Densification tobacco flue-cure dry-wet bulb temperature automatic control technique based on tobacco image processing

A dry-wet bulb temperature and image processing technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of tobacco leaf circulation economic loss, tobacco leaf baking instability, processing troubles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the technical solutions of the present invention, the implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

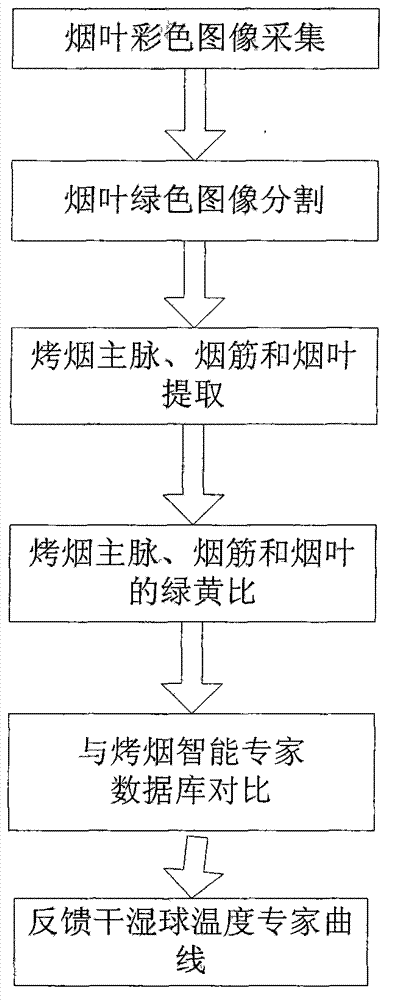

[0019] The flow of the present invention's intensive flue-cured tobacco wet and dry bulb temperature automatic control technology based on tobacco leaf image processing is as follows: figure 1 As shown, firstly, according to the three-stage curing process curve of intensive flue-cured tobacco and on-site curing experience, the intelligence of green and yellow ratios of tobacco leaves, tobacco tendons and main veins and dry-wet bulb temperature curves in the process of tobacco leaf curing was established. Expert database; adjust the light intensity of the incandescent lamp in the barn to ensure that the light in the barn meets the true color of the tobacco leaf image collected by the video camera; then binarize the green channel image of the colored tobacco leaf ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com