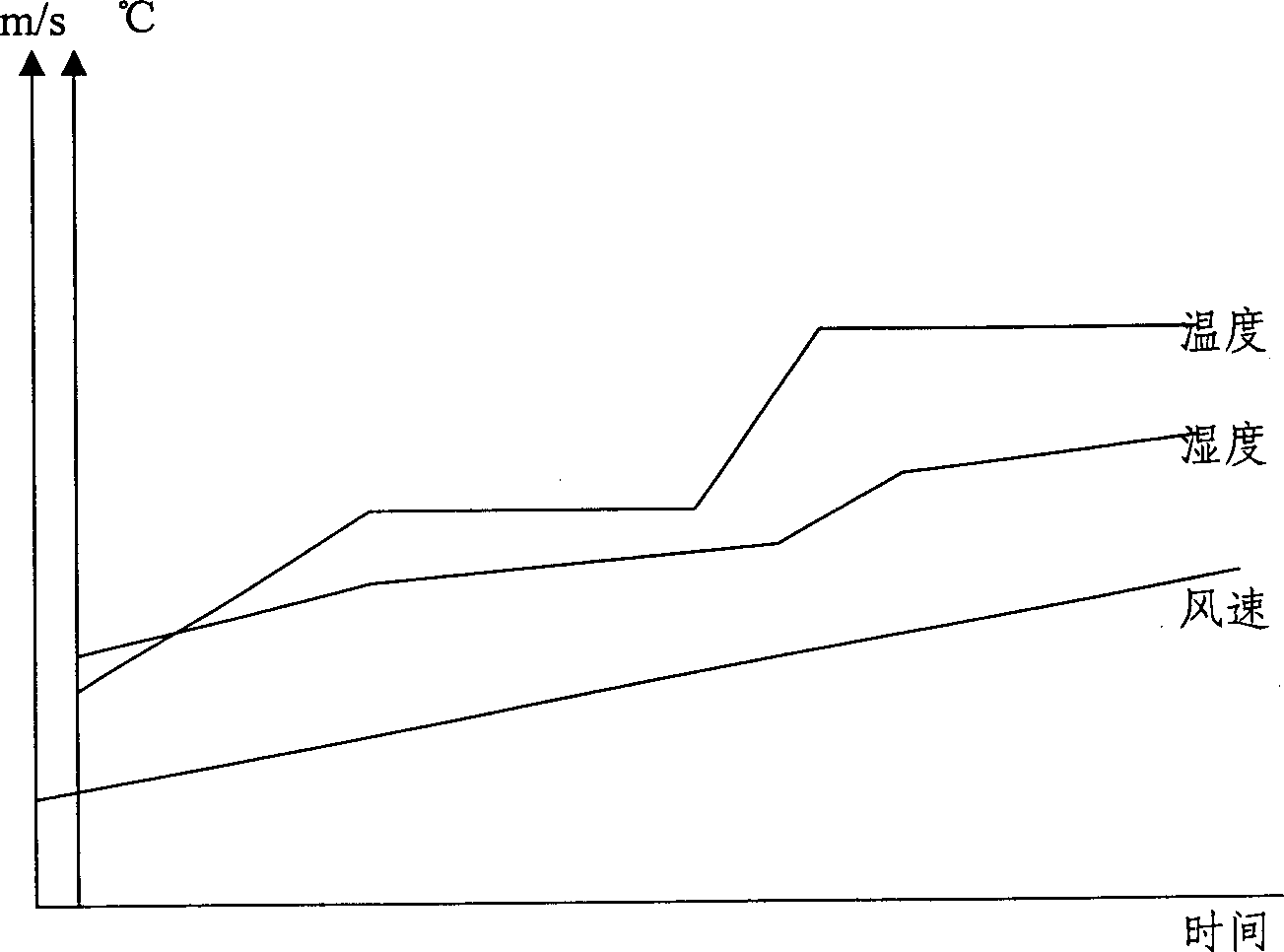

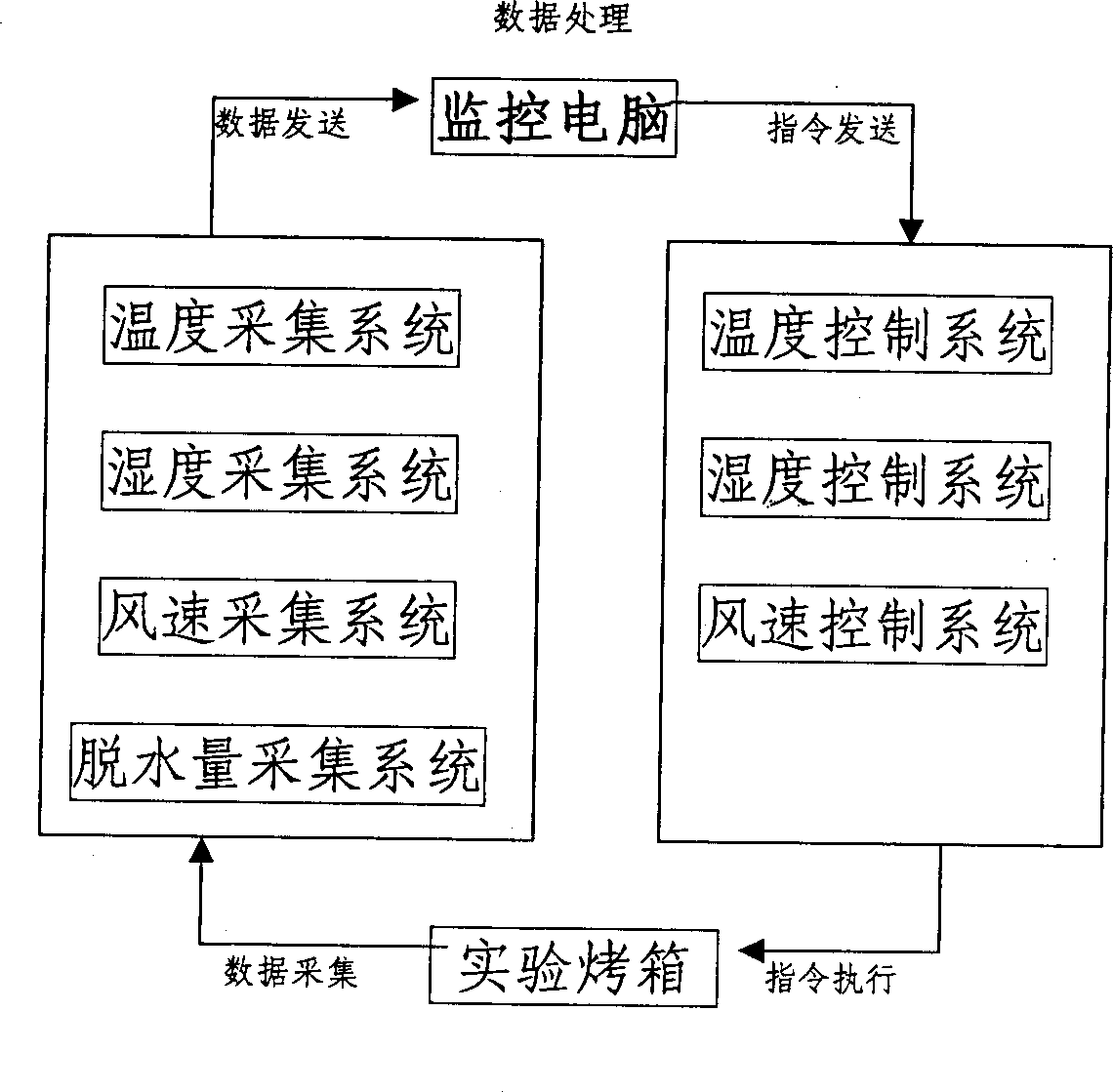

Method used

Image

Examples

Embodiment 1

[0061] Will come from Jiange, collected from the lower part of tobacco leaves, K 326 Tobacco leaves of various varieties are packed in three flue-cured tobacco test boxes, and different process curves are set on the monitoring computer for each flue-cured tobacco test box, and the tobacco leaves are experimentally cured.

[0062]Setting of the process curve on the monitoring computer: No. 1 test box uses the second expert process curve saved in the monitoring computer; No. 2 test box calls out the fifth process curve archived last year; No. 3 test box calls out the previous year’s file The third process curve, the monitoring computer automatically controls the flue-cured tobacco experiment box through the control cabinet, and compares the temperature, humidity, and wind speed parameter values collected from the temperature sensor, humidity sensor, and wind speed sensor in the flue-cured tobacco experiment box with the set process. The temperature, humidity, and wind speed pa...

Embodiment 2

[0065] Will originate from Henan, collect from the upper part of tobacco leaves, N c Tobacco leaves of 89 varieties; from Henan, collected from the lower part of tobacco leaves; tobacco leaves of Yunnan 85 varieties; from Henan, collected from the lower part of tobacco leaves, N c Tobacco leaves of 89 varieties are packed in 3 flue-cured tobacco test boxes, and for each flue-cured tobacco test box, the same process curve is set on the monitoring computer, and the tobacco leaves are experimentally cured.

[0066] The setting of the process curve on the monitoring computer adopts the method of separately calling out the process curves previously used for baking and archiving. The monitoring computer automatically controls the flue-cured tobacco experiment box through the control cabinet, and the temperature sensor, humidity sensor, wind speed The temperature, humidity, and wind speed parameter data collected by the sensor are compared with the temperature, humidity, and wind spe...

Embodiment 3

[0069] Will come from Jiange, collected from the middle of tobacco leaves, K 326 Tobacco leaves of various varieties; Tobacco leaves from Henan, collected from the lower part of the tobacco leaves, and Yunnan 85 varieties; , set different process curves on the monitoring computer, and carry out experimental baking on the tobacco leaves.

[0070] The setting of the process curve on the monitoring computer adopts the process curve method set by the user. The monitoring computer automatically controls the flue-cured tobacco experiment box through the control cabinet, and collects the temperature and humidity from the temperature sensor, humidity sensor, and wind speed sensor in the flue-cured tobacco experiment box. 1. Compare the wind speed parameter data with the temperature, humidity, and wind speed parameter data on the set process curve, and adjust the difference, so that the temperature, humidity, and wind speed in the flue-cured tobacco experiment box are constantly approa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com